Glass fiber reinforced polyurethane profile coating and coating process

A technology for polyurethane profiles and coatings, applied in polyester coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve the problems of poor thermal insulation performance and hardness test, easy peeling of skin, etc., to increase heat resistance and water resistance. performance, reduced surface thickness, guaranteed hardness and effect of adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

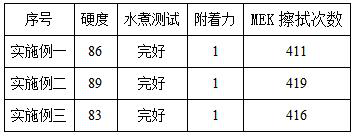

Examples

Embodiment 1

[0027] The coating process of glass fiber reinforced polyurethane profile coating comprises the following steps:

[0028] Diphenol-based propane type epoxy resin emulsion 2kg, vinyl modified water-soluble emulsion 0.5kg, polyester resin emulsion 5kg, propylene glycol butyl ether 6kg, lubricant 0.5kg, γ-methacryloxypropyl trimethoxy Add 6kg of silane, 1kg of cationic benzylaminosilane, 10kg of airgel, 0.2kg of polyethylene glycol and 42kg of deionized water into a stirring tank, mix and heat, then dehydrate and cool to room temperature to obtain a coating;

[0029] Surface-treat the impregnated glass fiber and polyurethane profile base material to remove impurities such as oxides; use a coating machine to quickly cover the surface of the base material; spray a layer of functional coating or coating on the outer surface of the coating material as required Premade patterns.

Embodiment 2

[0031] The coating process of glass fiber reinforced polyurethane profile coating comprises the following steps:

[0032] Diphenol-based propane type epoxy resin emulsion 3kg, vinyl modified water-soluble emulsion 0.7kg, polyester resin emulsion 7kg, propylene glycol butyl ether 12kg, lubricant 3kg, γ-methacryloxypropyl trimethoxysilane 4kg, 0.6kg of cationic benzylaminosilane, 13kg of airgel, 1kg of polyethylene glycol and 55kg of deionized water were added to a stirring tank, mixed and heated, then dehydrated and cooled to room temperature to obtain a coating;

[0033] Surface-treat the impregnated glass fiber and polyurethane profile base material to remove impurities such as oxides; use a coating machine to quickly cover the surface of the base material; spray a layer of functional coating or coating on the outer surface of the coating material as required Premade patterns.

Embodiment 3

[0035] The coating process of glass fiber reinforced polyurethane profile coating comprises the following steps:

[0036] Diphenol-based propane type epoxy resin emulsion 5kg, vinyl modified water-soluble emulsion 1kg, polyester resin emulsion 8kg, propylene glycol butyl ether 18kg, lubricant 5kg, γ-methacryloxypropyl trimethoxysilane 3kg , 0.5 kg of cationic benzylaminosilane, 16 kg of airgel, 1.5 kg of polyethylene glycol and 40 kg of deionized water were added to a stirring tank, mixed and heated, then dehydrated and cooled to normal temperature to obtain a coating;

[0037] Surface-treat the impregnated glass fiber and polyurethane profile base material to remove impurities such as oxides; use a coating machine to quickly cover the surface of the base material; spray a layer of functional coating or coating on the outer surface of the coating material as required Premade patterns.

[0038] The amount of glue applied to the paint is 12g / m2, and the substrate is dried at 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com