Adhesive tape and display device using same

A tape and display panel technology, applied in the direction of adhesive, film/sheet adhesive, optics, etc., can solve the problems of scrapping the display, returning the display device to the factory for heavy work, increasing the cost of the defective liquid crystal display device, etc., to ensure the adhesion strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

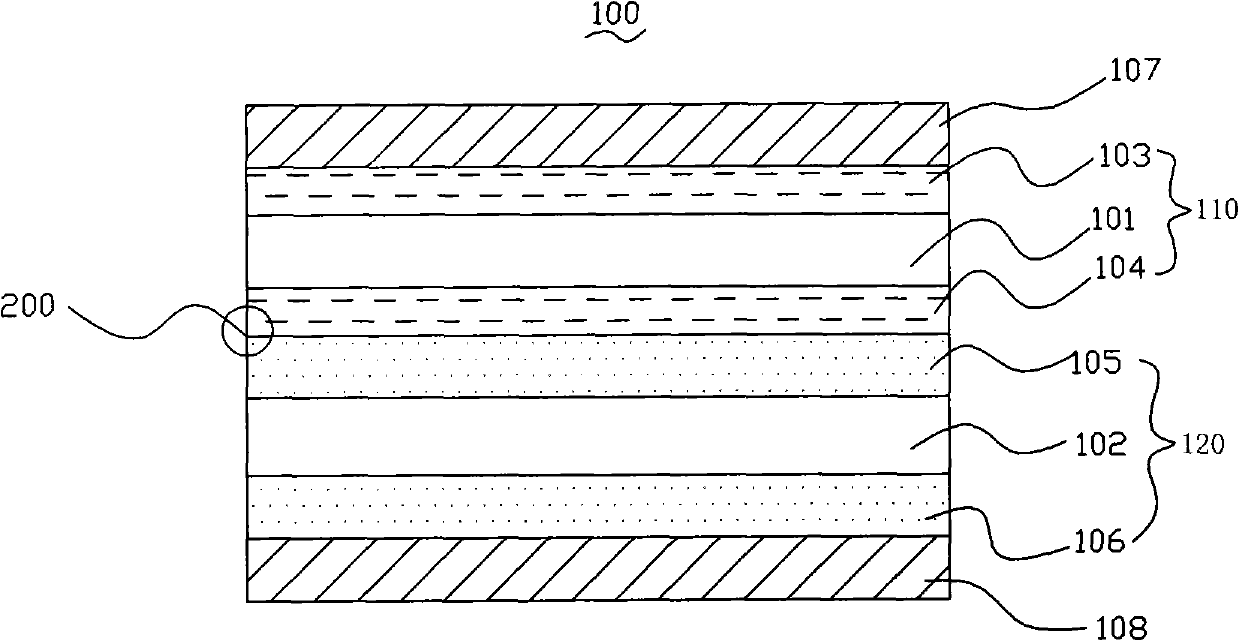

[0021] See figure 2 , figure 2 Shown is a structural diagram of the adhesive tape of the present invention. As shown in the figure, the adhesive tape 100 is composed of two layers of sub-adhesive tapes, wherein the first sub-adhesive tape 110 has a first adhesive layer 103, a second adhesive layer 104 and a first substrate layer 101, the first adhesive layer 103 and The second adhesive layer 104 is respectively arranged on both sides of the first base material layer 101; The fourth adhesive layer 106 is respectively disposed on two sides of the second substrate layer 102 , wherein the third adhesive layer 105 is connected to the second adhesive layer 104 . On the outside of the first adhesive layer 103 and the fourth adhesive layer 106 are respectively provided with a first release layer 107 and a second release layer 108, the first release layer 107 and the second release layer 108 can be The adhesive tape 100 is peeled off before use.

[0022] Between the first sub-adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com