A friction plug repair welding spindle head device

A spindle head and repair welding technology, which is applied in the field of welding manufacturing, can solve the problems of affecting welding quality, affecting the stability of motion, and easy fluctuation of pressure, and achieves the effect of green and clean welding environment, good natural heat dissipation conditions, and stable welding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

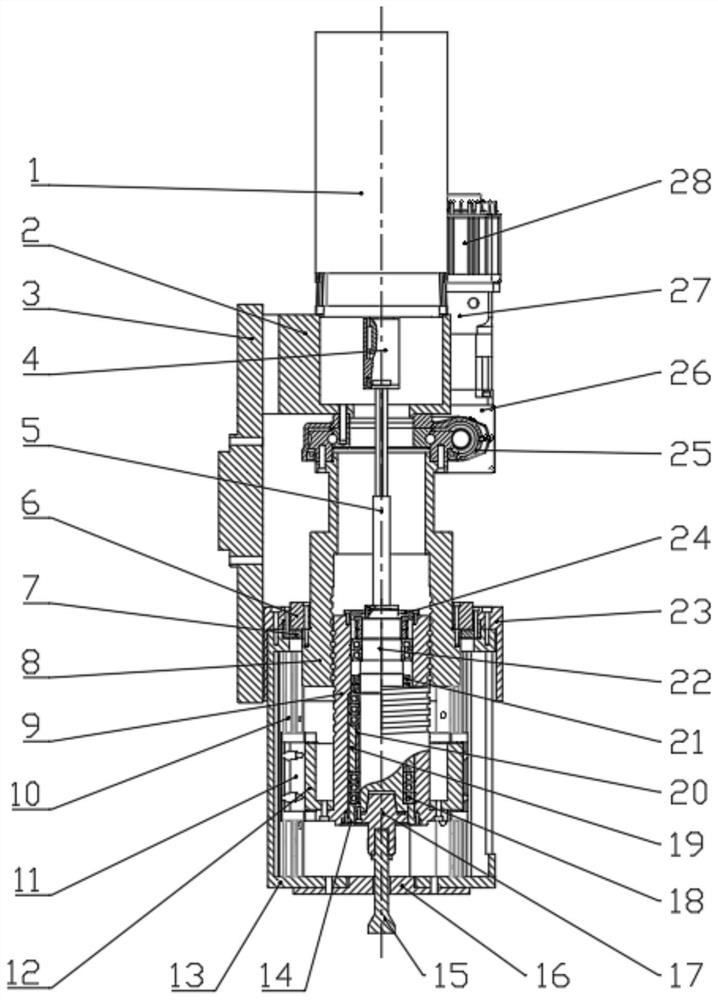

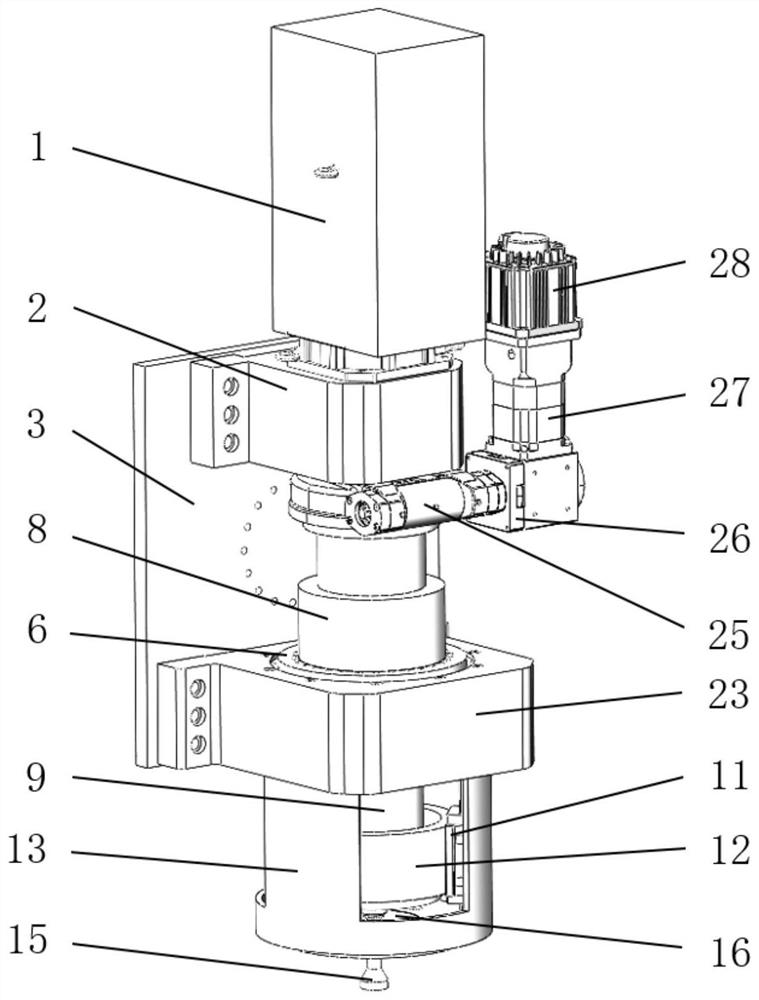

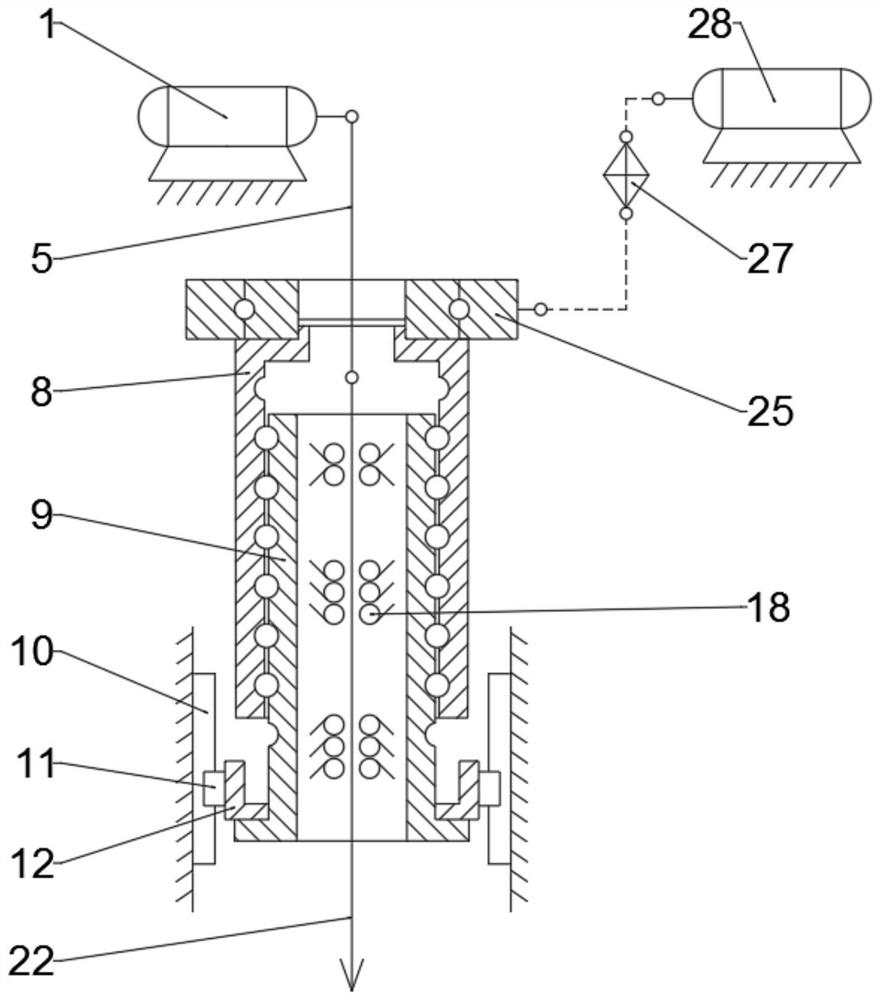

[0030]In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0031] as attached Figure 1 to Figure 5 As shown, a friction plug repair welding spindle head device includes a rotary drive system and an axial movement drive system.

[0032] The rotary drive system includes an AC servo rotating shaft motor 1, a shaft end sleeve 4 of the rotating shaft motor, a ball spline 5, a rotating shaft 22, a knife handle 17 and a stopper rod 15;

[0033] The main shaft output end of the AC servo shaft motor 1 is connected to the head end of the shaft end sleeve 4 of the shaft motor through a key, and the tail end of the shaft end sleeve 4 of the shaft motor is connected to the ball spline 5 through a bolt. The head end of the ball spline 5 is connected to the head end of the ball spline 5 through bolts to the head e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com