A processing method of ventilated Gangbao hot-melt film forming mold

A technology of hot-melt film and mold forming, which is applied in the field of mold processing, and can solve the problems of lack of heat dissipation space on the forefoot and obstruction of ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

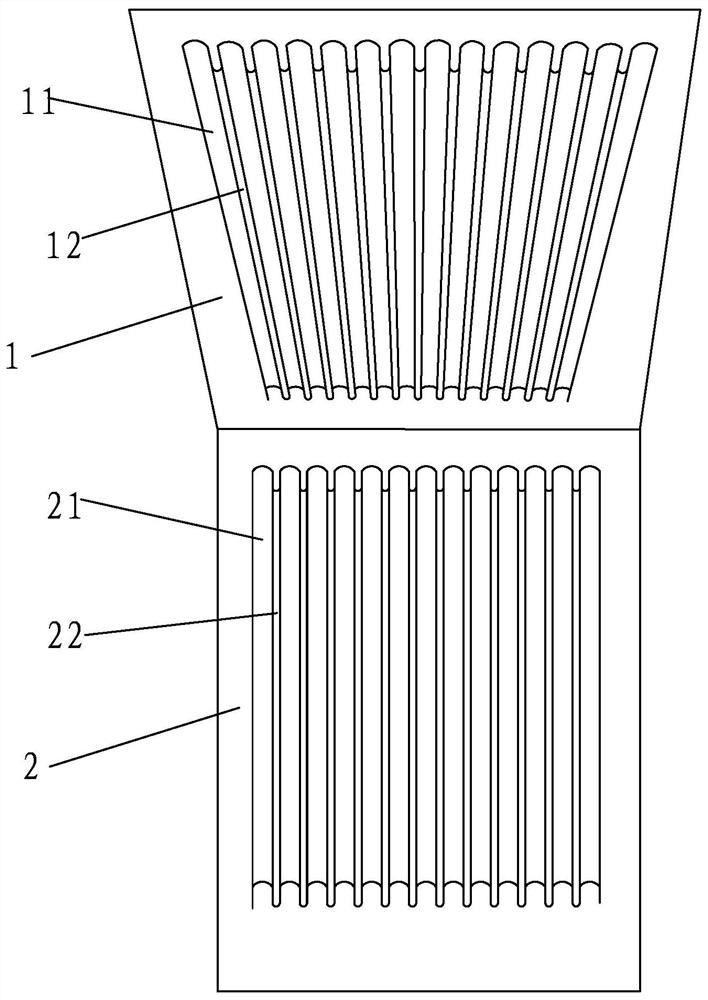

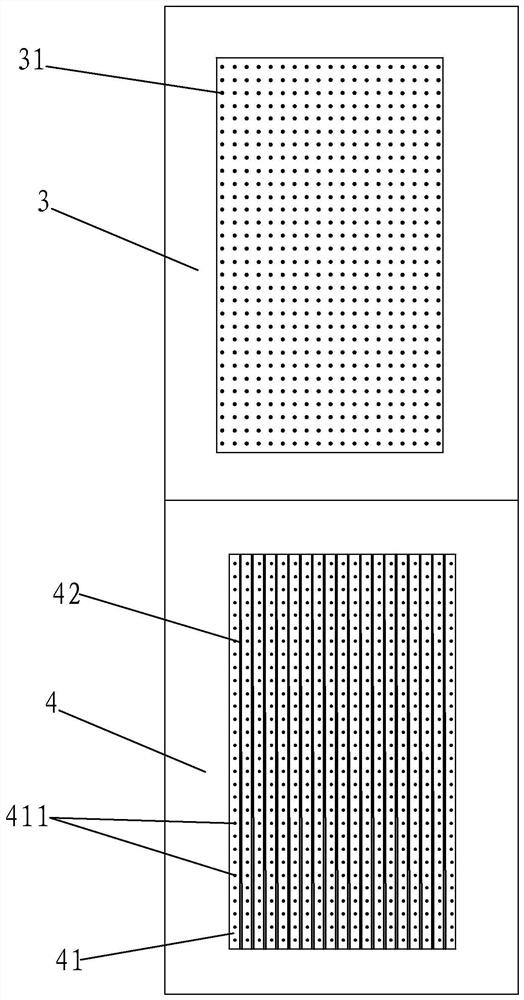

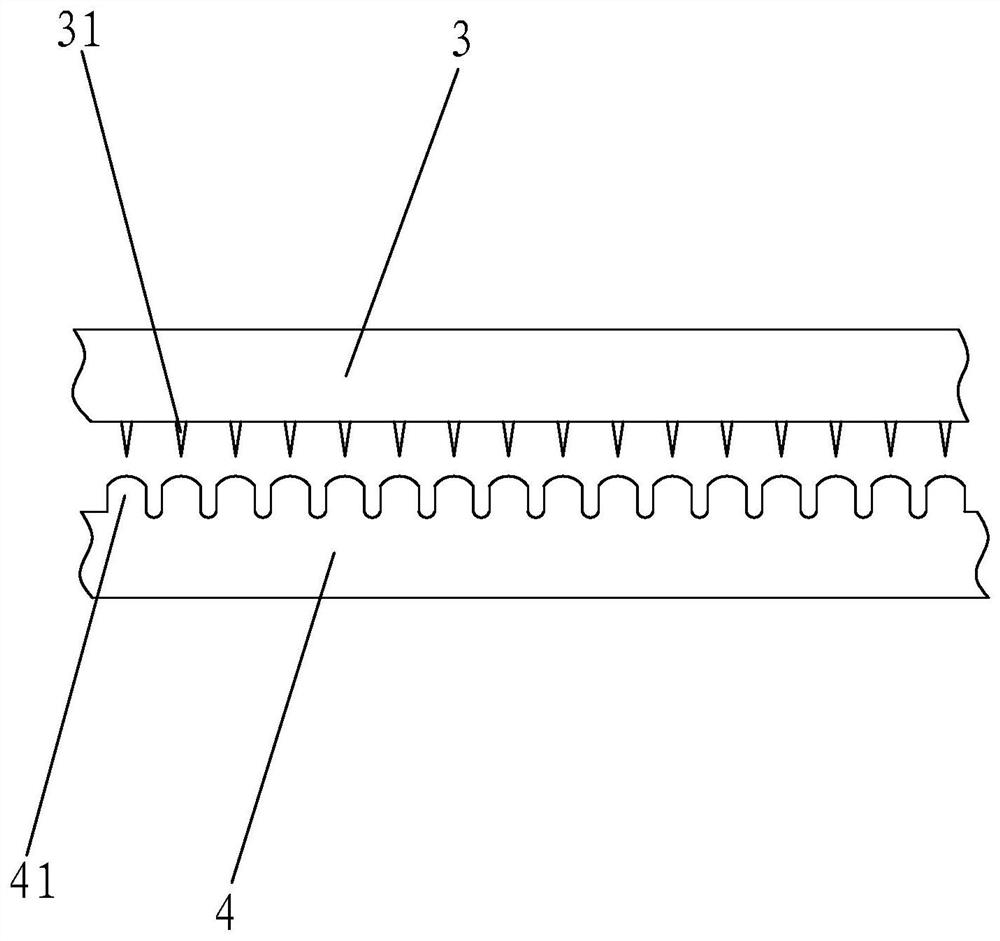

[0023] The processing method of a breathable Gangbao hot-melt film forming mold of the present invention is processed through the following steps:

[0024] Step 1: Data collection, the tester walks on the gait analysis platform wearing shoes, and the ultrasonic anemometer is used to collect the propagation direction of the contact sound in the air generated by the tester's foot and the contact surface of the shoe cavity while walking. It is concluded that the wind direction of the contact surface between the foot and the shoe cavity is upward and left and right during walking; this method uses the ultrasonic time difference method to measure the wind speed. Propagating in the air, the propagation speed of this sound is collected by the ultrasonic anemometer, and finally the wind direction of the contact surface between the foot and the shoe cavity is obtained, which lays the foundation for the exhaust direction;

[0025] Step 2. Scan the cross section of the existing Gangbao h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com