A kind of heat-and-humidity resistant solvent-free dipping varnish and preparation method thereof

A solvent-free impregnating paint, heat-and-moisture-resistant technology, applied in coatings, polyester coatings, fire-retardant coatings, etc., can solve the problems of poor heat-and-moisture resistance and limited breadth, achieve excellent heat-and-moisture resistance, ensure heat-and-moisture resistance, and improve paint The effect of film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

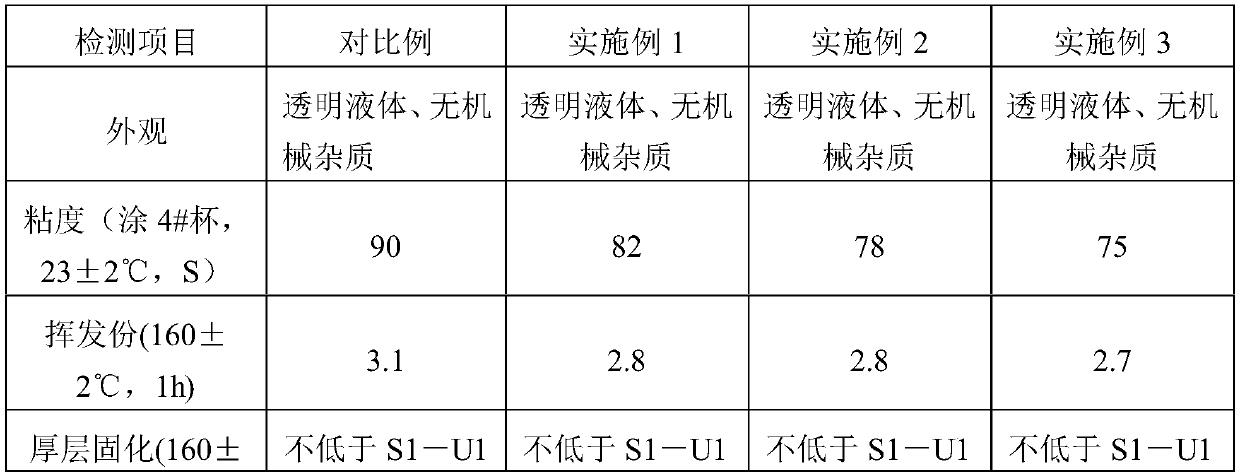

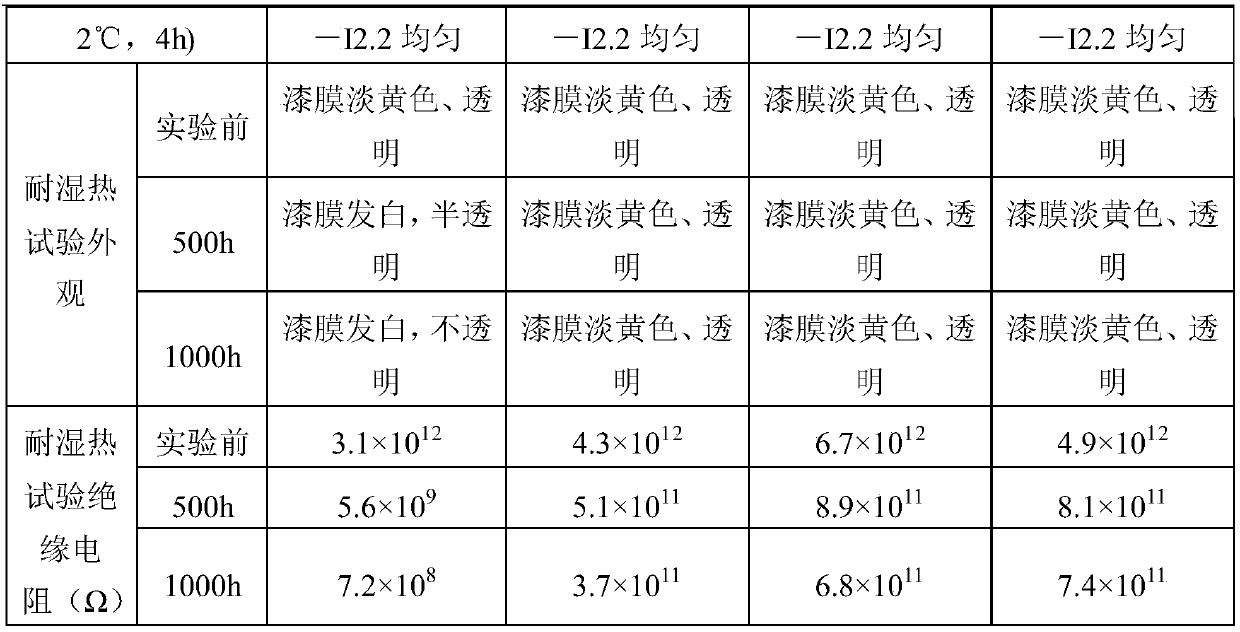

Examples

Embodiment 1

[0033] A heat-and-humidity resistant solvent-free impregnating varnish of the present invention is prepared from the following raw materials in parts by weight:

[0034] 32kg polybasic acid (8kg isophthalic acid, 6kg succinic acid, 18kg maleic anhydride),

[0035] 28kg polyol A (3kg Saike, 15kg neopentyl glycol, 10kg dipropylene glycol),

[0036] 12kg polyol B (2-butyl-2-ethyl 1,3-propanediol),

[0037] 3kg modified imine resin (tetrahydrophthalic anhydride imine ethyl alcohol),

[0038] 28kg reactive diluent (vinyltoluene),

[0039] 0.1kg stabilizer (hydroquinone),

[0040] 1.2kg initiator (cumene peroxide),

[0041] 0.8 kg of adhesion promoter (vinyl tri-tert-butyl silicon peroxide).

[0042] The preparation method of the heat-and-humidity resistant solvent-free dipping varnish of the present embodiment, comprises the following steps:

[0043] (1) Add 12kg of 2-butyl-2-ethyl 1,3-propanediol, 8kg of isophthalic acid, 3kg of Saike, and 6kg of neopentyl glycol into the re...

Embodiment 2

[0046] A heat-and-humidity resistant solvent-free dipping varnish of the present invention is mainly prepared from the following raw materials in parts by weight:

[0047] 39kg polybasic acid (6kg trimellitic anhydride, 4kg adipic acid, 21kg maleic acid, 8kg dimer fatty acid),

[0048] 13kg Polyol A (6kg Neopentyl Glycol, 7kg Hexylene Glycol),

[0049] 24kg polyol B (16kg2,2,4-trimethyl-1,3-pentanediol, 8kg1,4-cyclohexanedimethanol),

[0050] 6kg modified imine resin (methyltetrahydrophthalic anhydride imine ethyl alcohol),

[0051] 38kg reactive diluent (diallyl phthalate),

[0052] 0.06kg2-tert-butylhydroquinone,

[0053] 0.01kg methyl hydroquinone,

[0054] 1kg tert-butyl perbenzoate,

[0055] 0.2 kg of vinylmethyldi-tert-butylperoxysilane.

[0056] The preparation method of the heat-and-humidity resistant solvent-free dipping varnish of the present embodiment, comprises the following steps:

[0057] (1) Add 16kg of 2,2,4-trimethyl-1,3-pentanediol, 8kg of 1,4-cyclohe...

Embodiment 3

[0060] A heat-and-humidity resistant solvent-free dipping varnish of the present invention is mainly prepared from the following raw materials in parts by weight:

[0061] 33kg polybasic acid (6kg phthalic anhydride, 9kg sebacic acid, 18kg maleic anhydride),

[0062] 8kg polyol A (neopentyl glycol),

[0063] 39kg polyol B (19kg 2-butyl-2-ethyl 1,3-propanediol, 20kg hydrogenated bisphenol A),

[0064] 8kg imine resin (methyltetrahydrophthalic anhydride imide ethyl alcohol),

[0065] 26kg reactive diluent (styrene),

[0066] 0.1kg 2,5-di-tert-butylhydroquinone,

[0067] 1kg ethyl-3,3-bis(tert-butylperoxy)butyrate,

[0068] 3.2kg 1,1-tert-butyl-diperoxy-4-hydroxycyclohexyltrimethoxysilane.

[0069] The preparation method of the heat-and-humidity resistant solvent-free dipping varnish of the present embodiment:

[0070] (1) Add 19kg of 2-butyl-2-ethyl 1,3-propanediol, 20kg of hydrogenated bisphenol A and 6kg of phthalic anhydride into the reaction kettle, and after mixing ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com