Application method of perovskite complex oxides to hydrogen production by photocatalytic water splitting

A technology of composite oxides and application methods, which is applied in the field of photocatalytic hydrogen production from perovskite composite oxides, can solve the problems of ineffective application of industrialized water to hydrogen production, long preparation time, and high energy consumption for preparation. The required time is short, the preparation steps are simple, and the effect of ensuring solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

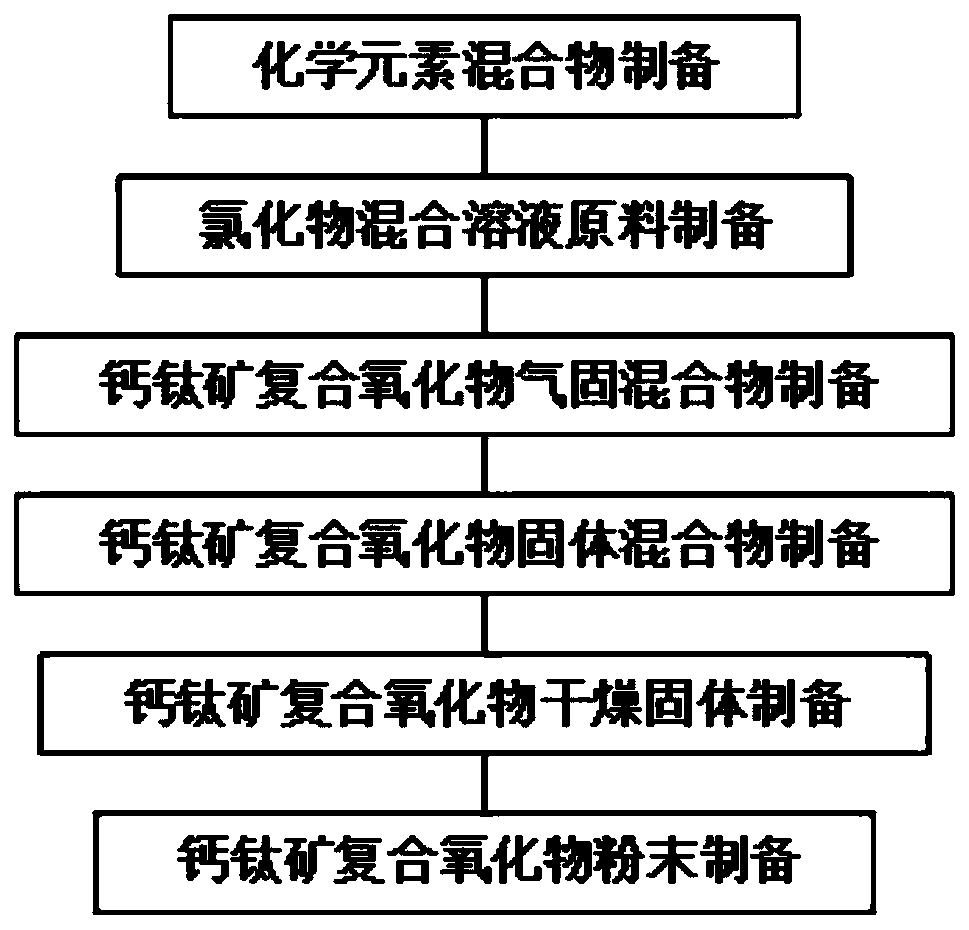

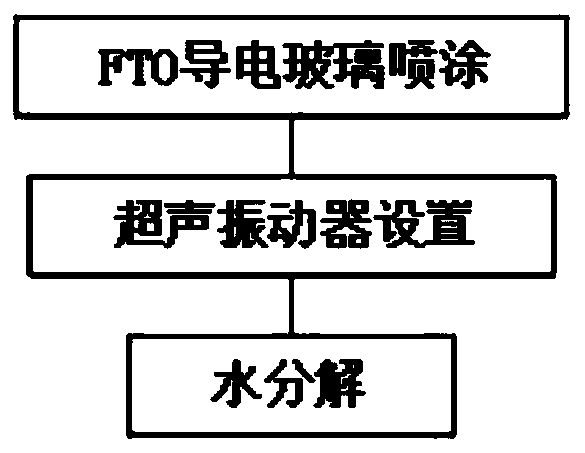

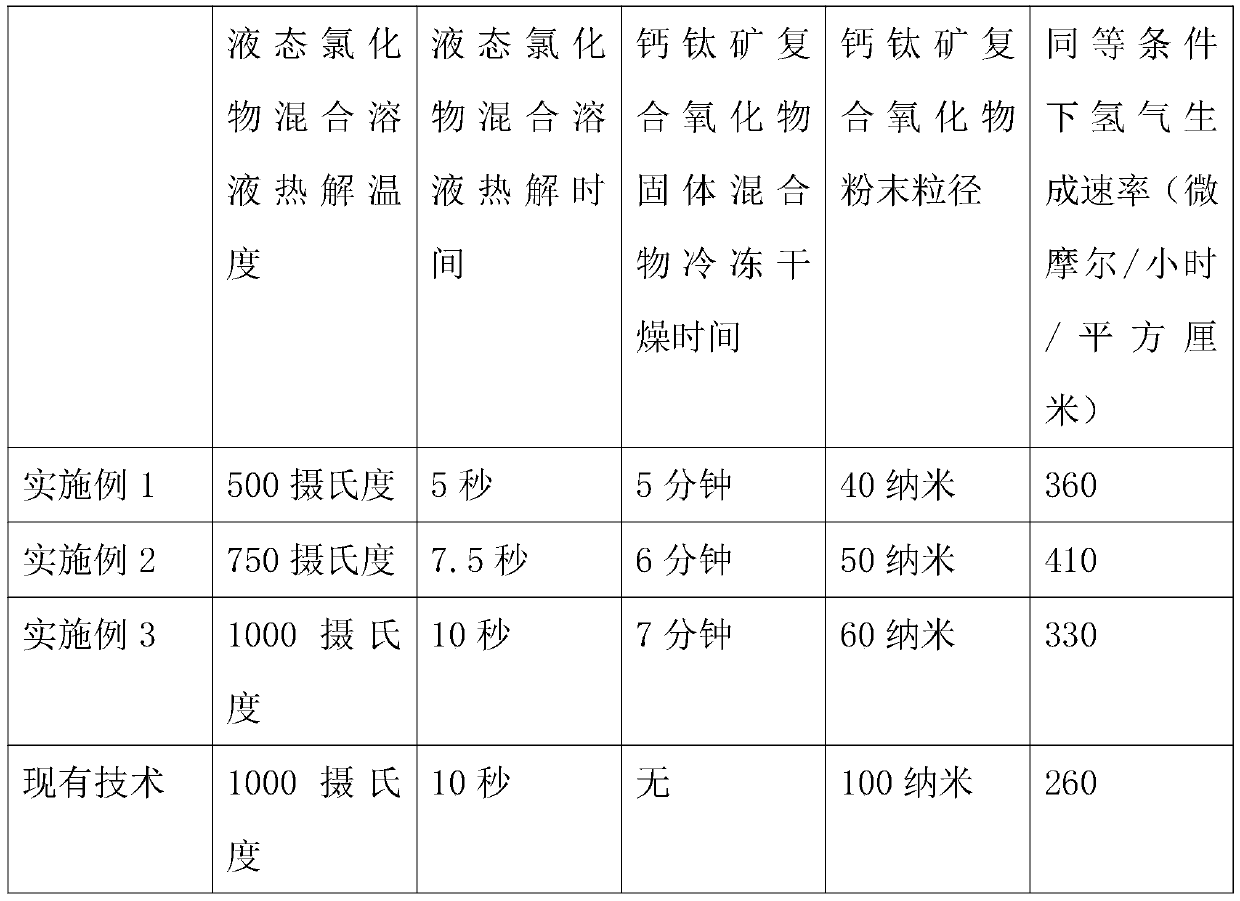

[0032] The present invention provides such as Figure 1-2 The application method of a kind of perovskite composite oxide shown in photocatalytic water splitting hydrogen production, described perovskite composite oxide molecular formula is RE 1-X B X CO 3 , 0≤x≤1, the perovskite composite oxide has a porous microscopic appearance, RE is set to La, Ce, Pr, Nd, Sm or Eu, B and C are different or the same transition metal, alkali metal or alkaline earth metals;

[0033] Concrete preparation method comprises the following steps:

[0034] S1. Preparation of chemical element mixture: select the set chemical elements according to the actual situation, and then mix the selected chemical elements according to the stoichiometric molar ratio according to the chemical composition of the perovskite composite oxide molecular formula to prepare the chemical element mixture;

[0035] S2. Preparation of the raw material of the chloride mixed solution: dissolving the chemical element mixtur...

Embodiment 2

[0046] The present invention provides such Figure 1-2 The application method of a kind of perovskite composite oxide shown in photocatalytic water splitting hydrogen production, described perovskite composite oxide molecular formula is RE 1-X B X CO 3 , 0≤x≤1, the perovskite composite oxide has a porous microscopic appearance, RE is set to La, Ce, Pr, Nd, Sm or Eu, B and C are different or the same transition metal, alkali metal or alkaline earth metals;

[0047] Concrete preparation method comprises the following steps:

[0048] S1. Preparation of chemical element mixture: select the set chemical elements according to the actual situation, and then mix the selected chemical elements according to the stoichiometric molar ratio according to the chemical composition of the perovskite composite oxide molecular formula to prepare the chemical element mixture;

[0049] S2. Preparation of the raw material of the chloride mixed solution: dissolving the chemical element mixture i...

Embodiment 3

[0060] The present invention provides such Figure 1-2 The application method of a kind of perovskite composite oxide shown in photocatalytic water splitting hydrogen production, described perovskite composite oxide molecular formula is RE 1-X B X CO 3 , 0≤x≤1, the perovskite composite oxide has a porous microscopic appearance, RE is set to La, Ce, Pr, Nd, Sm or Eu, B and C are different or the same transition metal, alkali metal or alkaline earth metals;

[0061] Concrete preparation method comprises the following steps:

[0062] S1. Preparation of chemical element mixture: select the set chemical elements according to the actual situation, and then mix the selected chemical elements according to the stoichiometric molar ratio according to the chemical composition of the perovskite composite oxide molecular formula to prepare the chemical element mixture;

[0063] S2. Preparation of the raw material of the chloride mixed solution: dissolving the chemical element mixture i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com