A floating device and method

A technology of mounting parts and movable flanges, applied in the field of automation, can solve the problems of high cost, affecting the processing range, occupying the processing space of the machine tool, etc., to achieve the effects of improving stability, improving load utilization, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

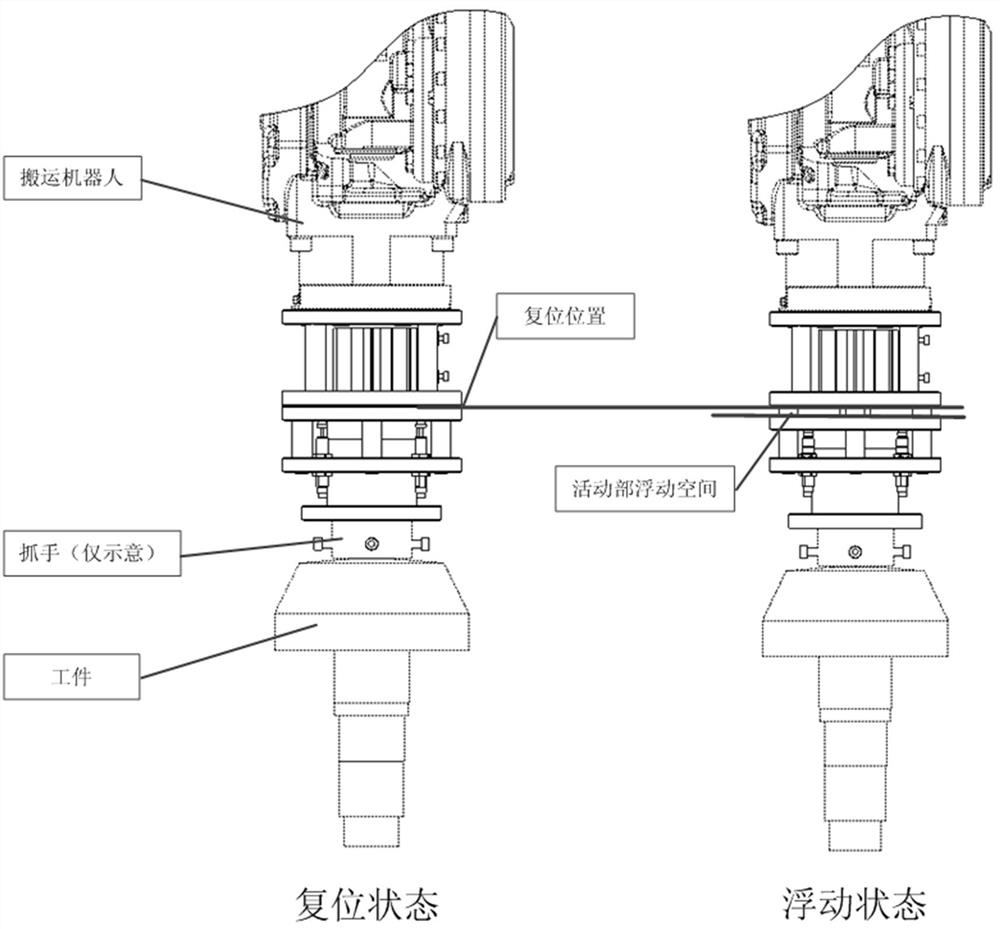

[0038] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] Explanation of related terms

[0040] Robot gripper: An actuator installed on the front end of a multi-joint robot or a Cartesian robot to grab a workpiece.

[0041] Hydraulic buffer: a safety buffer device that uses hydraulic damping to decelerate objects acting on it until it stops, preventing hard collisions.

[0042] Centering function: connect two or more rotating bodies and make their axis lines on the same line.

[0043] Reset function: After one or more objects have changed their positions and postures, restore them to their original positions and postures.

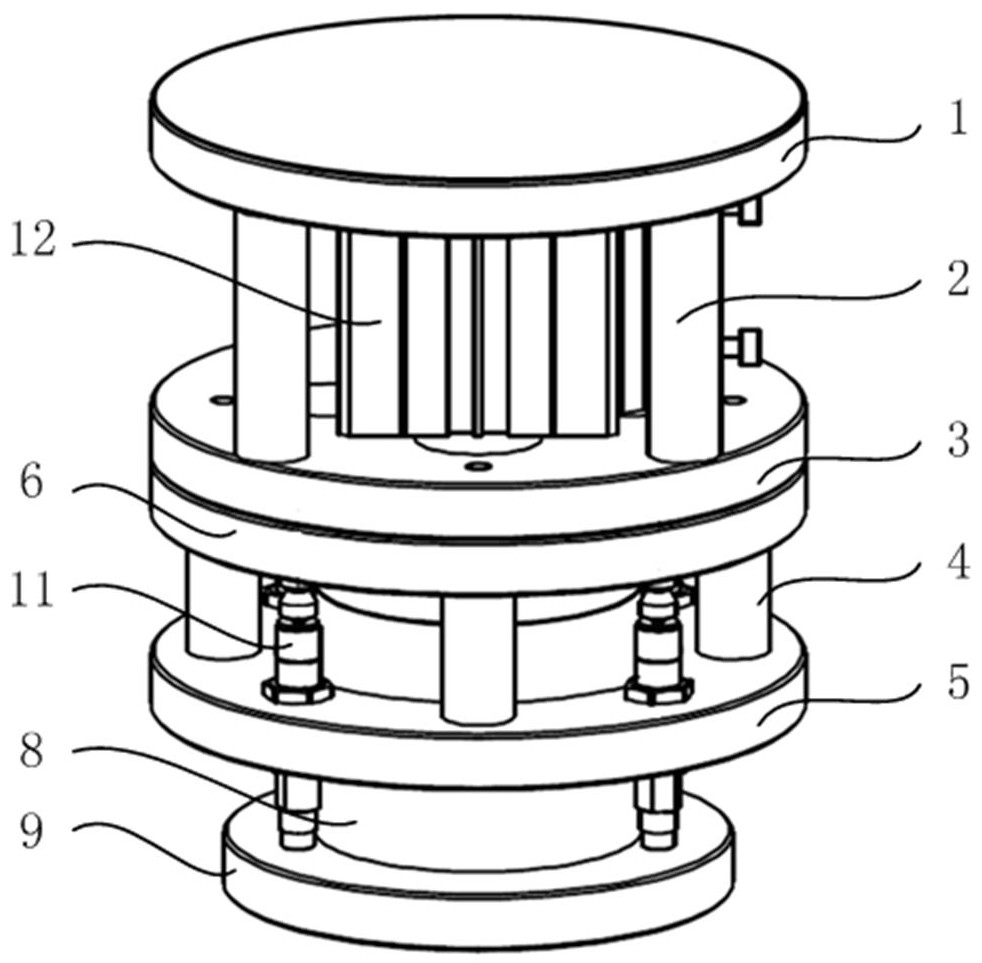

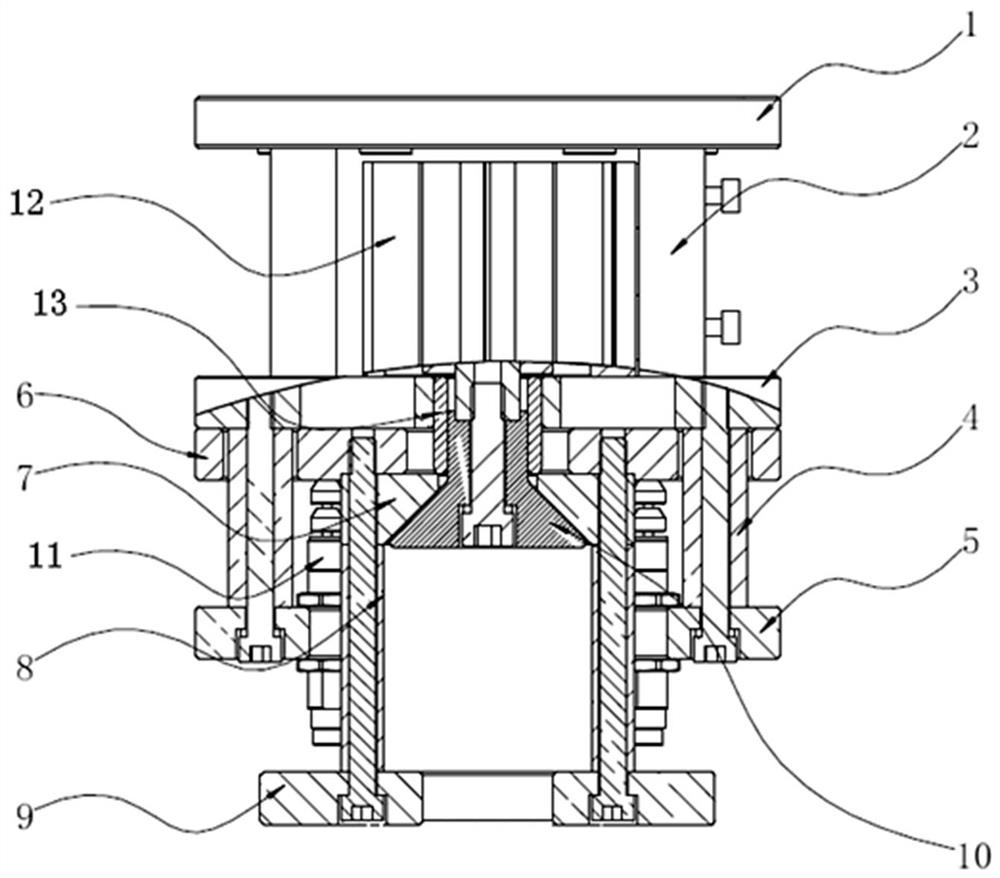

[0044] figure 1 It is a schematic diagram of the three-dimensional structure of the floati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap