Truss translation device and truss mounting method

A technology of translation device and truss, which is applied in the direction of construction, building structure, and building material processing. It can solve the problems of inapplicability of conventional hoisting methods, difficult installation of truss structures, and small construction area, so as to improve project progress and construction efficiency. Speed, improve work efficiency, reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. However, it is to be noted that many of the details listed in the specification are merely in order to make the reader have a thorough understanding of the present invention, even if there is no such specific details, these aspects of the invention may be implemented.

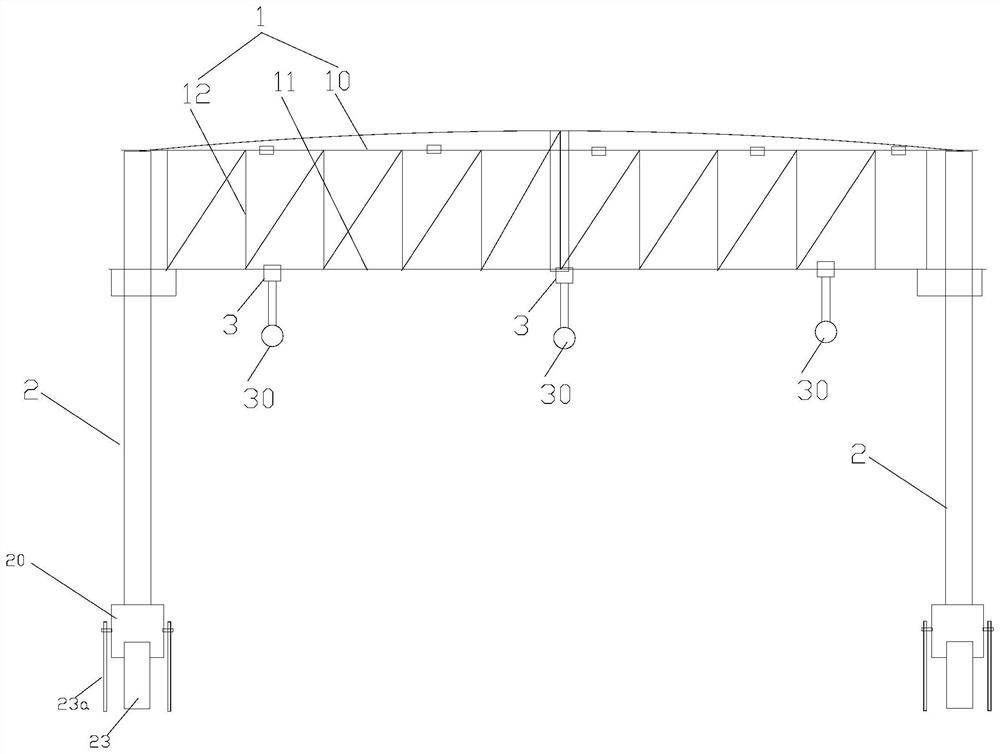

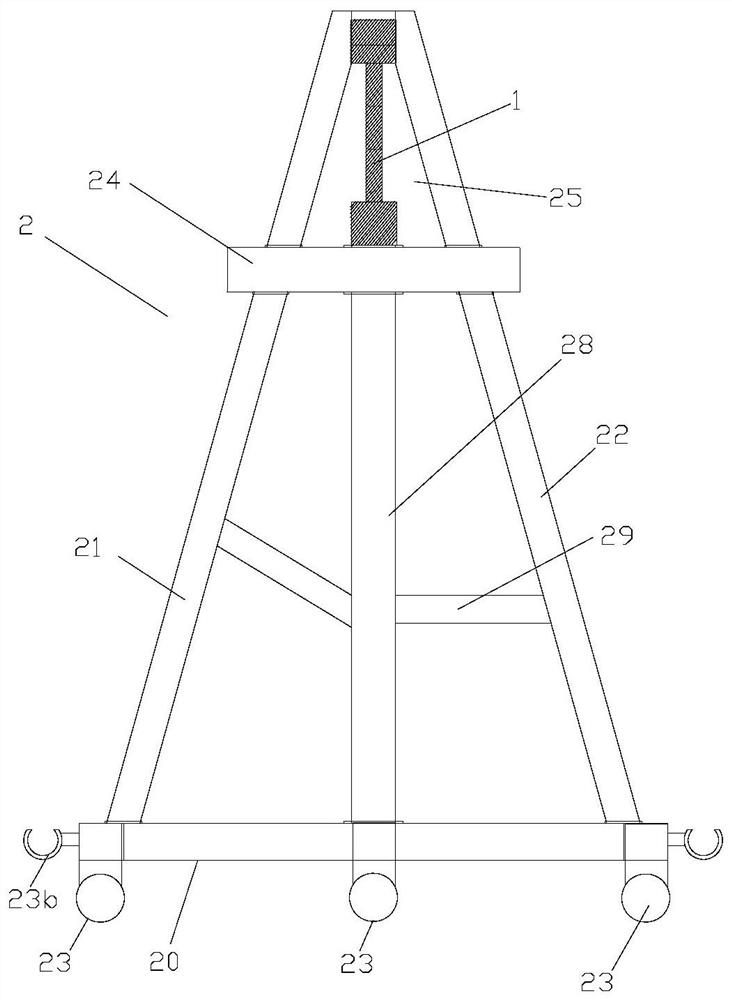

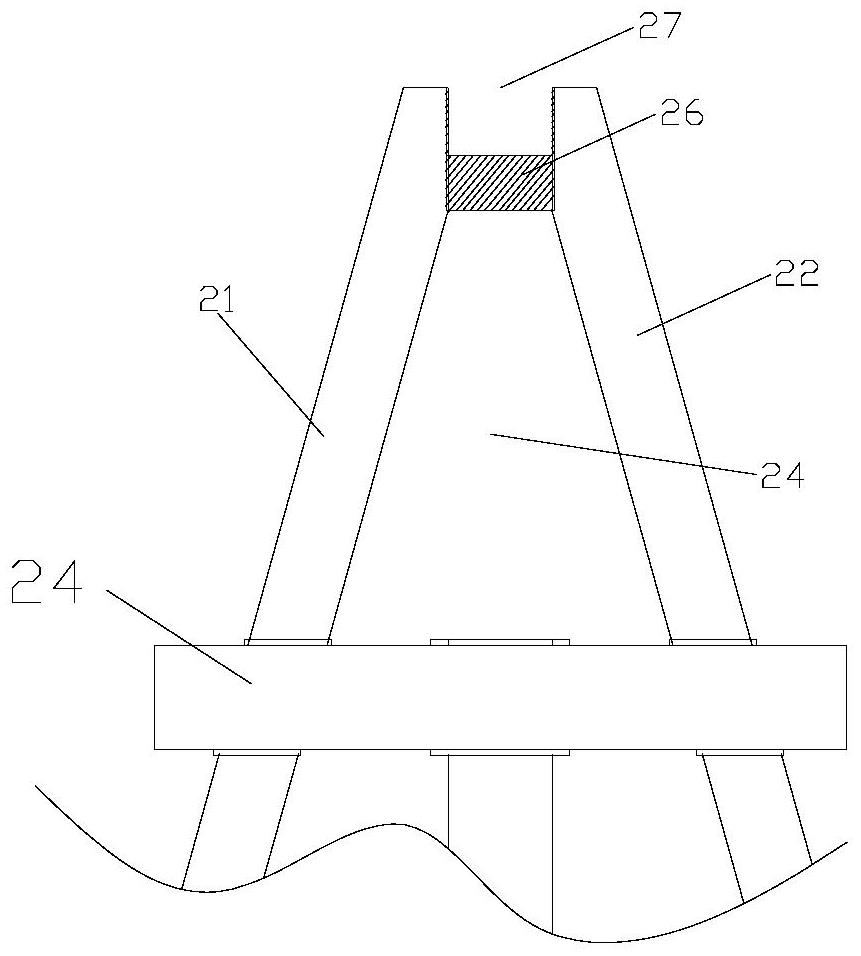

[0029] Combine figure 1 and figure 2 As shown, according to the present invention, the truss translation includes a truss body 1 and a support frame body 2 that is vertically connected to both ends of the truss main body 1, the support frame body 2 includes a support base beam 20, A support column 21, the second support post 22, and the traveling roller 23, the two ends of the support base beam 20 secure the lower end and the lower end of the first support post 21 and the lower end of the second support post 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com