Rubber double-sealing structure for underwater motor cable

An underwater motor, double-sealed technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of inability to adapt to the installation environment of the rim propulsion motor cable, the size of the connector or sleeve, and the vibration reduction of the rim motor. Noise adverse effects and other problems, to achieve the effect of improving watertight performance, increasing adhesion strength, and ensuring overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

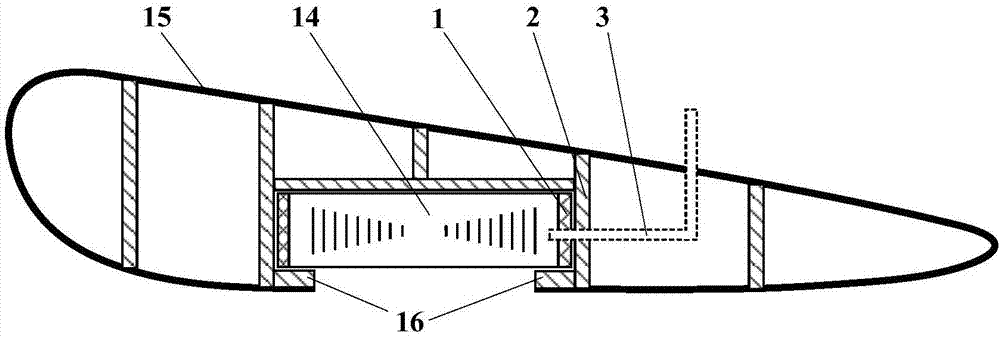

[0022] figure 1 Shows the axial outlet solution of the power cable of the rim motor. The stator of the rim motor is installed on the base 16 of the duct 15 in an embedded manner. The cable 3 is axially exited from the end of the motor through the motor end plate 1 and then through the duct wall 2 through the watertight device. 3 Sealing with the motor end plate 1 and the duct wall plate 2.

[0023] Since the stator of the motor is installed in the duct in an embedded manner, there is a gap between the mating surfaces of the motor end plate 1 and the duct wall plate 2. When the rim motor is in a deep water environment, sea water is very likely to pass through the cooling channel of the motor Into this gap, the cable 3 needs to be water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com