Patents

Literature

30results about How to "Guaranteed adhesion strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imitated stainless steel aluminum surface treatment technology

ActiveCN102925948ABright colorFresh Time GuaranteedSurface reaction electrolytic coatingPretreated surfacesHardnessUltimate tensile strength

The invention discloses an imitated stainless steel aluminum surface treatment technology, relating to the technical field of aluminum surface treatment. The technological flow comprises the following steps of: (1) surface pretreatment: A, oil removal; B, dirt removal; C, anode oxidation; D, coloring; and E, primary hole sealing; (2) surface re-treatment: F, spraying of a mixed coating; and G, curing. The surface of the aluminum product after the treatment has relatively high hardness and strength as well as the characteristics of bright color, long maintaining time and the like; and the technology is suitable for treating panels and sections made from aluminum products and having various colors.

Owner:QIYANG HONGTAI ALUMINUM IND

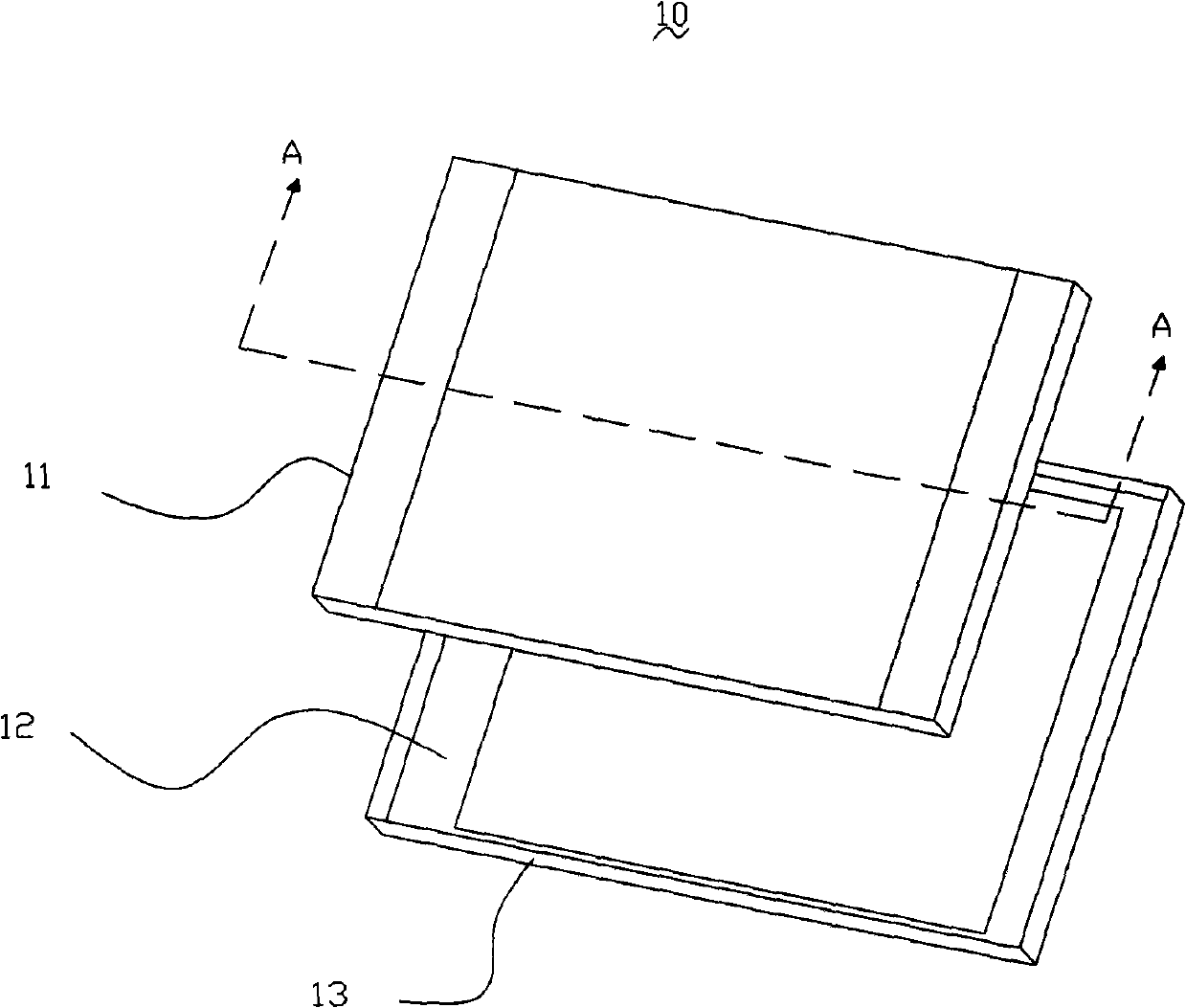

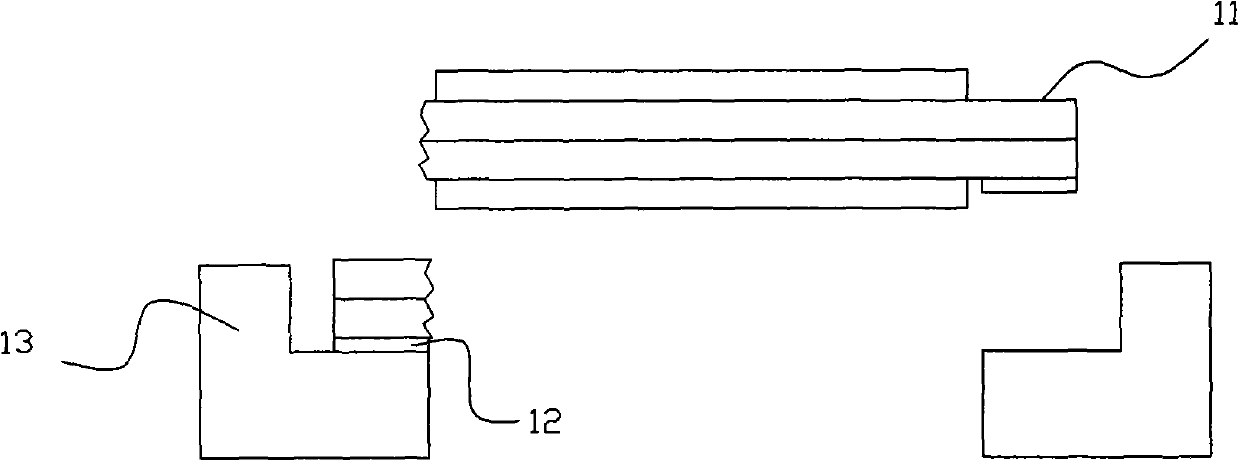

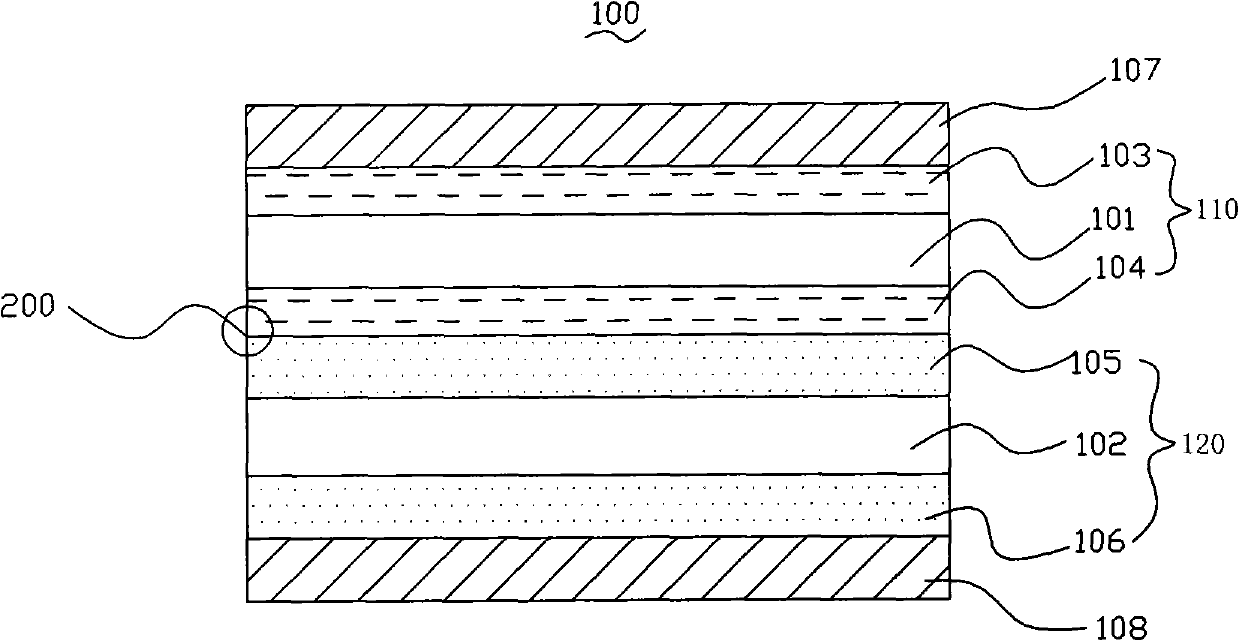

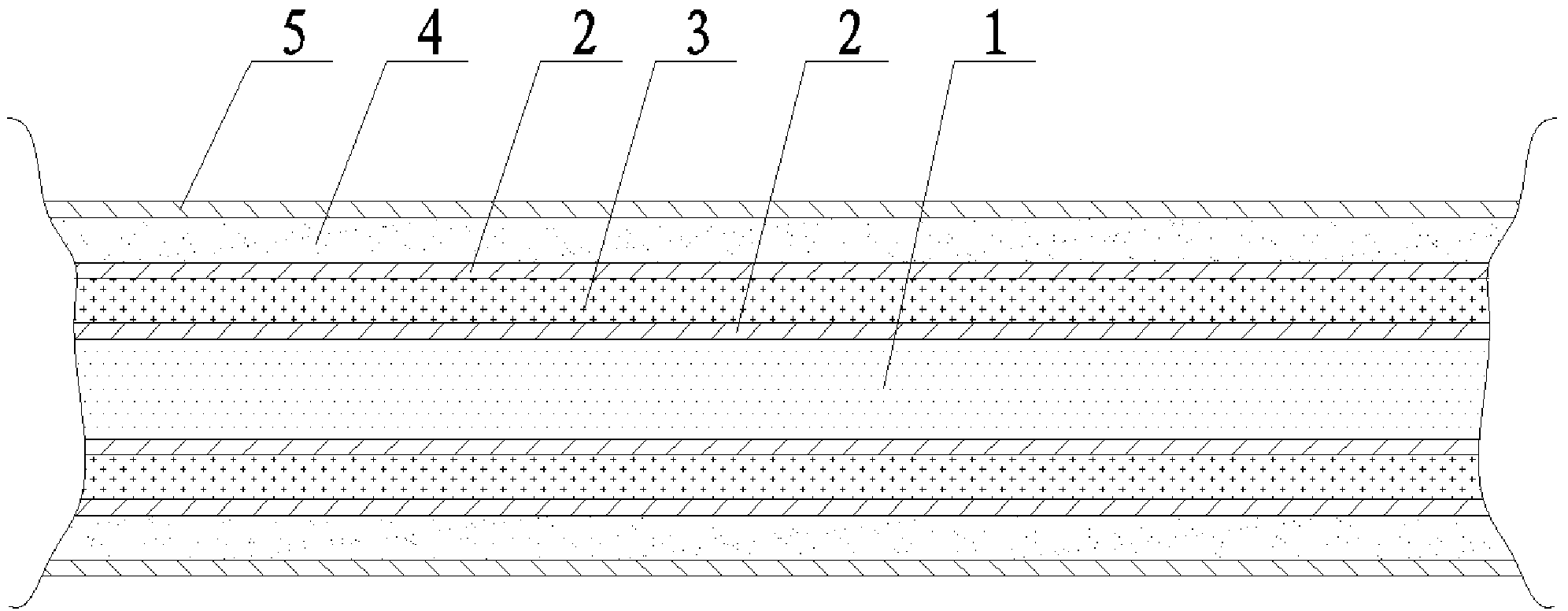

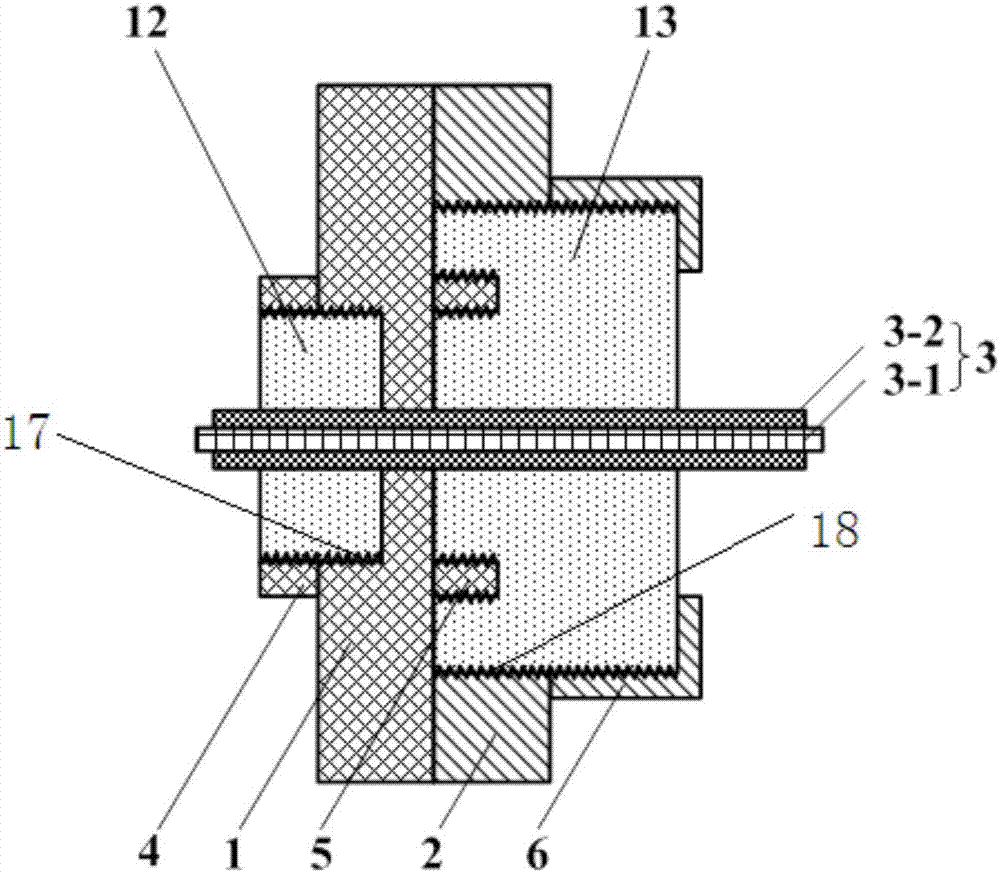

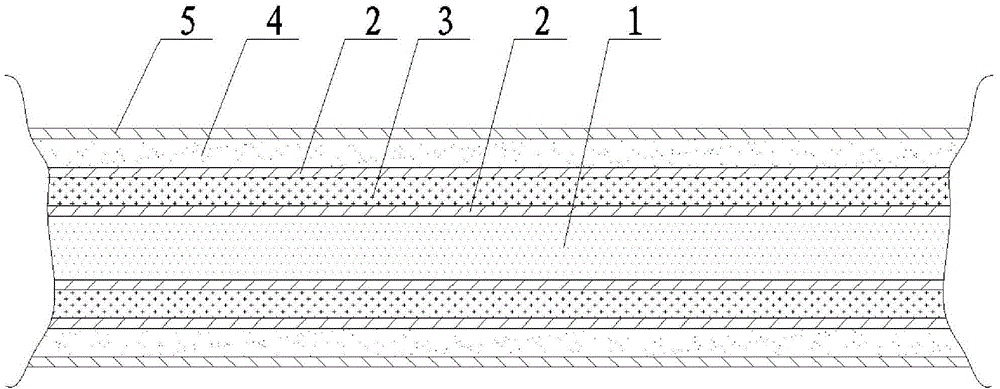

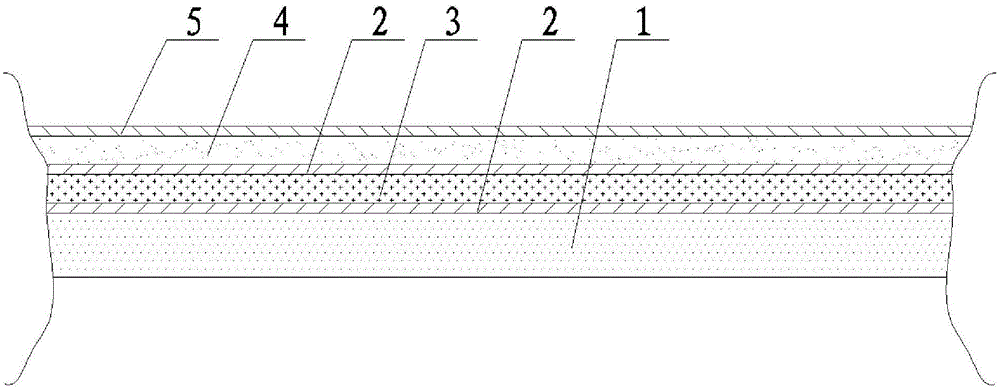

Adhesive tape and display device using same

InactiveCN101768413ADon't worry about damageGuaranteed adhesion strengthFilm/foil adhesivesNon-linear opticsSilicone tapeFiber

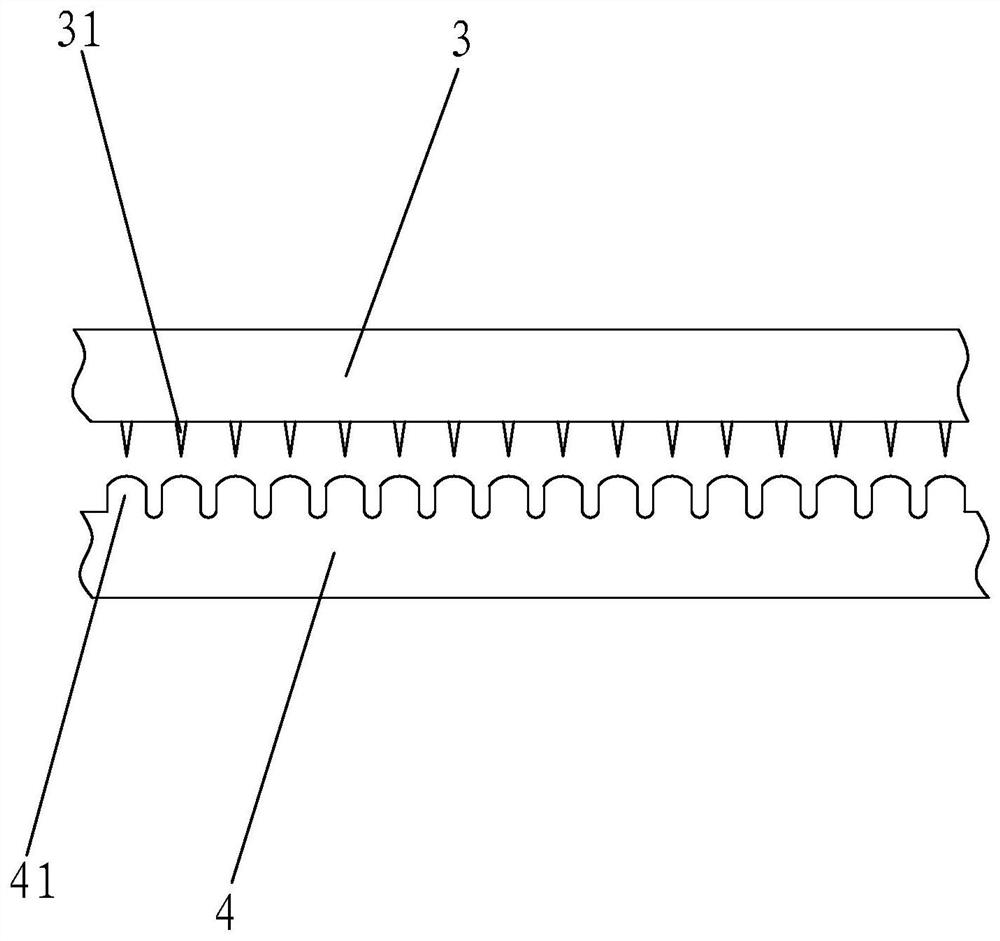

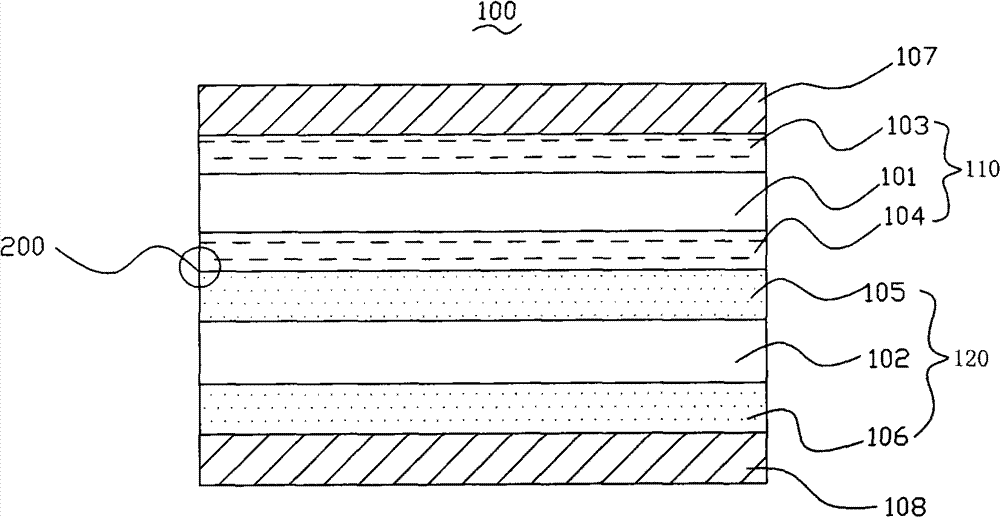

The invention relates to an adhesive tape and a display device using the same. The adhesive tape comprises a first sub-adhesive-tape, a second sub-adhesive-tape and a fiber layer, wherein the first sub-adhesive-tape is provided with a first substrate layer, and a first adhesive layer and a second adhesive layer are arranged between the two sides of the first sub-adhesive-tape; the second sub-adhesive-tape is provided with a second substrate layer, and a third adhesive layer and a fourth adhesive layer are arranged between the two sides of the second sub-adhesive-tape; the third adhesive layeris connected with the second adhesive layer, and the fiber layer is provided with an implantation part and an adhesion part; the implantation part is embedded inside the second adhesive layer, and the adhesion part is wrapped around the surface of the second adhesive layer along a first direction, or the implantation part is embedded inside the third adhesive layer, and the adhesion part is wrapped around the surface of the third adhesive layer along the first direction, so that the resistance generated when the first sub-adhesive-tape is torn relative to the second sub-adhesive-tape along the first direction is less than the resistance generated when the first sub-adhesive-tape is torn relative to the second sub-adhesive-tape along the direction different from the first direction.

Owner:AU OPTRONICS (XIAMEN) CORP +1

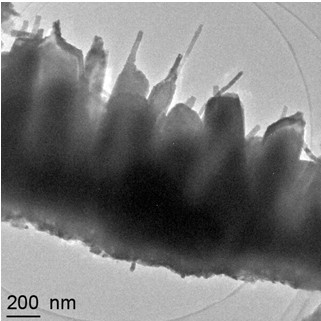

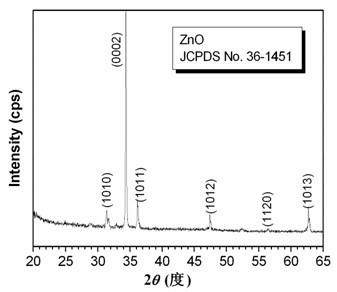

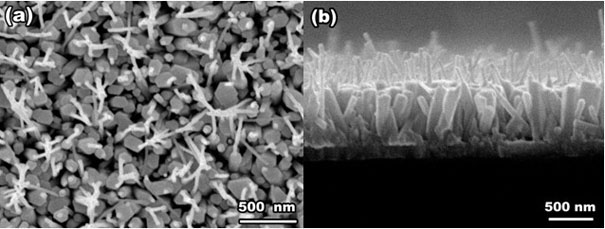

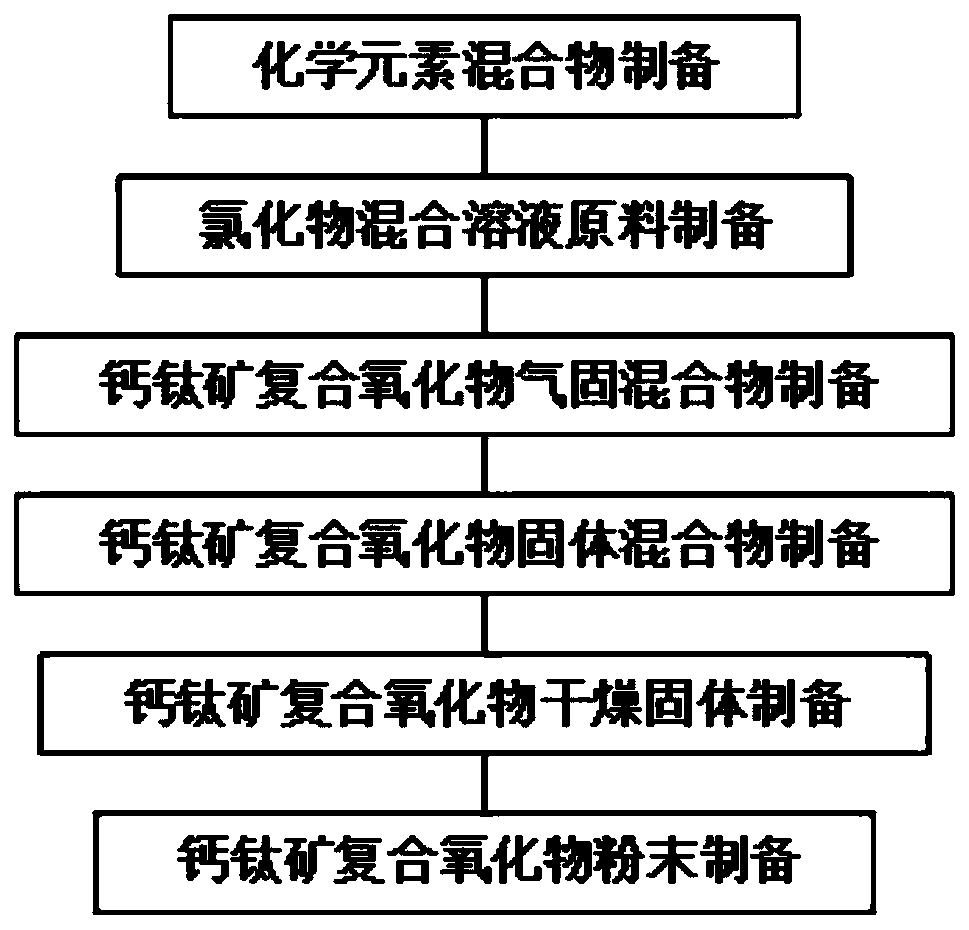

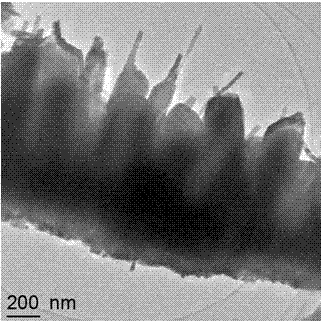

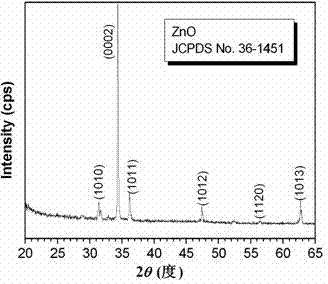

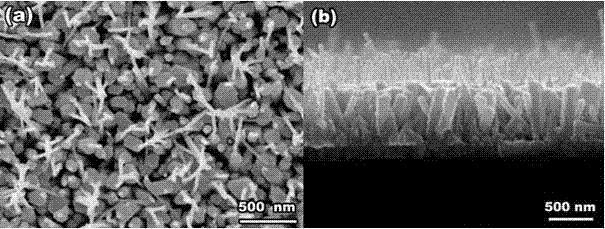

Preparation method of injector-shaped ZnO nanostructural array for field emission

InactiveCN102061498AGuaranteed adhesion strengthFor controlled growthPolycrystalline material growthLiquid-phase epitaxial-layer growthNano structuringNanopillar

The invention relates to a preparation method of an injector-shaped ZnO nano-structural array for field emission, which is a two-step synthesis method based on an aqueous solution system. The method comprises the following steps: firstly, adopting a electrochemical deposition method to directly grow a ZnO nano-column array on a conductive glass substrate; and secondly, adopting the aqueous solution chemical growing method to perform epitaxial growth of nano-needles on the original end surfaces of the ZnO nano-columns. The injector-shaped ZnO nano-structural array is prepared by the two-step synthesis method, thus the adhesive strength of the ZnO nano-structural array on the conductive substrate can be ensured, the electrical conductivity can be increased, the controllable growth of the pointed nanostructure, which is beneficial for electron emission can be realized and the field emission performance of the array structure can be improved.

Owner:SOUTHEAST UNIV

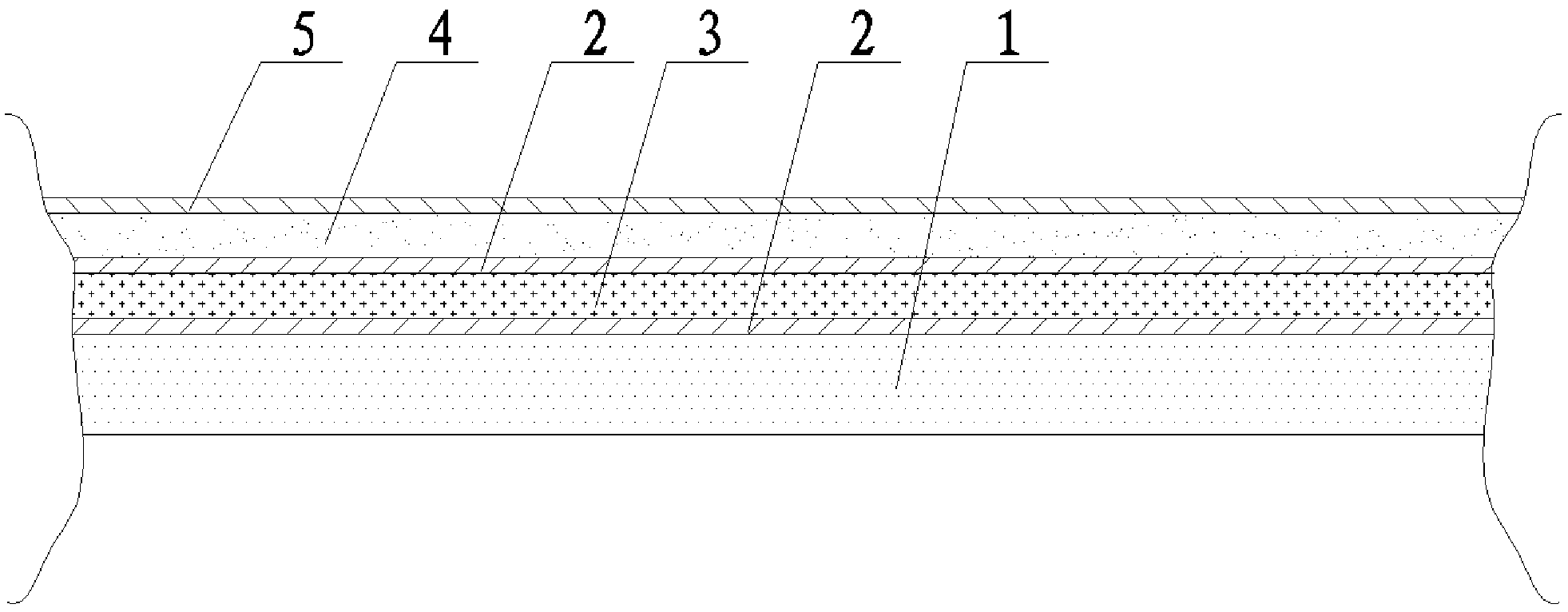

High temperature fire-proof synthetic crystal insulating tape and production process thereof

InactiveCN103325505AImprove moisture resistanceGuaranteed uniformityInsulated cablesInsulating bodiesEpoxyPolyester

The invention discloses high temperature fire-proof synthetic crystal insulating tape. The high temperature fire-proof synthetic crystal insulating tape has a damp-proof property, and further has a high temperature resistant inflaming retarding property. The invention further discloses the process for producing the crystal insulating tape. The high temperature fire-proof synthetic crystal insulating tape is single face synthetic mica tape comprising a six-layer structure or a double-face synthetic mica tape comprising an eleven-layer structure, and the six-layer single face synthetic mica tape comprises a fire retardant layer, a polyester film, a viscose layer, alkali-free glass cloth, a viscose layer, synthetic mica paper, a viscose layer, alkali-free glass cloth, a viscose layer, a polyester film and a fire retardant layer from top to bottom. Each viscose layer adopts organic silicon resin or epoxy resin adhesive, and each fire retardant layer adopts phosphorus-nitrogen fire retardant. The invention further discloses the production process of the high temperature fire-proof synthetic crystal insulating tape.

Owner:常州欧贝斯绝缘材料有限公司

Surface treatment process for aluminum alloy sections for doors and windows

The invention provides a surface treatment process for aluminum alloy sections for doors and windows. The surface treatment process comprises the following steps: a, removing oil; b, drawing; c, chemical polishing; d, performing anodic oxidation; and e, performing anticorrosive protection. According to the aluminum alloy sections treated by the surface treatment process for aluminum alloy sections for doors and windows disclosed by the invention, the surface has high hardness and strength and bright color, and the aluminum alloy section can be kept for a long time.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

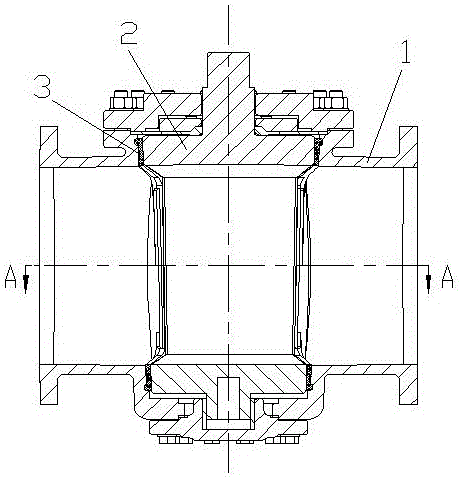

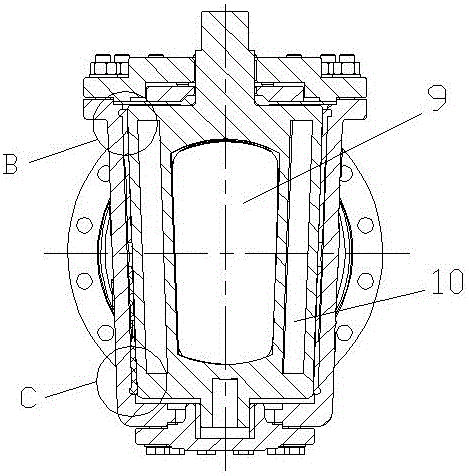

Soft-sealing cock valve

InactiveCN106641323AAvoid displacementAffects adhesion strengthPlug valvesInterference fitEngineering

The invention provides a soft-sealing cock valve which can effectively prevent a bushing from shifting. The soft-sealing cock valve comprises a valve body, a cock and the bushing; a flow channel hole is formed in the valve body, and the cock is installed in the valve body and used for opening and closing the flow channel hole; the bushing is fixed to the hole wall of the flow channel hole; a bushing hole is formed in the bushing, the cock is pressed into the bushing hole, and the cock is in interference fit with the bushing; an upper groove and a lower groove are formed in the valve body, the bushing is fixedly provided with an upper fixing block and a lower fixing block, the upper fixing block is inlaid into the upper groove to be fixed, the lower fixing block is inlaid into the lower groove to be fixed, and after the upper groove is matched with the upper fixing block and the lower groove is matched with the lower fixing block, the bushing is constrained in the axial direction of the cock; anti-rotating ribs are fixed to the hole wall of the flow channal hole, located on the two sides of the bushing and matched with the bushing and constrains the bushing in the rotating direction of the cock; the flow channel hole is a tapered hole.

Owner:HANGZHOU ANQILA TECH

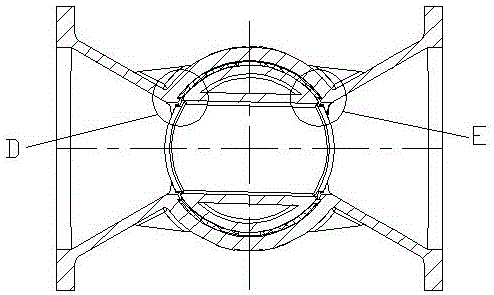

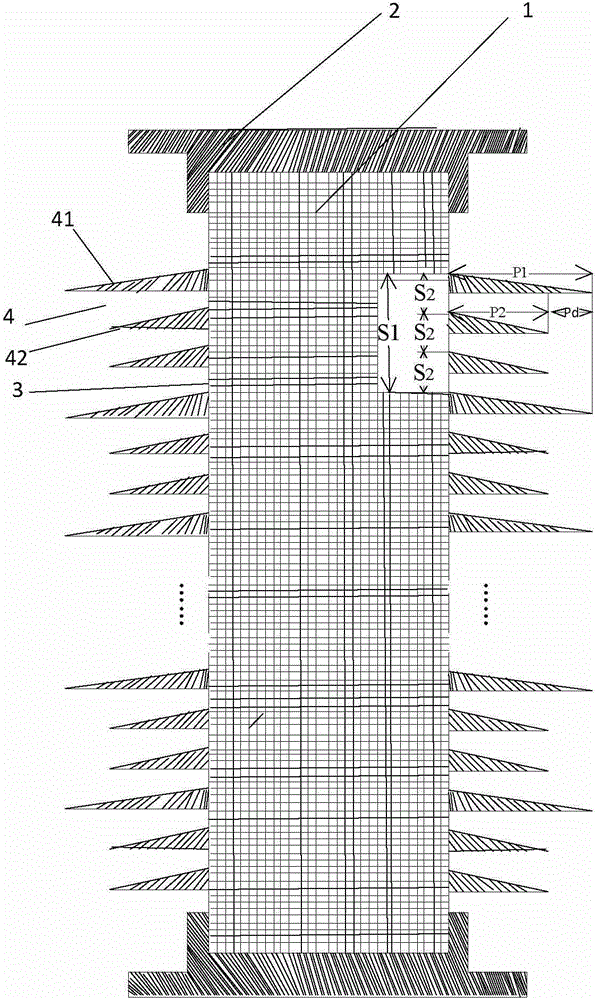

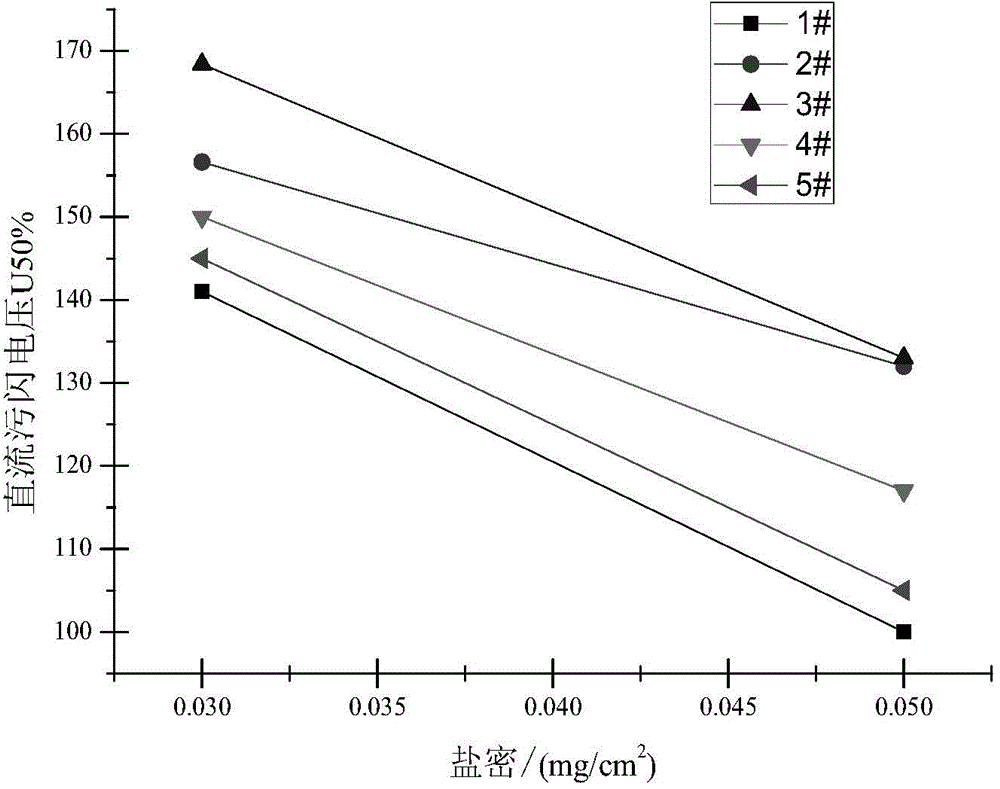

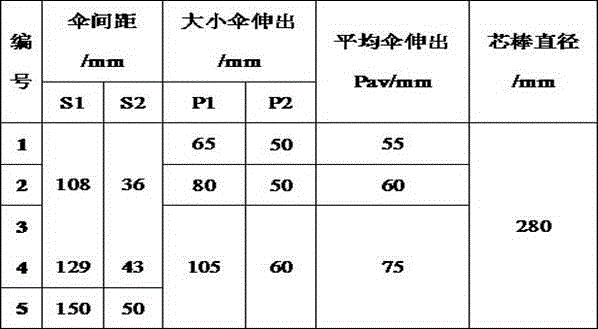

One-large two-small umbrella-shaped DC composite post insulator used for high altitude area

InactiveCN104835604ASimple structureImprove reliabilitySuspension/strain insulatorsEngineeringSilicon

The invention discloses a one-large two-small umbrella-shaped DC composite post insulator used for high altitude areas. The composite post insulator is formed by a glass core rod, an outer umbrella cover, and end metal flanges, wherein the core rod is provided with a silicone rubber sheath. The silicone rubber sheath is uniformly provided with silicone rubber umbrella skirts. The umbrella skirts are formed by arranging a plurality of large umbrella skirts which are equal in diameters, and two small umbrella skirts between each two adjacent large umbrella skirts. The distance between the adjacent large umbrella skirts is 90-180 mm. Average umbrella extension of an umbrella skirt unit is 55-90 mm. The extension difference of large umbrella skirt and small umbrella skirt is 20-60 mm. Through cooperative effect of the umbrella extension of the large umbrella skirts and small umbrella skirts, umbrella distances, and other parameters, umbrella skirt structural parameters of the composite post insulator whose DC flashover performance is optimal are obtained, so that the composite post insulator has excellent stain-resistant wet-flashover performance under the condition of the same structure height, and consumption of umbrella skirt materials of the insulator is greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

Rubber double-sealing structure for underwater motor cable

PendingCN107070064AImprove adhesion strengthGuaranteed adhesion strengthSupports/enclosures/casingsClimate change adaptationMotor end platesEngineering

The invention provides a rubber double-sealing structure for an underwater motor cable, which comprises a motor end plate with a round groove and a guide pipe wall plate with a round through hole, wherein the motor end plate and the guide pipe wall plate are tightly matched; the groove center of the motor end plate is provided with a round cable passing hole; a vulcanized boss extends from the groove cutting end of the motor end plate and a first watertight cavity is formed with the groove of the motor end plate; a vulcanized end cover extends from the hole opening place of the guide pipe wall plate; the end cover has an L-shaped cross section; the vulcanized end cover, the round hole in the guide pipe wall plate and the motor end plate form a second watertight cavity; an enhanced boss fixed on the back surface of the motor end plate for isolating sea water is embedded in the second watertight cavity; inner thread is processed in the first watertight cavity and the second watertight cavity along the axial direction; and inner thread and outer thread are processed on the inner surface and the outer surface of the enhanced boss respectively along the axial direction.

Owner:NAVAL UNIV OF ENG PLA

Aluminum material with dye on surface

InactiveCN109853020AImprove bindingExtension of timeAnodisationPretreated surfacesElectrolysisVolumetric Mass Density

The invention relates to an aluminum material with dye on the surface and belongs to the technical field of civil functional aluminum material processing. A preparation method of the aluminum materialwith the dye on the surface comprises the steps that an aluminum part serves as an anode to be immersed in an electrolyte with the nitric acid content being 45-55wt%, under the conditions that the current density is 2400-2600 A / m<2>, the working voltage is 13.5-16.5 V, and the electrolytic temperature is 21-27 DEG C, electrolytic oxidation is conducted for 20-25 min, and thus a layer of anodic oxide film is obtained on the surface of the aluminum part; then the aluminum part subjected to anodic oxidation is immersed into coloring liquid for dye coloring; the colored aluminum part is immersedinto a hole sealing solution for hole sealing; and the aluminum part subjected to hole sealing is placed in a spraying chamber, mixed coating is sprayed in the electrostatic environment and under thecondition of 100,000 grades or above of dust prevention, a 20-35 [mu]m of functional coating layer is formed on the surface of the aluminum part, and finally, a finished product is obtained through curing.

Owner:QIYANG HONGTAI ALUMINUM IND

Imitated stainless steel aluminum surface treatment technology

ActiveCN102925948BBright colorFresh Time GuaranteedSurface reaction electrolytic coatingPretreated surfacesHardnessAnode oxidation

The invention discloses an imitated stainless steel aluminum surface treatment technology, relating to the technical field of aluminum surface treatment. The technological flow comprises the following steps of: (1) surface pretreatment: A, oil removal; B, dirt removal; C, anode oxidation; D, coloring; and E, primary hole sealing; (2) surface re-treatment: F, spraying of a mixed coating; and G, curing. The surface of the aluminum product after the treatment has relatively high hardness and strength as well as the characteristics of bright color, long maintaining time and the like; and the technology is suitable for treating panels and sections made from aluminum products and having various colors.

Owner:QIYANG HONGTAI ALUMINUM IND

Textile sizing agent applied to textile industry and preparation method of textile sizing agent

InactiveCN104818619AHeat and mix wellGuarantee soft and hard comfortFibre treatmentPolymer scienceAdhesive

The invention discloses a textile sizing agent applied to a textile industry. The textile sizing agent comprises the following components in parts by weight: 100 parts of starch, 0.2-0.4 part of ferrous sulfate, 5-8 parts of sodium borate, 2-5 parts of sodium hypochlorite, 4-5 parts of lignosulfonate, 18-23 parts of montmorillonite, 0.05-0.1 part of tributyl phosphate, 0.7-2.5 parts of uniconazole, 2-6 parts of fumed silica, 25-29 parts of 40% sodium hydroxide solution and 100-200 parts of water. Compared with an existing starch adhesive, the natural adhesive disclosed by the invention has the advantages that through interaction of unique lignosulfonate and uniconazole, montmorillonite, fumed silica and other components, the adhesive strength is ensured; the line generated by the sizing agent is moderate in hardness and comfortable; and the breakage rate is greatly reduced.

Owner:陈素素

High-strength steel strand manufacturing and processing equipment and processing technology

InactiveCN113389074AImprove adhesionImprove strong adhesionPretreated surfacesRope making machinesStress reliefMachining process

The invention relates to high-strength steel strand manufacturing and processing equipment and a processing technology. The equipment comprises two traction guiding devices used for guiding in and guiding out of a steel strand, a coating device, a wind finishing and drying device and three series connection frames. According to the equipment provided by the invention, automatic coating and automatic drying shaping can be directly carried out on the steel strand which is subjected to stranding shaping and stress relief, rolling packaging can be carried out immediately after shaping, and the equipment can adapt to the whole streamlined manufacturing and processing process of the steel strand; and compared with an existing spraying mode which widely adopts electrostatic spraying, the equipment provided by the invention has the outstanding advantages of simple structure, convenience in assembly, low equipment cost, no risk in operation, strong coating adhesive force, uniform and smooth coating and the like, and the problems that an existing electrostatic spraying processing mode is poor in coating distribution uniformity, high in operation risk and high in equipment cost input are solved.

Owner:湖北炫盛鸿吉科技有限公司

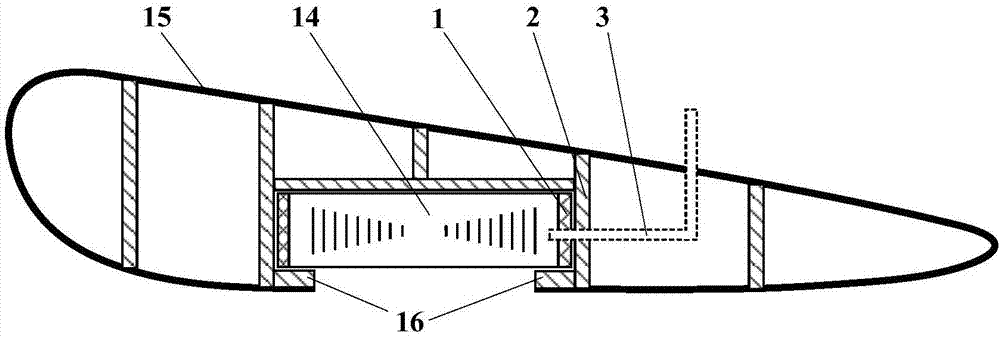

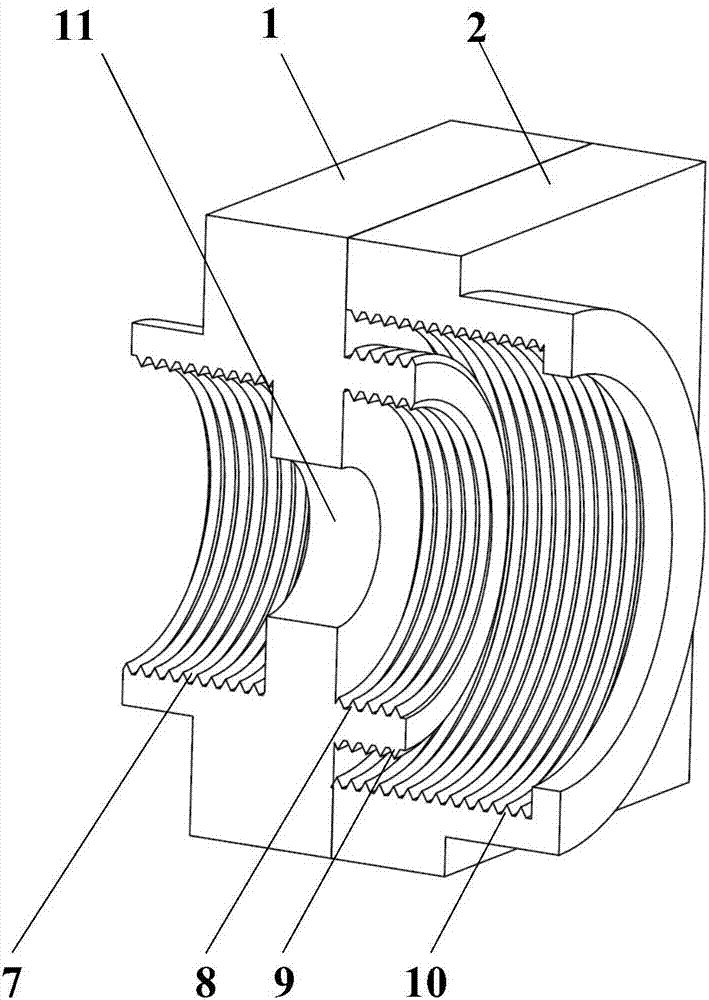

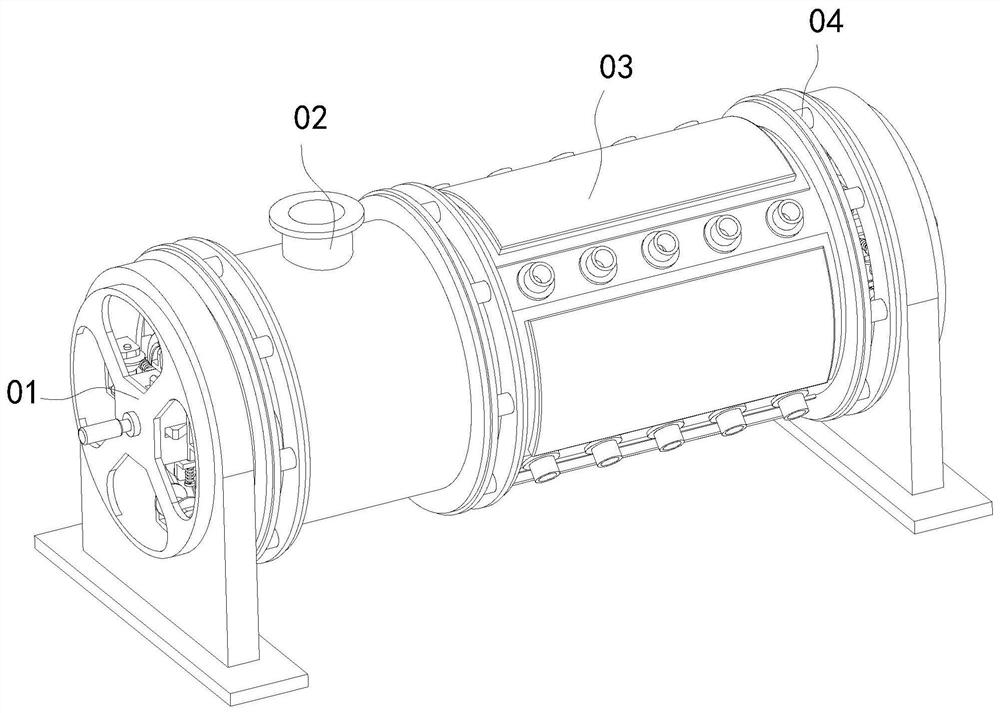

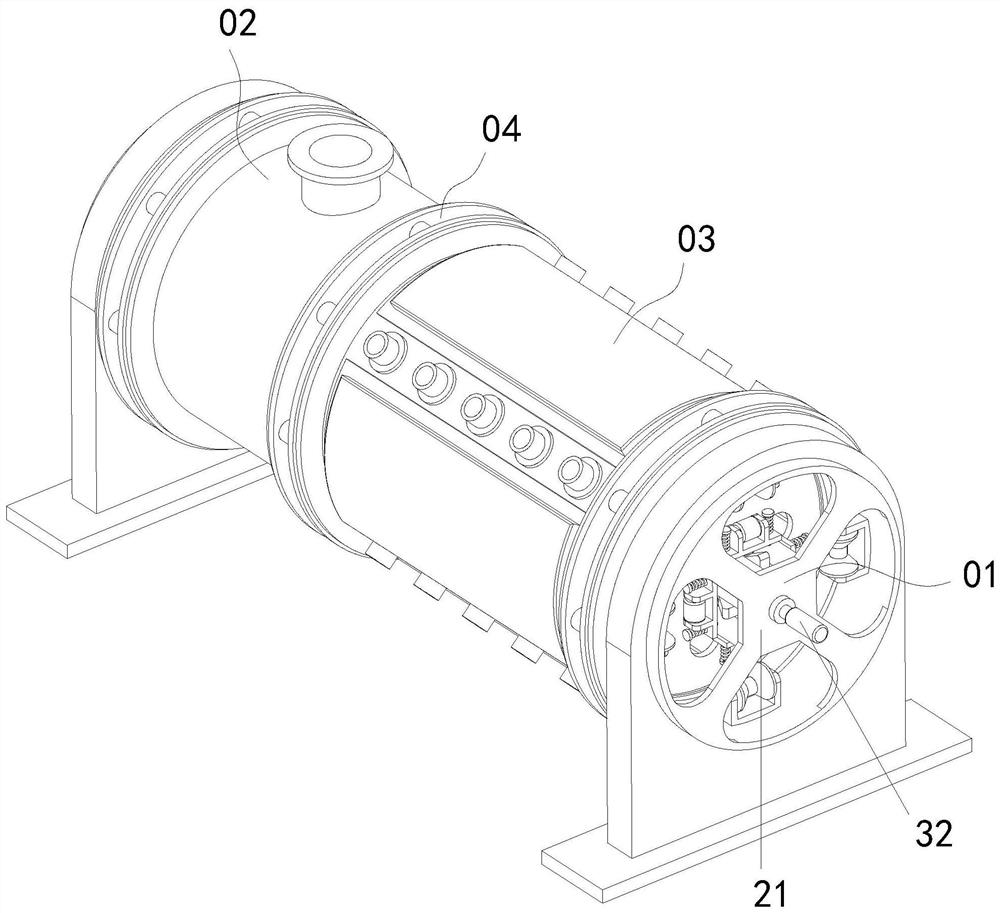

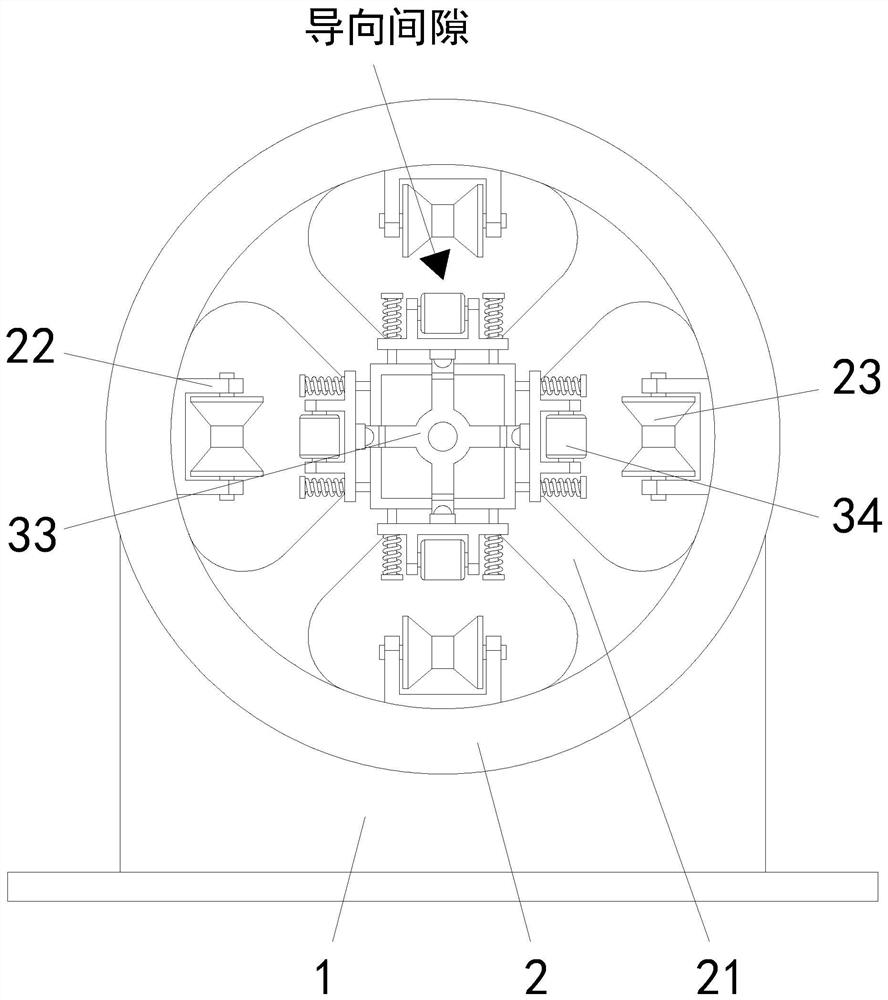

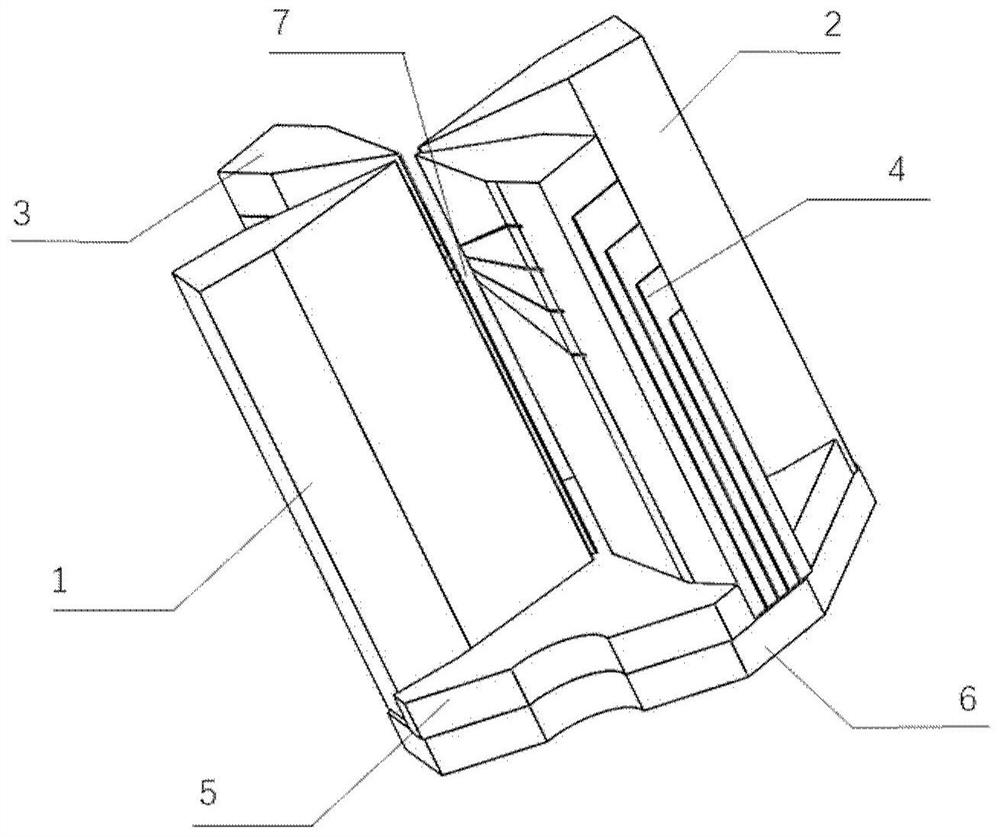

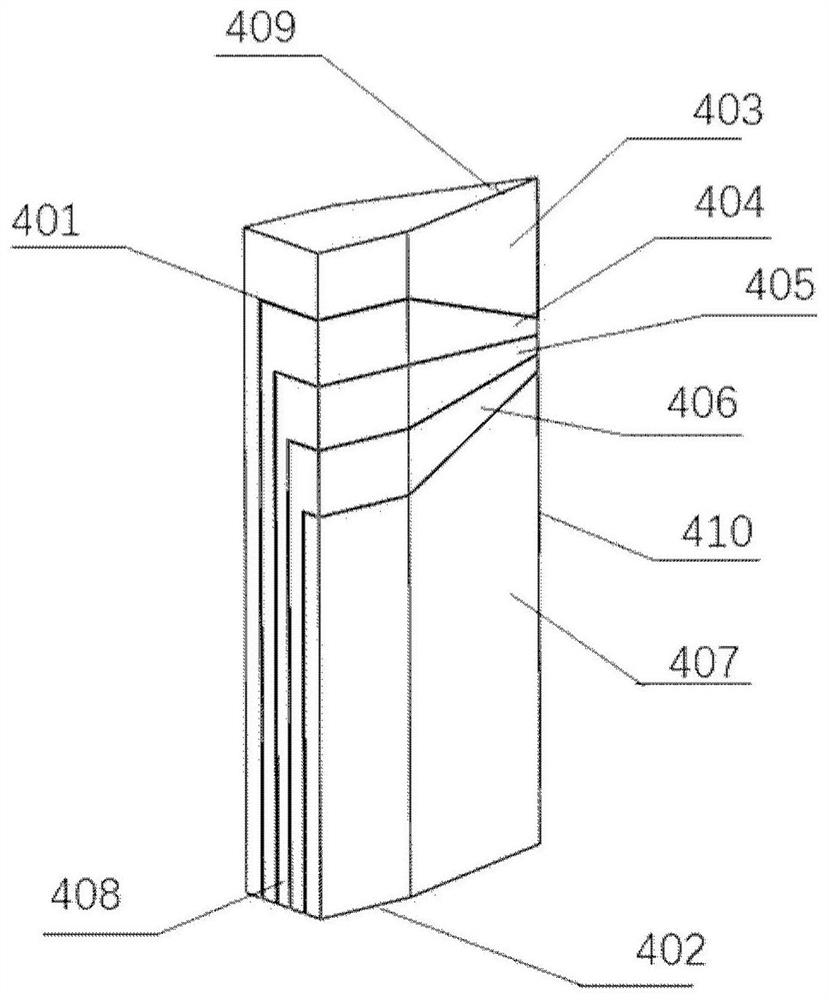

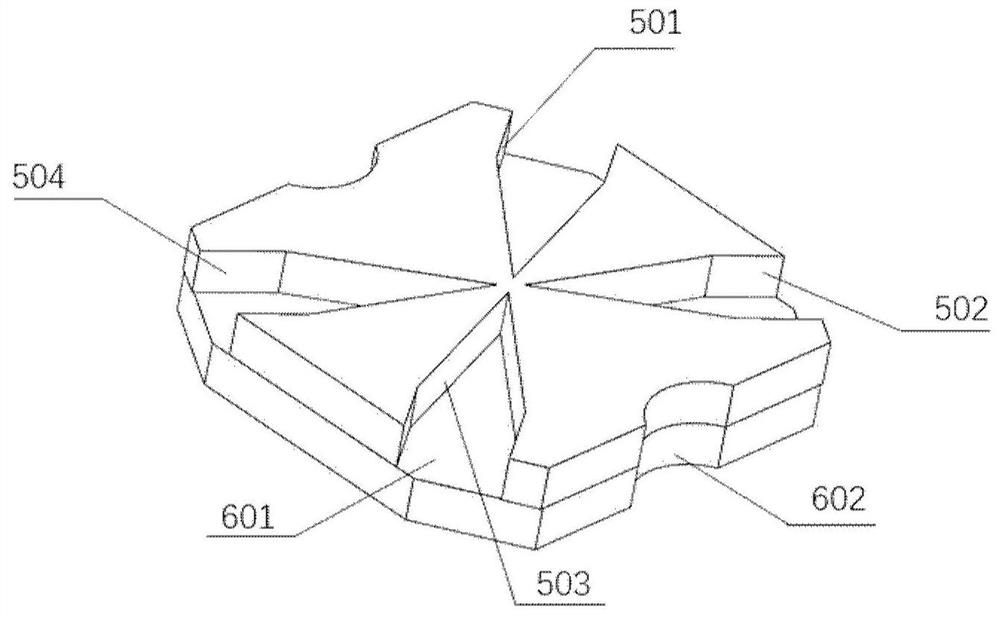

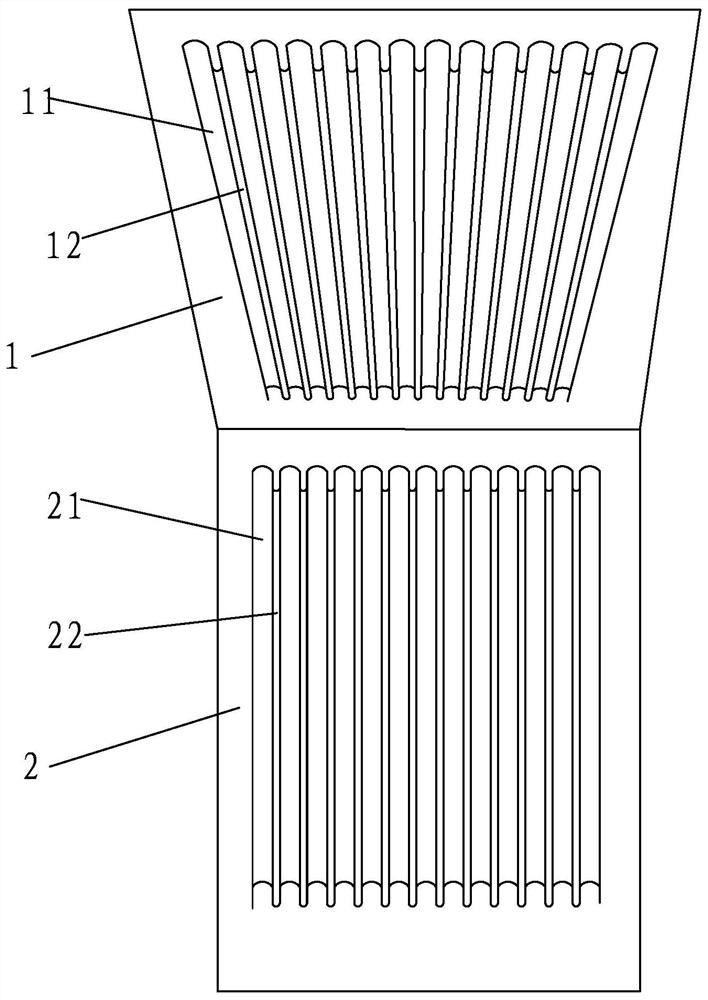

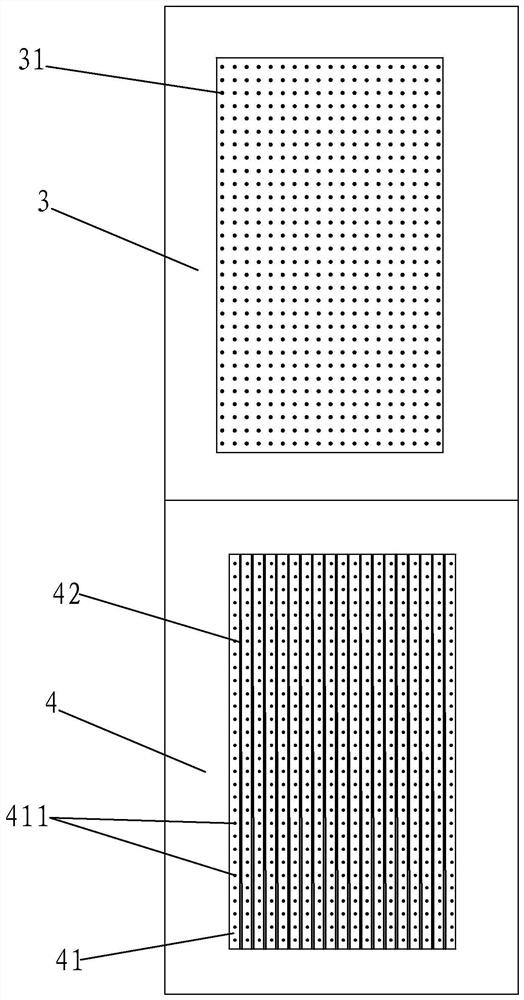

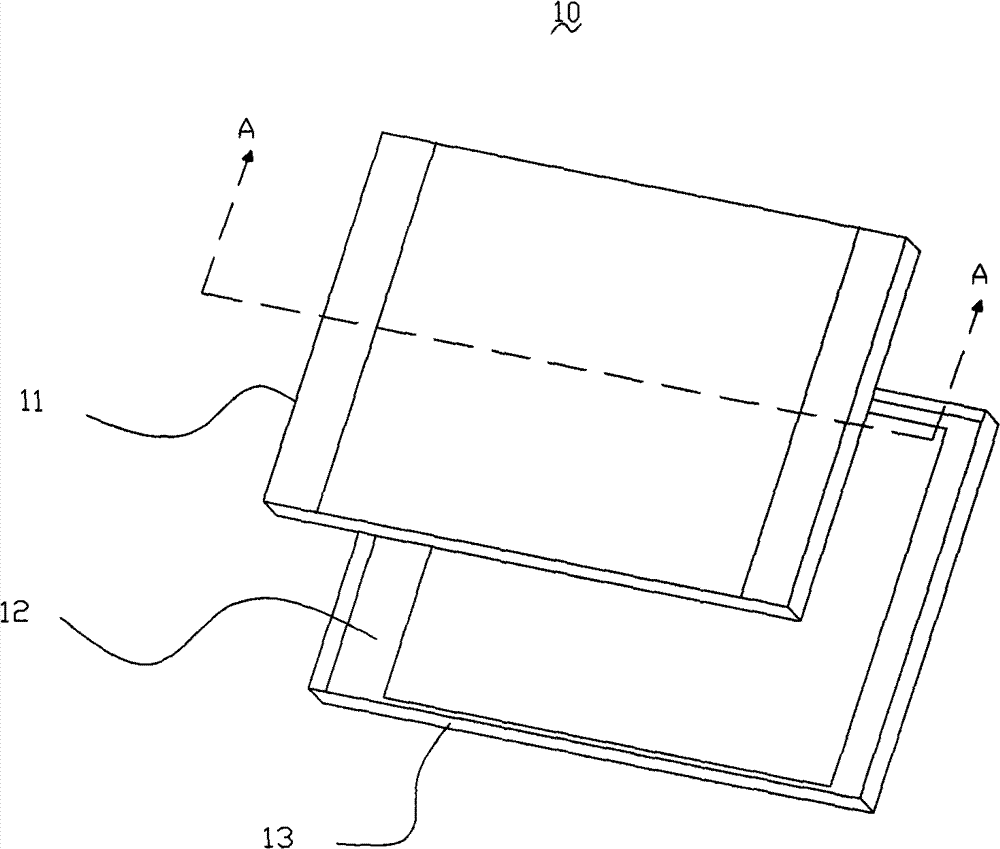

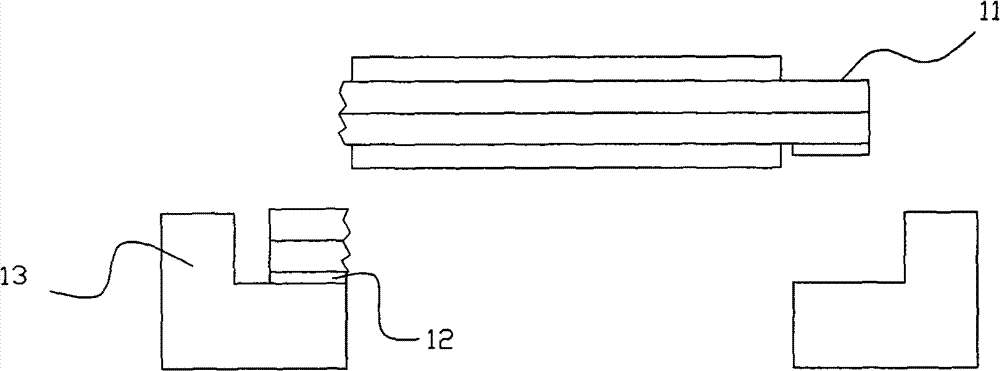

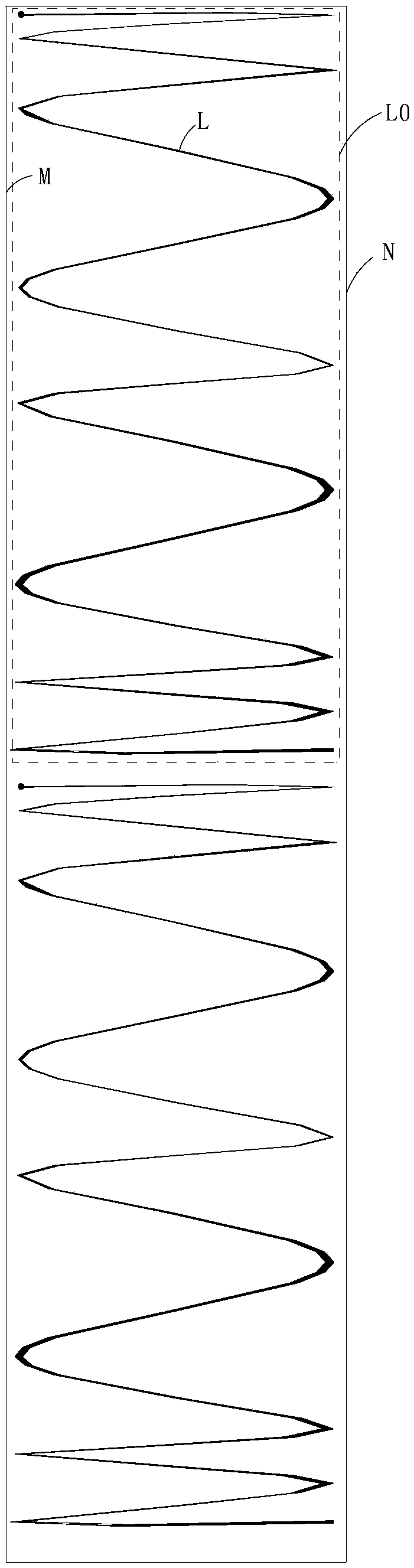

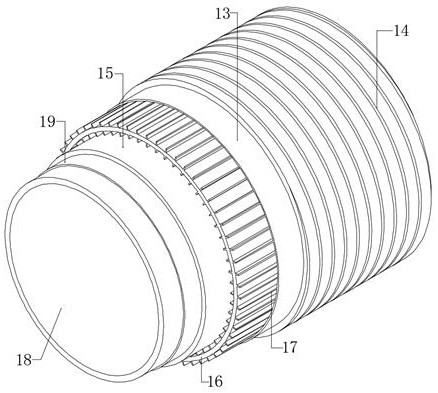

A segmented blade ion trap device

ActiveCN111128672BEasy to installImprove assembly accuracyStability-of-path spectrometersRadiation/particle handlingIon trap mass spectrometryEngineering

A segmented blade ion trap device, the device includes a first radio frequency electrode, a second radio frequency electrode, a first direct current electrode, a second direct current electrode, an upper fixed substrate and a lower fixed substrate, wherein the first radio frequency electrode and the second The radio frequency electrode is used to provide a radio frequency electric field; the first direct current electrode and the second direct current electrode are used to provide an axial confinement electric field and compensate for the micro-movement of ions; Assembly and fixation of electrodes, first DC electrodes, and second DC electrodes. The segmented blade ion trap device provided by the present invention realizes the assembly and fixing of the first radio frequency electrode, the second radio frequency electrode, the first DC electrode and the second DC electrode based on the upper fixed substrate and the lower fixed substrate, the upper fixed substrate and the lower fixed substrate The method of chemical bonding is adopted between the fixed substrates, which is convenient for installation, reduces the difficulty of assembly, has high assembly precision, is convenient for component replacement, and reduces the complexity of the system.

Owner:合肥幺正量子科技有限公司

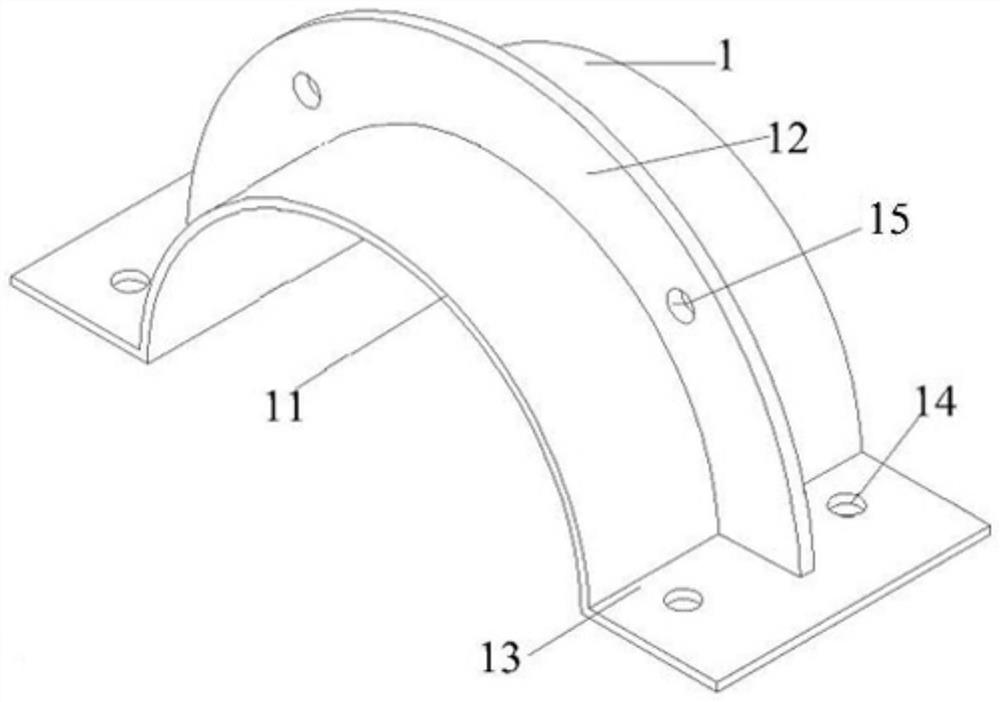

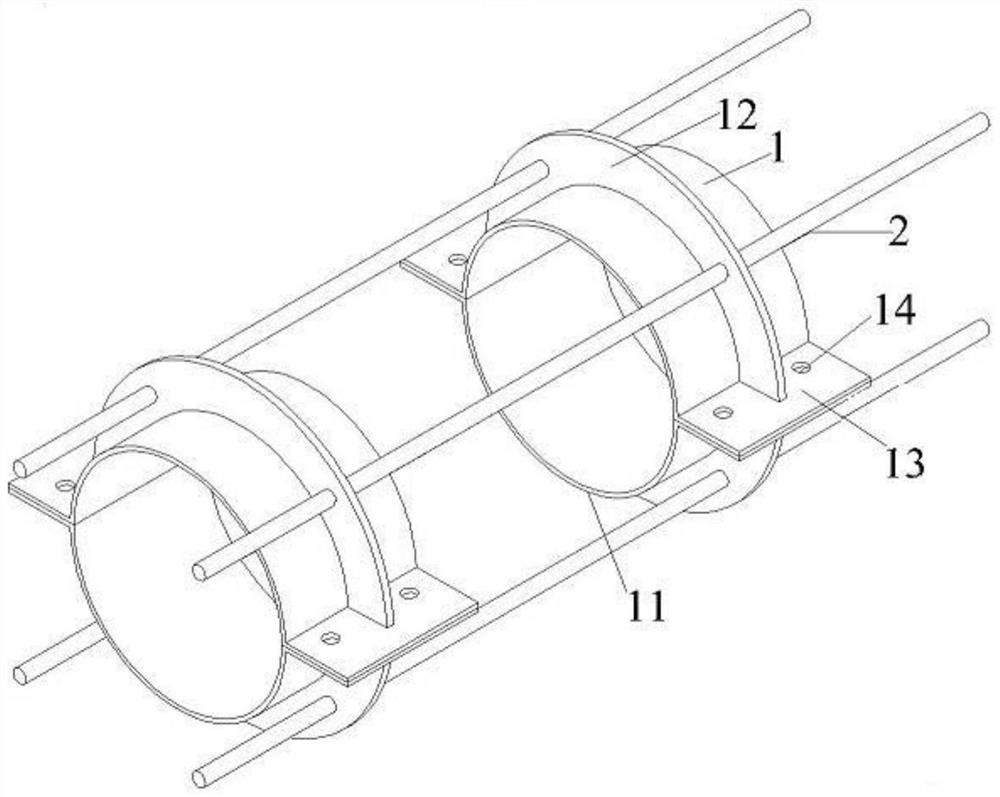

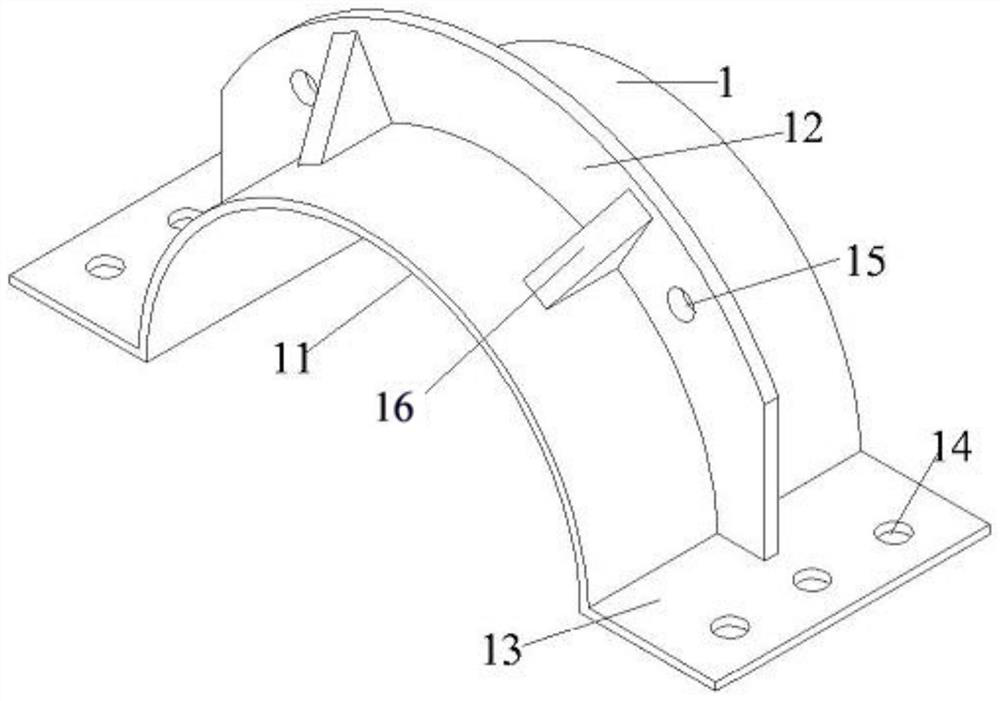

PE electric smelting sleeve protection device and installation method

PendingCN113639139AAchieve protectionGuaranteed adhesion strengthPipe elementsPipe connection arrangementsMechanical engineeringPipe welding

The invention relates to a PE electric smelting sleeve protection device and an installation method, and belongs to the technical field of fuel gas conveying. The PE electric smelting sleeve protection device is used for protecting a PE electric smelting sleeve from distortion and deformation due to the influence of external force and ensuring safe fuel gas conveying. The PE electric smelting sleeve protection device comprises at least two sets of detachable protection device assemblies, and the protection device assemblies are of annular cylindrical structures and fixedly arranged on PE pipelines at the two ends of a PE electric smelting sleeve in a sleeving mode through metal screws and fixing bolts. According to the PE electric smelting sleeve protection device, under the conditions of sedimentation and external digging force, especially in foundation soft environments such as pit filling and water filling, the external force borne by the PE electric smelting sleeve protection device can be dispersed to PE pipelines at the two ends of the PE electric smelting sleeve, the PE electric smelting sleeve is effectively protected to be in the state that the PE electric smelting sleeve is not subjected to external stress or is subjected to less external stress, the bonding strength of the welding position of the PE electric smelting sleeve and the PE pipelines is guaranteed, the air leakage problems of distortion, deformation and the like caused by sedimentation and external force of the PE electric smelting sleeve are solved, and the PE pipelines are protected.

Owner:青岛泰能高新燃气有限公司

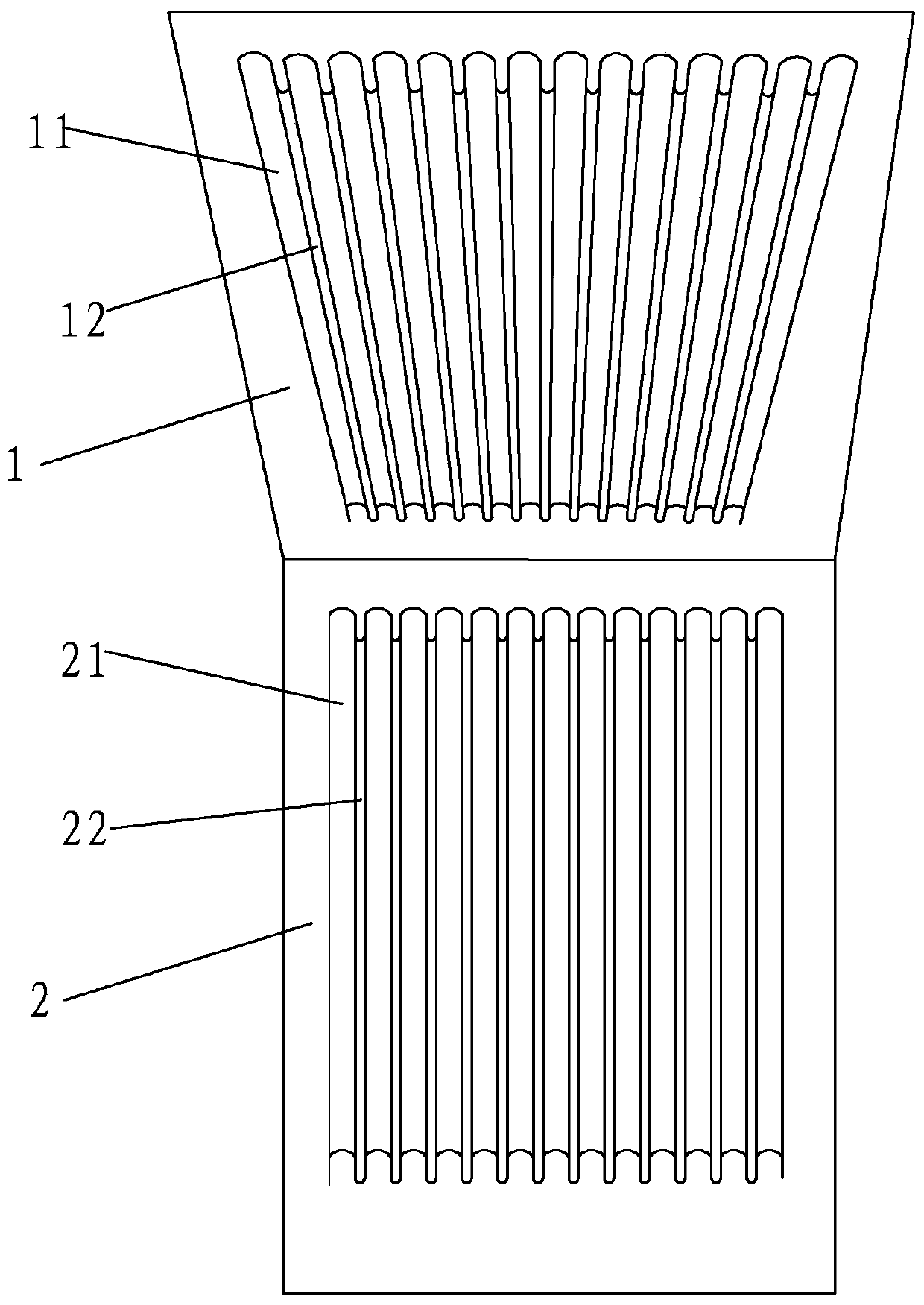

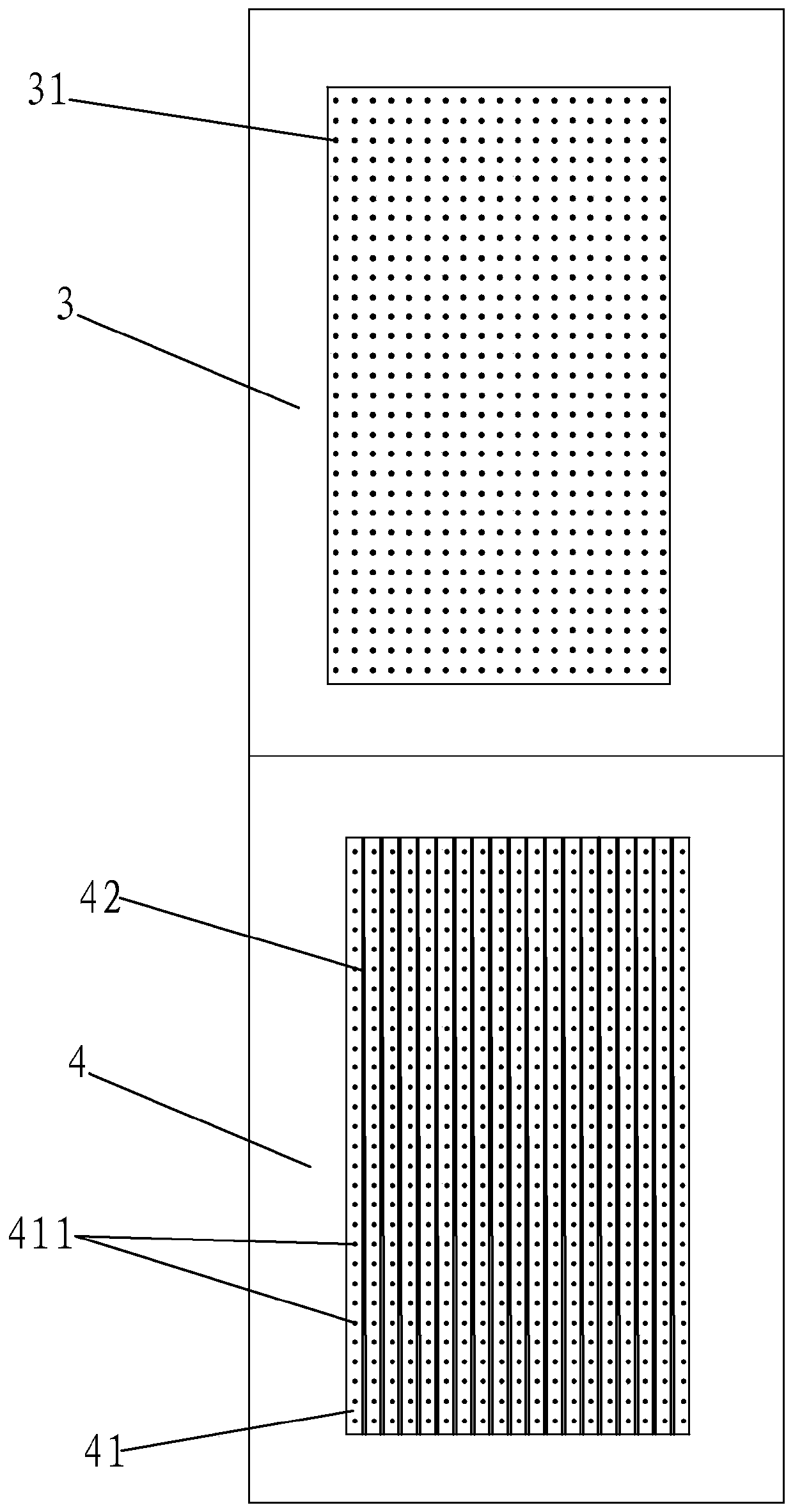

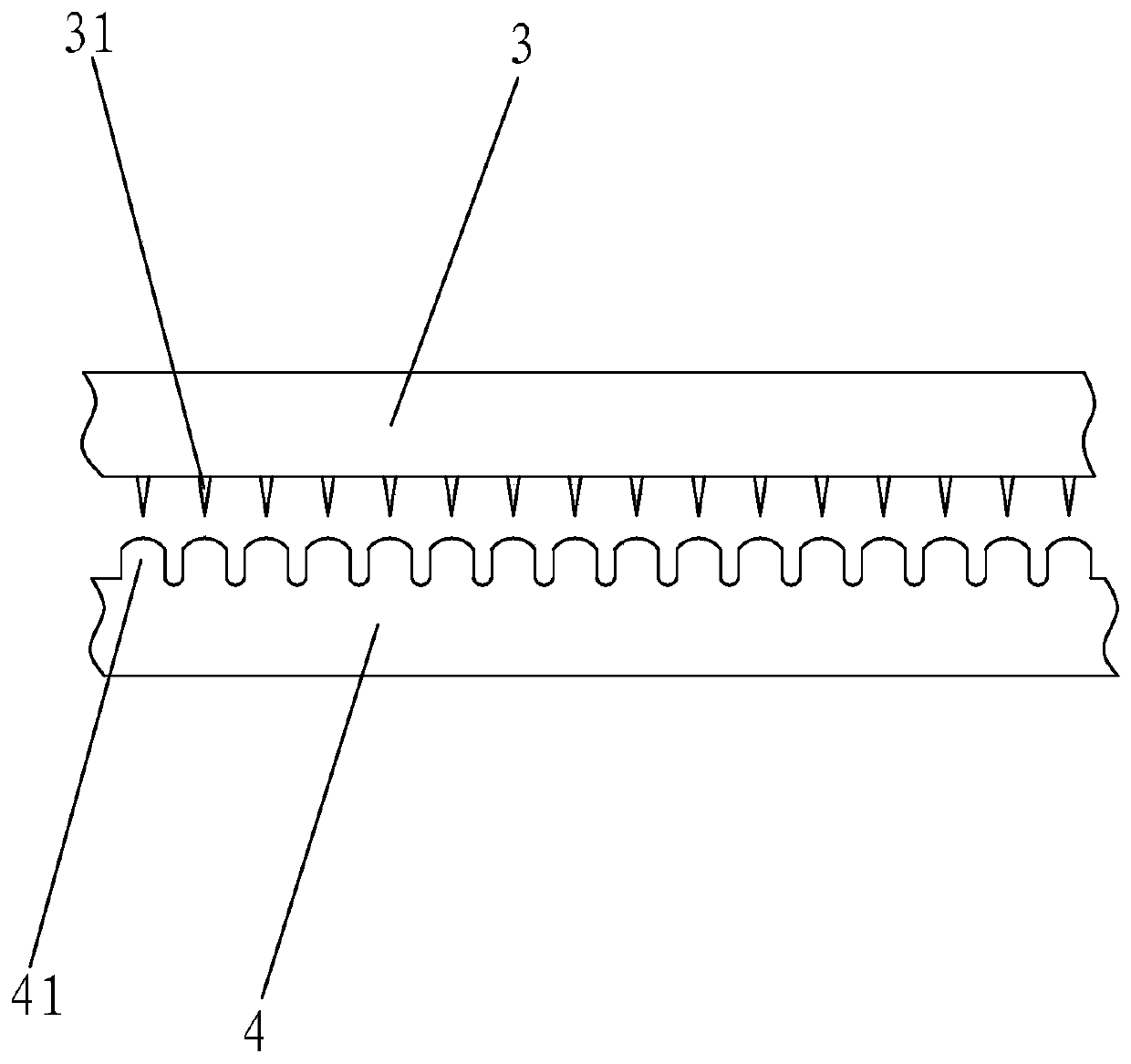

A processing method of ventilated Gangbao hot-melt film forming mold

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

Adhesive tape and display device using same

InactiveCN101768413BDon't worry about damageGuaranteed adhesion strengthFilm/foil adhesivesNon-linear opticsDisplay deviceEngineering

The invention relates to an adhesive tape and a display device using the same. The adhesive tape comprises a first sub-adhesive-tape, a second sub-adhesive-tape and a fiber layer, wherein the first sub-adhesive-tape is provided with a first substrate layer, and a first adhesive layer and a second adhesive layer are arranged between the two sides of the first sub-adhesive-tape; the second sub-adhesive-tape is provided with a second substrate layer, and a third adhesive layer and a fourth adhesive layer are arranged between the two sides of the second sub-adhesive-tape; the third adhesive layeris connected with the second adhesive layer, and the fiber layer is provided with an implantation part and an adhesion part; the implantation part is embedded inside the second adhesive layer, and the adhesion part is wrapped around the surface of the second adhesive layer along a first direction, or the implantation part is embedded inside the third adhesive layer, and the adhesion part is wrapped around the surface of the third adhesive layer along the first direction, so that the resistance generated when the first sub-adhesive-tape is torn relative to the second sub-adhesive-tape along the first direction is less than the resistance generated when the first sub-adhesive-tape is torn relative to the second sub-adhesive-tape along the direction different from the first direction.

Owner:AU OPTRONICS (XIAMEN) CORP +1

Helicopter aluminum alloy casing outer hoop cementing method

InactiveCN108000887AGuaranteed reliabilityGuaranteed adhesion strengthDomestic articlesCleaning using liquidsSand blastingShape optimization

The invention relates to a helicopter aluminum alloy casing outer hoop cementing method. Through carrying out sand blasting processing on a cemented surface, simultaneously combining protecting and cleaning steps, gelatinizing, fastening, solidifying, and coating a sealant, the reliability in cementing is ensured; through determining the conditions for optimizing an outer hoop shape, testing the strength of a cementing compound, and solidifying, aluminum alloy parts on an engine are not cracked at cemented parts under the conditions of continuous vibrating at the high temperature of more than120 DEG C, are stable and reliable in cementing quality, and meet the working requirement of the parts under a special working condition.

Owner:HARBIN DONGAN ENGINE GRP

Preparation method of bimetal glued composite tube

InactiveCN111716745AGuaranteed pass rateGuaranteed adhesive strengthTubular articlesAdhesiveManufacturing engineering

The invention discloses a preparation method of a bimetal glued composite tube. The preparation method comprises the following steps that S1, decontamination and rust removal treatment is conducted onthe outer surface of a liner tube and the inner surface of a base tube; S2, an adhesive is coated on the outer surface of the liner tube or the inner surface of the base tube or the outer surface ofthe liner tube and the inner surface of the base tube; S3, the liner tube is nested into the base tube and is subjected to pressurizing to enable the base tube, the adhesive and the liner tube to be tightly attached together to form the composite tube; S4, the end of the liner tube of the composite tube and the adhesive at the end of the liner tube are removed, and the adhesive with the depth of 10mm-30 mm between the remaining liner tube and the base tube is removed; S5, the end of the composite pipe is subjected to surfacing treatment, so that the liner tube is connected with the base tube;and S6, the composite pipe is heated. According to the prepared composite tube, the adhesive force strength of the adhesive is good, and the product preparation qualification rate is high.

Owner:ZHEJIANG JIULI HI TECH METALS

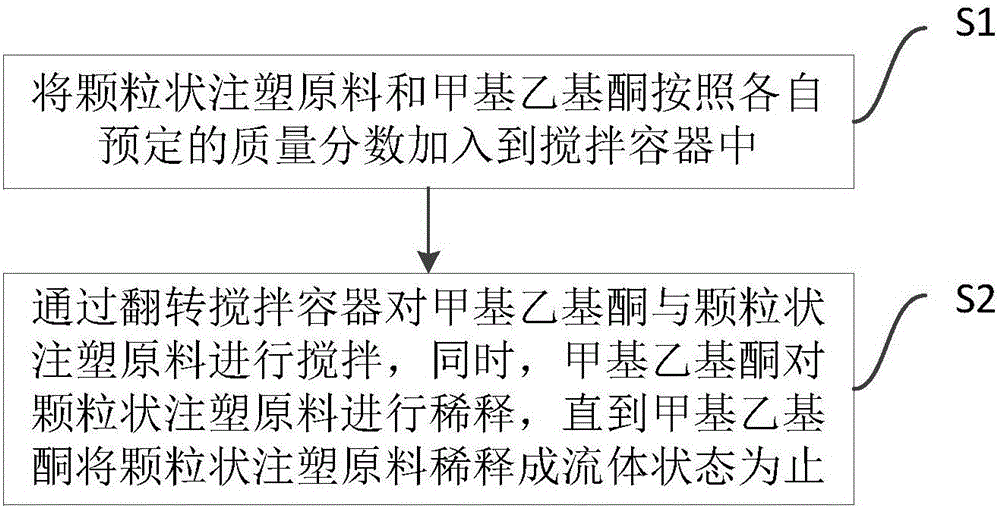

Self-prepared glue and preparation method thereof

InactiveCN106634742AGuaranteed adhesion strengthNo bleaching phenomenonABS polymer adhesivesKetoneMaterials science

The invention provides self-prepared glue and a preparation method thereof. The method comprises the following steps of adding a granular injection molding raw material and methyl ethyl ketone into a stirring container according to respective preset mass fractions; stirring methyl ethyl ketone and the granular injection molding raw material by overturning the stirring container, and besides diluting the granular injection molding raw material with the methyl ethyl ketone until the granular injection molding raw material is diluted to be fluid with methyl ethyl ketone. When the self-prepared glue prepared in the invention is used for bonding products, the phenomenon of whitening cannot be generated.

Owner:GOERTEK INC

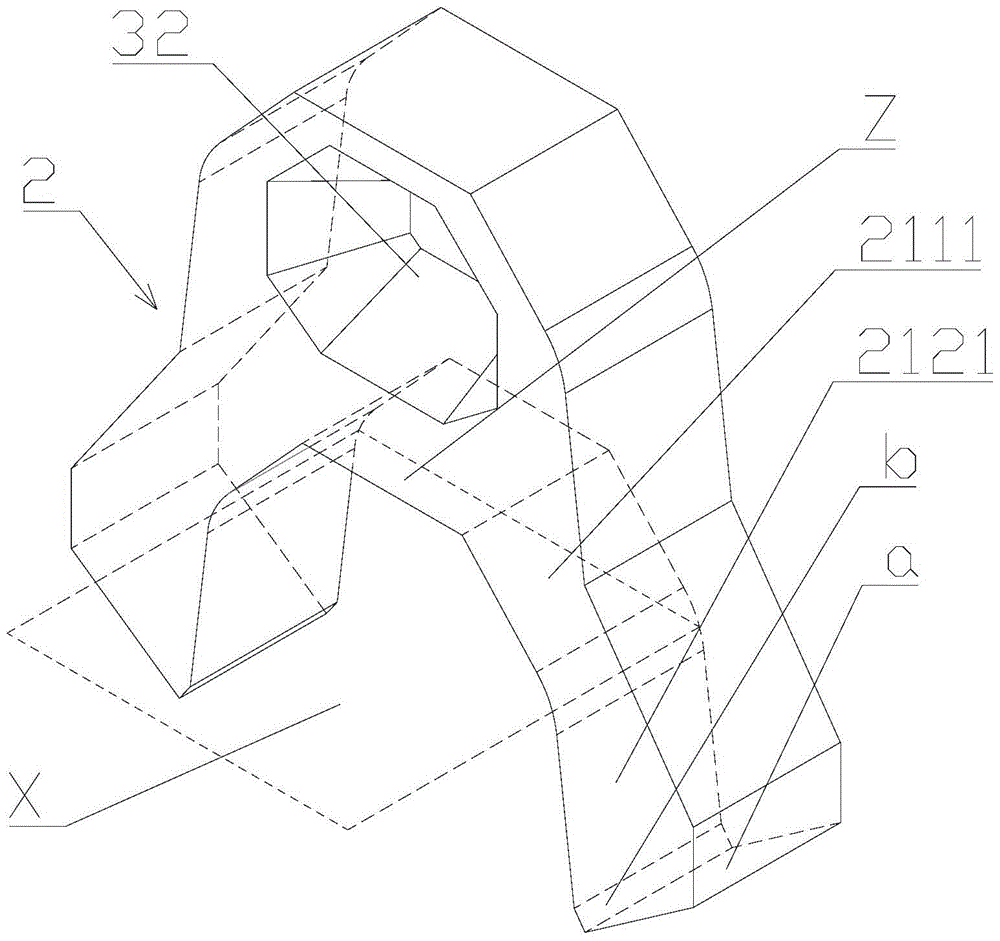

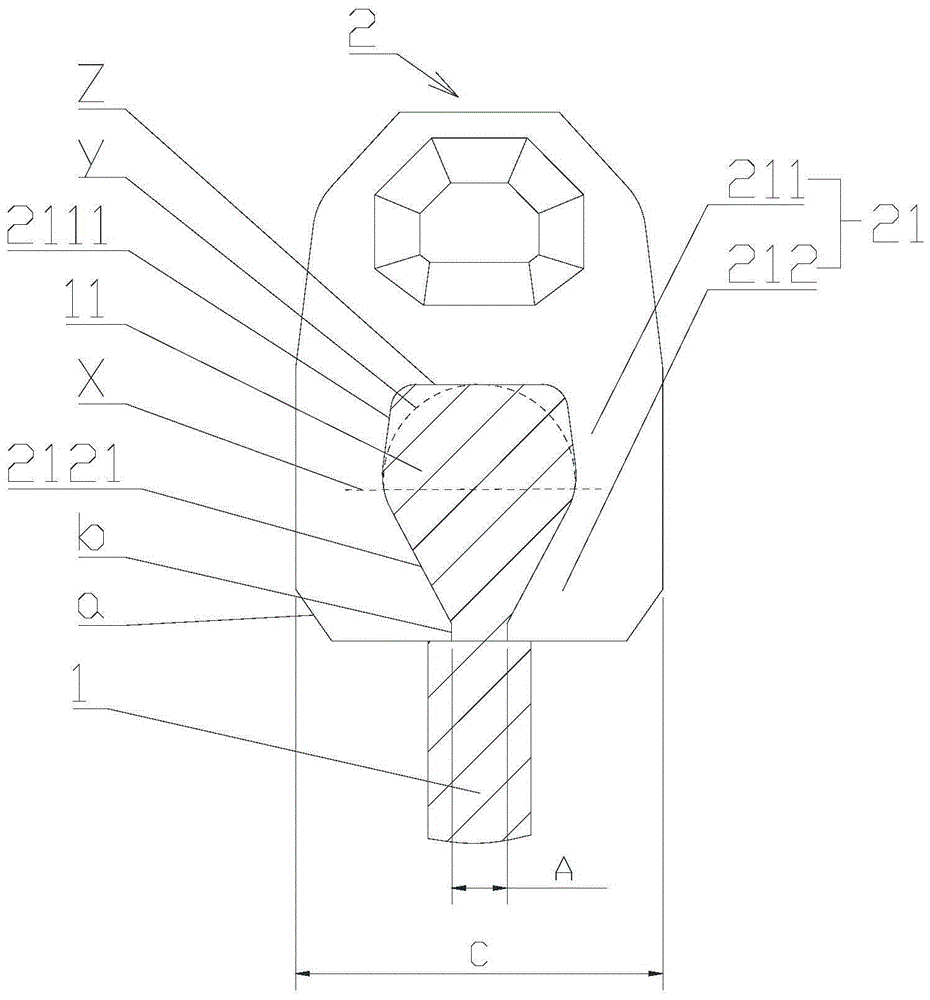

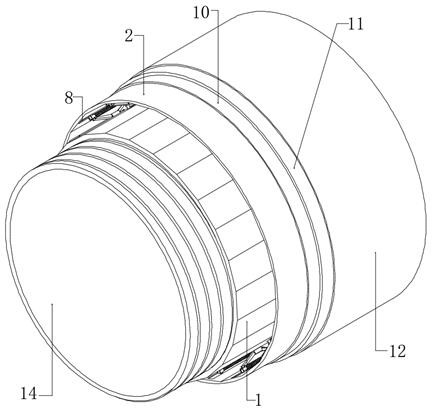

A metal stamping zipper

The invention discloses a metal stamping zipper, which comprises a cloth belt and a chain element. The front side of the cloth tape is provided with a rib, and the rear end of the chain element is provided with a belt for biting the belt rib to fix the chain element on the fabric. The two teeth feet on the belt are arranged symmetrically with respect to the cloth belt, the distance between the rear ends of the two teeth feet is marked as A, the height of the protrusion on the chain teeth is marked as B, and the width of the chain teeth is marked as C, C: A ratio is 2.5-3, B: A ratio is 1.3-1.8. The reasonable setting of the distance between the rear ends of the two teeth feet, the width of the chain element and the height of the protrusion on the chain element makes the metal zipper no matter what size it is processed, even smaller than #2. The strength of the chain teeth is high, the adhesion strength between the chain teeth and the cloth belt, and the fastness of the meshing between the chain teeth are guaranteed at the same time. The chain teeth are not easy to break, and the chain teeth can be firmly attached to the cloth tape and are not easy to fall off.

Owner:KENQING ZHEJIANG ZIPPER

Polymer microsphere with high refractive index and preparation method thereof

The invention relates to the technical field of biological medicines, and discloses a high-refractive-index polymer microsphere, which is prepared from the following raw materials in parts by weight: 100 to 200 parts of aliphatic conjugated diene monomers, 10 to 100 parts of ethylene unsaturated carboxylic acid monomers, 20 to 40 parts of acrylonitrile monomers, 10 to 30 parts of medium-chain fatty glyceride and 5 to 15 parts of aluminum compound aqueous solution. According to the high-refractive-index polymer microsphere and the preparation method thereof, the latex prepared by the method is more stable in structure, lower in production cost, higher in safety and stability in the production process, and capable of effectively inhibiting generation of cracks, various characteristics such as waterproofness, chemical resistance and the like obtained by forming the rubber layer are sufficient, and the high-refractive-index polymer microsphere can be used for preparing the high-refractive-index polymer microsphere. According to the present invention, the prepared latex has the advantages of high tensile strength, sufficient tensile strength of the obtained film molding body such as the dipping molding body, excellent hand feeling and excellent elongation, the controllable production cost can be ensured while the adhesion strength of the latex is ensured, and the product has advantages of high reflectivity and good application effect.

Owner:江苏简芯生物技术有限公司

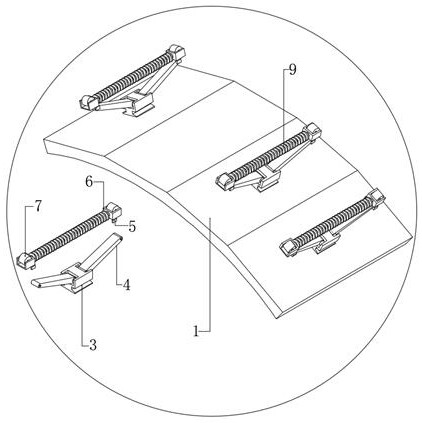

Processing method of breathable counter hot melt adhesive sheet forming die

The invention discloses a processing method of a breathable counter hot melt adhesive sheet forming die. The processing method comprises the following steps that 1, data acquisition, specifically, obtaining that the air direction of a contact surface between a foot and a shoe cavity is upward and air is released to the left and the right during walking; 2, scanning the cross section of an existingcounter hot melt adhesive sheet; 3, modeling, specifically, building a counter hot melt adhesive sheet model with arc-shaped concave strips, arc-shaped convex strips and through holes; and 4, mold processing, specifically, processing a set of concave-convex forming die and micropore punching die according to the breathable counter hot melt adhesive sheet model in the step 3. According to the processing method of the breathable counter hot melt adhesive sheet forming die, a counter hot melt adhesive sheet formed with perspiration channels and exhaust holes can be designed by utilizing a humanbody kinematics theory and a breathable principle, and the function of ensuring the bonding strength of the counter hot melt adhesive sheet to sports shoes can be ensured.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

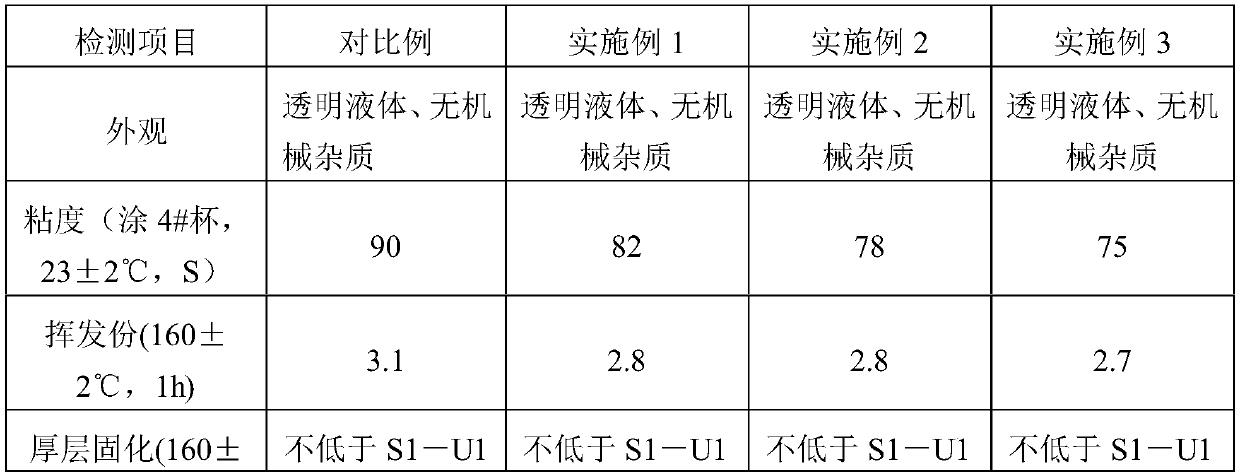

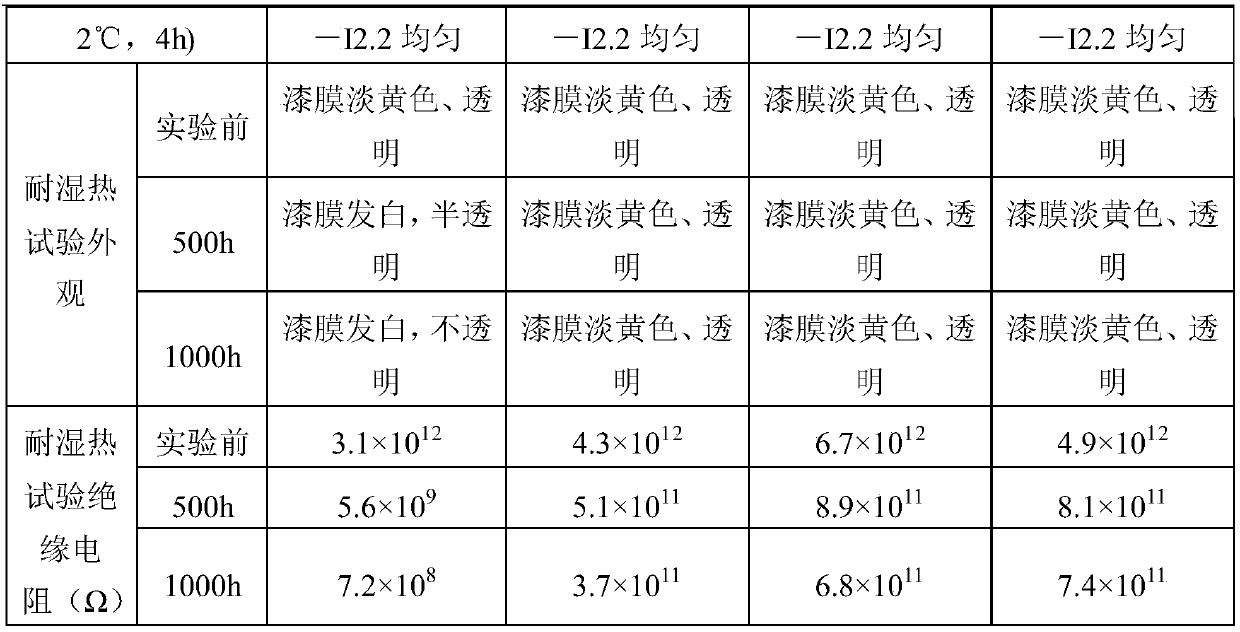

A kind of heat-and-humidity resistant solvent-free dipping varnish and preparation method thereof

ActiveCN106497363BExcellent heat and humidity resistanceEffective protectionFireproof paintsPolyester coatingsSolvent freeSolvent

The invention discloses damp-heat resistant solvent-free impregnating varnish, which is mainly prepared from the following raw materials (by weight): 30-40 parts of polyprotic acid, 5-30 parts of polyol A, 10-40 parts of polyol B, 2-10 parts of a modified imine resin, 25-40 parts of an active diluent, 1-5 parts of auxiliary agents (a stabilizing agent, an initiator and an adhesion auxiliary agent). A preparation method comprises the following steps: adding polyprotic acid, polyol A and polyol B into a reaction vessel and reacting to obtain a prepolymer, adding modified imine resin and reacting, finally adding the stabilizing agent, the mixed diluent, the initiator and the adhesion auxiliary agent and uniformly mixing to obtain the damp-heat resistant solvent-free impregnating varnish. Through polymerization of secondary carbon hydroxymethyl or secondary hydroxyl polyol, tertiary carbon hydroxymethyl polyol and polyacid, alkyl group on the secondary carbon or tertiary carbon can effectively protect ester bond on the secondary carbon or tertiary carbon. Thus, damp-heat resistance of the impregnating varnish is greatly enhanced.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Glass fiber reinforced polyurethane profile coating and coating process

PendingCN114196296AGuaranteed StrengthGuaranteed hardnessFireproof paintsSpecial surfacesEpoxyPolymer science

The invention discloses a glass fiber reinforced polyurethane profile coating and a coating process. The coating comprises a diphenol propane epoxy resin emulsion, a vinyl modified water-soluble emulsion, a polyester resin emulsion, a coalescing agent, a lubricant, a silane coupling agent, aerogel, a PEG softening agent and deionized water. According to the invention, the aerogel is added into the coating and has relatively high compatibility with the profile, so that the surface thickness of the coating can be reduced and the heat resistance and water resistance of the coating can be improved while the strength of the coating of the profile is ensured, and the profile can not generate the conditions of bubbles and skin shedding under the action of high temperature; in the film covering process, an adhesive material with organic materials and high compatibility is adopted to be connected with the outer covering film, and the hardness and the adhesion strength of the coating are guaranteed.

Owner:山东铁斯曼新材料有限公司 +2

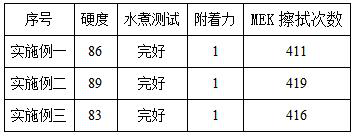

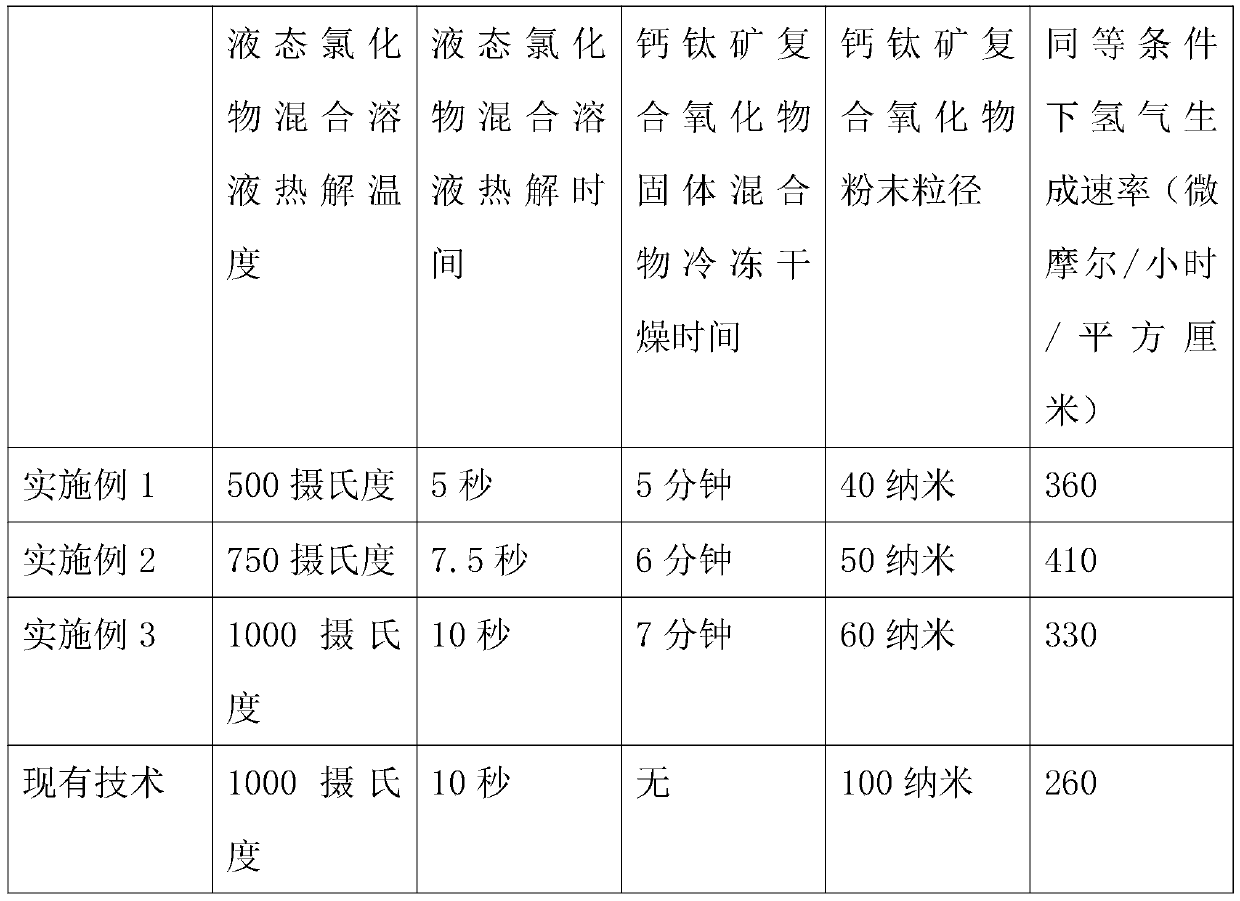

Application method of perovskite complex oxides to hydrogen production by photocatalytic water splitting

InactiveCN109876792AFast manufacturingSimple preparation stepsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic water splittingFreeze-drying

The invention discloses an application method of perovskite complex oxides to hydrogen production by photocatalytic water splitting, and particularly relates to the field of a photocatalysis material.The molecular formula of the perovskite complex oxides is RE1-XBXCO3; x is greater than or equal to 0 but smaller than or equal to 1. The preparation steps of the perovskite complex oxide powder aresimpler; the time required is shorter; the energy required by short-time freeze drying and high-precision grinding is obviously lower than the energy required for long-time roasting; meanwhile, underthe same condition, the hydrogen production speed is obviously higher than that in the prior art; the efficiency of the hydrogen production by photocatalytic water splitting is higher; the method is effectively applicable to the industrialized hydrogen preparation process so as to solve the problem in the prior art.

Owner:LIAOCHENG UNIV

High temperature refractory synthetic crystal insulating tape and its production process

InactiveCN103325505BImprove moisture resistanceGuaranteed uniformityInsulated cablesInsulating bodiesPolyesterEpoxy

Owner:常州欧贝斯绝缘材料有限公司

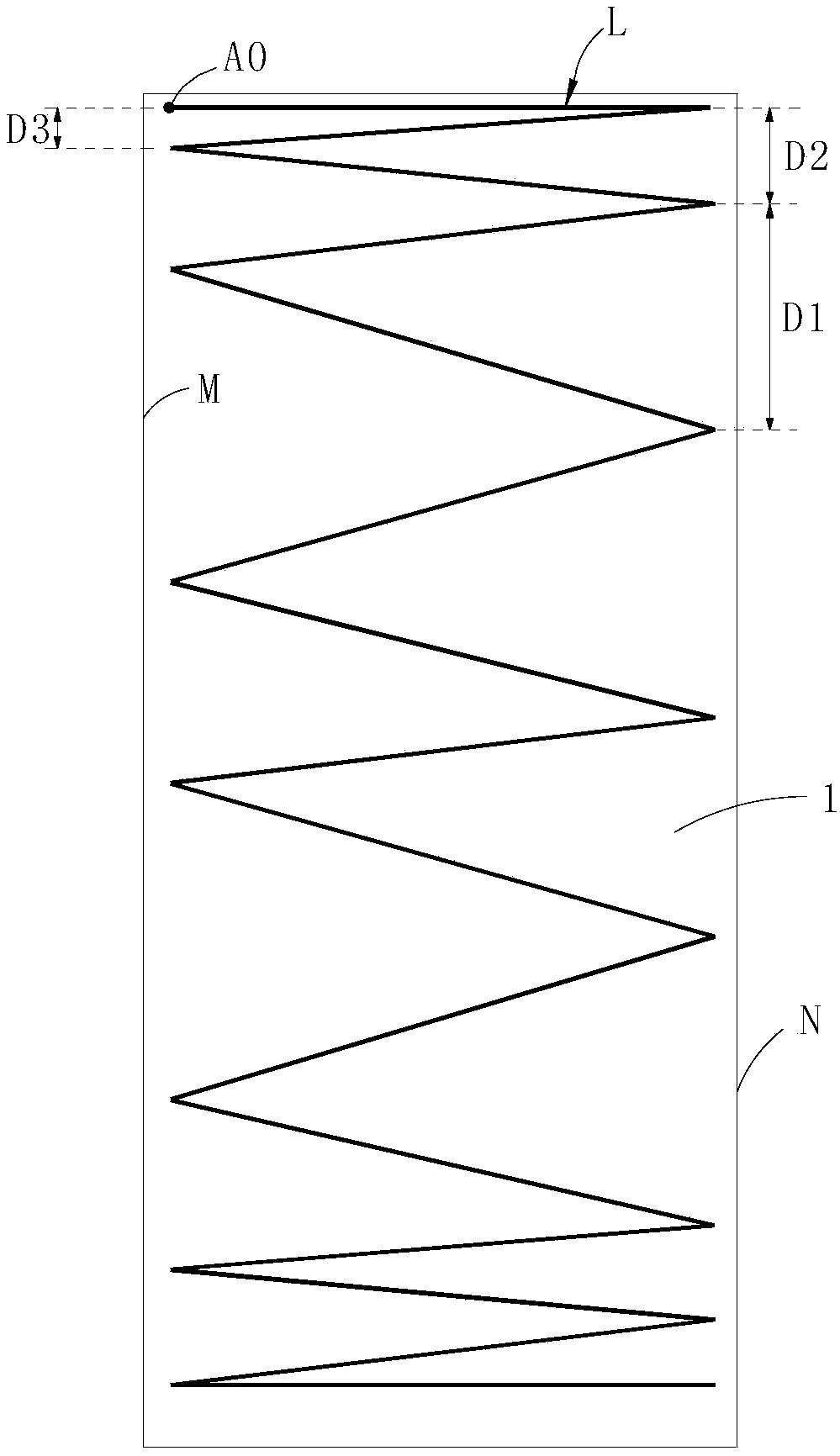

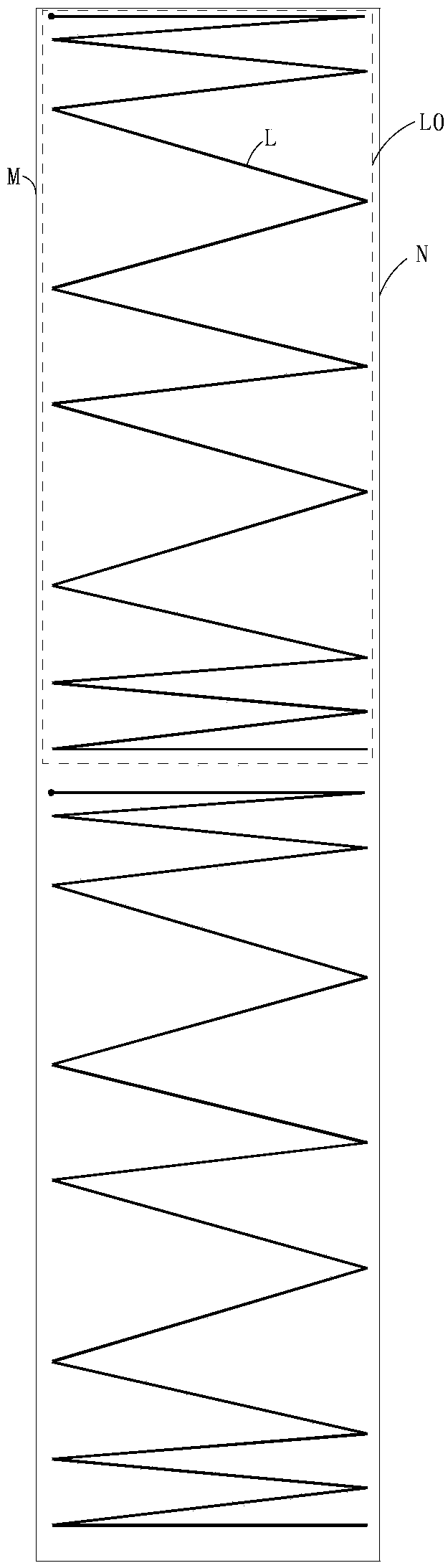

Dispensing method, bonding plate and crystal support for silicon wafer manufacturing

PendingCN111300673AImprove uniformityEasy dischargeWorking accessoriesFine working devicesEdge surfaceEngineering

The invention discloses a dispensing method for manufacturing a silicon wafer. The method comprises the following steps of providing a substrate to be dispensed, wherein the substrate comprises a first side line and a second side line which are oppositely arranged; sequentially coating a plurality of dispensing sections on the substrate to form a dispensing pattern until the starting point and theterminal point of the dispensing pattern are spaced by a preset distance in the length direction of the first side line; in the dispensing pattern, the starting point of each dispensing section is close to the first side line or the second side line, the terminal point of each dispensing section is close to the second side line or the first side line, and the terminal point of the previous dispensing section is the starting point of the next dispensing section. The laminated glue line layer can keep good uniformity, glue overflow can be avoided, air between dispensing sections can be conveniently exhausted, empty glue or glue layer bubbles cannot occur, the defective rate of the edge surface of the silicon wafer caused by uneven stress of a steel wire can be eliminated, and the number ofthe dispensing patterns on the substrate and the glue line spacing of the dispensing patterns can be customized according to the rod length of the silicon rod.

Owner:CHUXIONG LONGI SILICON MATERIALS CO LTD

Mud-resistant cable for oil platform

PendingCN114334244AImproved mud resistanceImprove toughnessInsulated cablesCommunication cablesBuffer (optical fiber)Structural engineering

The invention belongs to the technical field of cables, particularly relates to a mud-resistant cable for an oil platform, and aims to solve the problems that a cable cannot be fixed in mud, solid substances in the mud can be in contact with the outer wall of the cable to collide in the shaking process, and optical fibers in the cable can be repeatedly deformed after frequent collision, so that internal wear is easily caused. Comprising a buffering cavity bottom layer, a buffering cavity top layer is arranged outside the buffering cavity bottom layer, a plurality of pressing seats are arranged on the inner wall of the buffering cavity bottom layer, the pressing seats are distributed at equal intervals in the circumferential direction, and symmetrical rectangular grooves are formed in the pressing seats. The buffer cavity is additionally arranged in the designed cable, the cable is suitable for being used in the slurry environment in the oil exploitation process, pressure applied to the outside of the cable can be buffered and offset through the overturning plate and the reset spring distributed in the buffer cavity, and the situation that the pressure is transmitted to optical fibers in the cable, and the optical fibers are damaged under continuous impact is avoided; and the slurry resistance of the cable is improved.

Owner:ANHUI CABLE

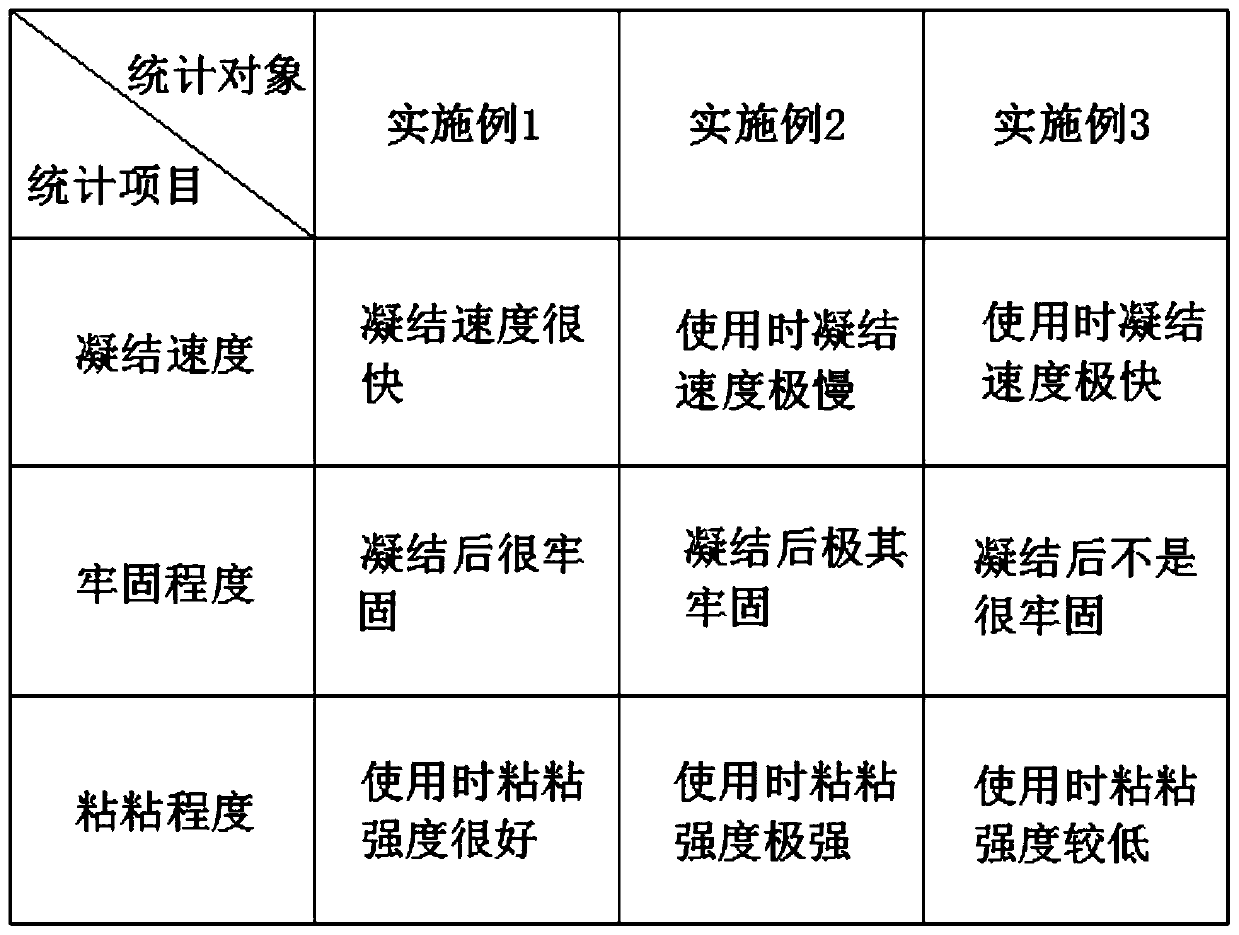

Transparent polyurethane paint for dyed veneer and preparation method of transparent polyurethane paint

InactiveCN110591530AFast condensationHigh strengthPolyurea/polyurethane coatingsCyclohexanoneWhitening Agents

The invention discloses transparent polyurethane paint for dyed veneer and a preparation method of the transparent polyurethane paint. The raw materials of the transparent polyurethane paint include,in parts by weight, 30-45 parts of polyurethane resin, 10-20 parts of xylene, 10-20 parts of butyl acetate, 4-6 parts of cyclohexanone, 4-8 parts of a cyanoacetoxy compound, 4-6 parts of a polyvinyl acetate emulsion, 10-15 parts of 107 glue, 4-5 parts of a whitening agent, 2-6 parts of a flocculant and 6-10 parts of clear water. The invention relates to the technical field of polyurethane paint. According to the transparent polyurethane paint for dyed veneer and the preparation method of the transparent polyurethane paint, the produced transparent polyurethane paint has three characteristics,a high condensation speed, more convenient use and a wider application range, use of the transparent polyurethane paint is not restricted, application is facilitated, and the problems are solved thatadhesion viscosity, adhesion strength and drying speed of existing transparent polyurethane paint cannot be ensured at the same time due to limitation of materials, and it is ensured that only one ofthe three indexes can be met.

Owner:君子兰涂料(天津)有限公司

Preparation method of injector-shaped ZnO nanostructural array for field emission

InactiveCN102061498BGuaranteed adhesion strengthFor controlled growthPolycrystalline material growthLiquid-phase epitaxial-layer growthSynthesis methodsTwo step

The invention relates to a preparation method of an injector-shaped ZnO nano-structural array for field emission, which is a two-step synthesis method based on an aqueous solution system. The method comprises the following steps: firstly, adopting a electrochemical deposition method to directly grow a ZnO nano-column array on a conductive glass substrate; and secondly, adopting the aqueous solution chemical growing method to perform epitaxial growth of nano-needles on the original end surfaces of the ZnO nano-columns. The injector-shaped ZnO nano-structural array is prepared by the two-step synthesis method, thus the adhesive strength of the ZnO nano-structural array on the conductive substrate can be ensured, the electrical conductivity can be increased, the controllable growth of the pointed nanostructure, which is beneficial for electron emission can be realized and the field emission performance of the array structure can be improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com