Transparent polyurethane paint for dyed veneer and preparation method of transparent polyurethane paint

A technology of polyurethane paint and polyurethane resin, applied in the field of polyurethane paint, can solve the problems of not being able to guarantee the viscosity, strength and drying speed at the same time, and achieve the effect of wide application range, convenient work and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

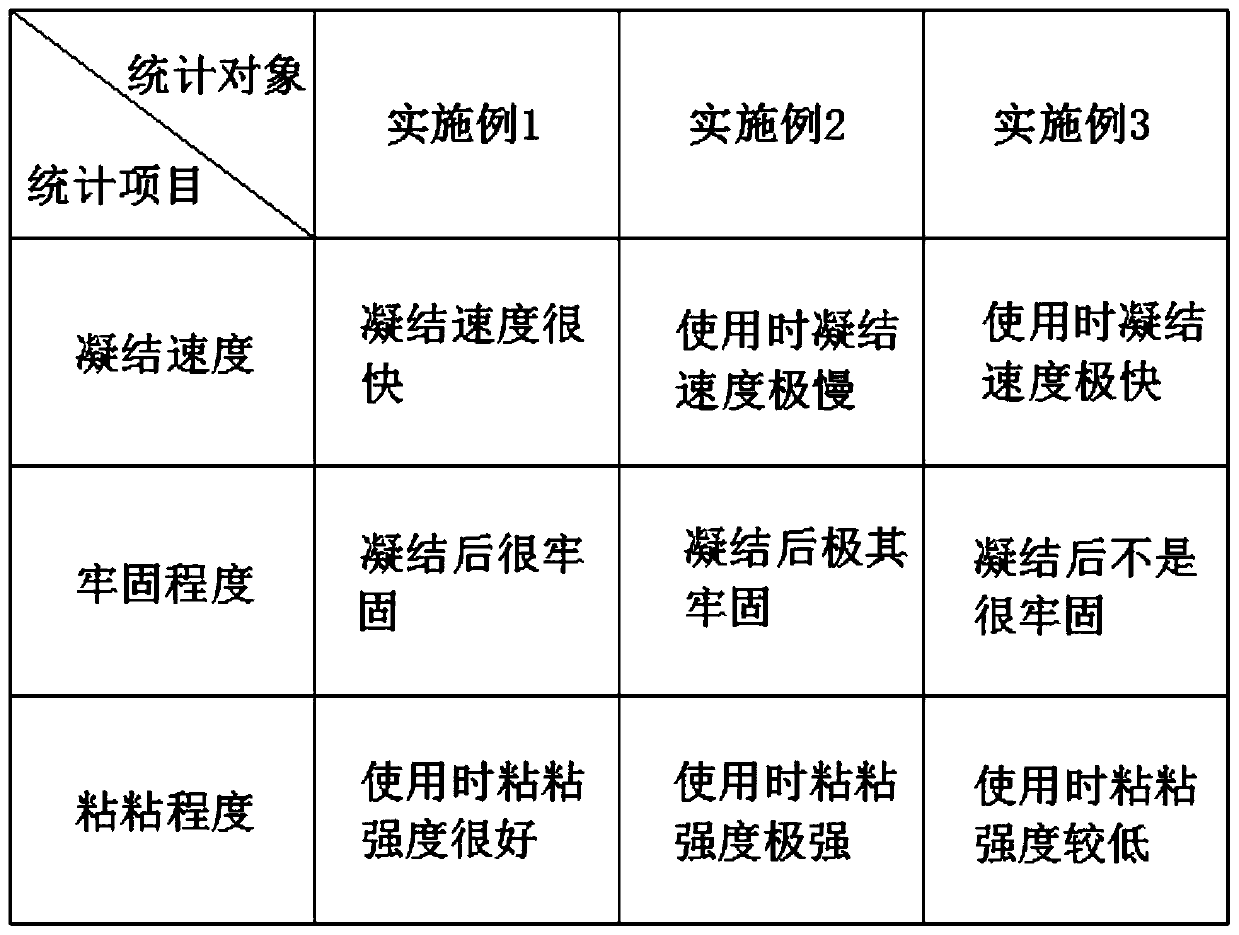

Embodiment 1

[0026] S1, 35 parts of polyurethane resin, 10 parts of xylene, 15 parts of butyl acetate, 4 parts of cyclohexanone, 6 parts of cyanoacetoxy compound, 5 parts of polyvinyl acetate emulsion, 10 parts of 107 glue, whitening agent 5 parts, 5 parts of flocculant, and 10 parts of clear water;

[0027] S2. Screen all the xylene, butyl acetate, cyclohexanone and cyanoacetoxy compounds to remove the impurities inside, and then use a filter to filter the clear water, and the whitening agent, flocculant, 107 Glue and polyvinyl acetate emulsion are taken out of the original packaging and do not need to be filtered;

[0028] S3. Before adding the flocculant, it is necessary to add a whitening agent. After adding the whitening agent, stir several times, and choose the standing time according to the mixing amount. After standing for 10 minutes, add the flocculant and fully mix and stir. After mixing Stand still again and wait for the flocculation to end;

[0029] S4. Take out the transpare...

Embodiment 2

[0033] S1, 30 parts of polyurethane resin, 20 parts of xylene, 10 parts of butyl acetate, 5 parts of cyclohexanone, 5 parts of cyanoacetoxy compound, 5 parts of polyvinyl acetate emulsion, 10 parts of 107 glue, whitening agent 4 parts, 6 parts of flocculant, and 5 parts of clear water;

[0034] S2. Screen all the xylene, butyl acetate, cyclohexanone and cyanoacetoxy compounds to remove the impurities inside, and then use a filter to filter the clear water, and the whitening agent, flocculant, 107 Glue and polyvinyl acetate emulsion are taken out of the original packaging and do not need to be filtered;

[0035] S3. Before adding the flocculant, it is necessary to add a whitening agent. After adding the whitening agent, stir several times, and choose the standing time according to the mixing amount. After standing for 10 minutes, add the flocculant and fully mix and stir. After mixing Stand still again and wait for the flocculation to end;

[0036] S4. Take out the transparen...

Embodiment 3

[0040] S1, 40 parts of polyurethane resin, 10 parts of xylene, 5 parts of butyl acetate, 5 parts of cyclohexanone, 4 parts of cyanoacetoxy compounds, 6 parts of polyvinyl acetate emulsion, 15 parts of 107 glue, and whitening agent 4 parts, 6 parts of flocculant, and 5 parts of clear water;

[0041] S2. Screen all the xylene, butyl acetate, cyclohexanone and cyanoacetoxy compounds to remove the impurities inside, and then use a filter to filter the clear water, and the whitening agent, flocculant, 107 Glue and polyvinyl acetate emulsion are taken out of the original packaging and do not need to be filtered;

[0042] S3. Before adding the flocculant, it is necessary to add a whitening agent. After adding the whitening agent, stir several times, and choose the standing time according to the mixing amount. After standing for 10 minutes, add the flocculant and fully mix and stir. After mixing Stand still again and wait for the flocculation to end;

[0043] S4. Take out the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com