A metal stamping zipper

A zipper and metal technology, which is applied in the field of metal stamping zippers, can solve the problems of chain teeth falling off, poor strength of chain teeth, and easy breakage of tooth feet, and achieve the effect of not easy to break, not easy to fall off, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

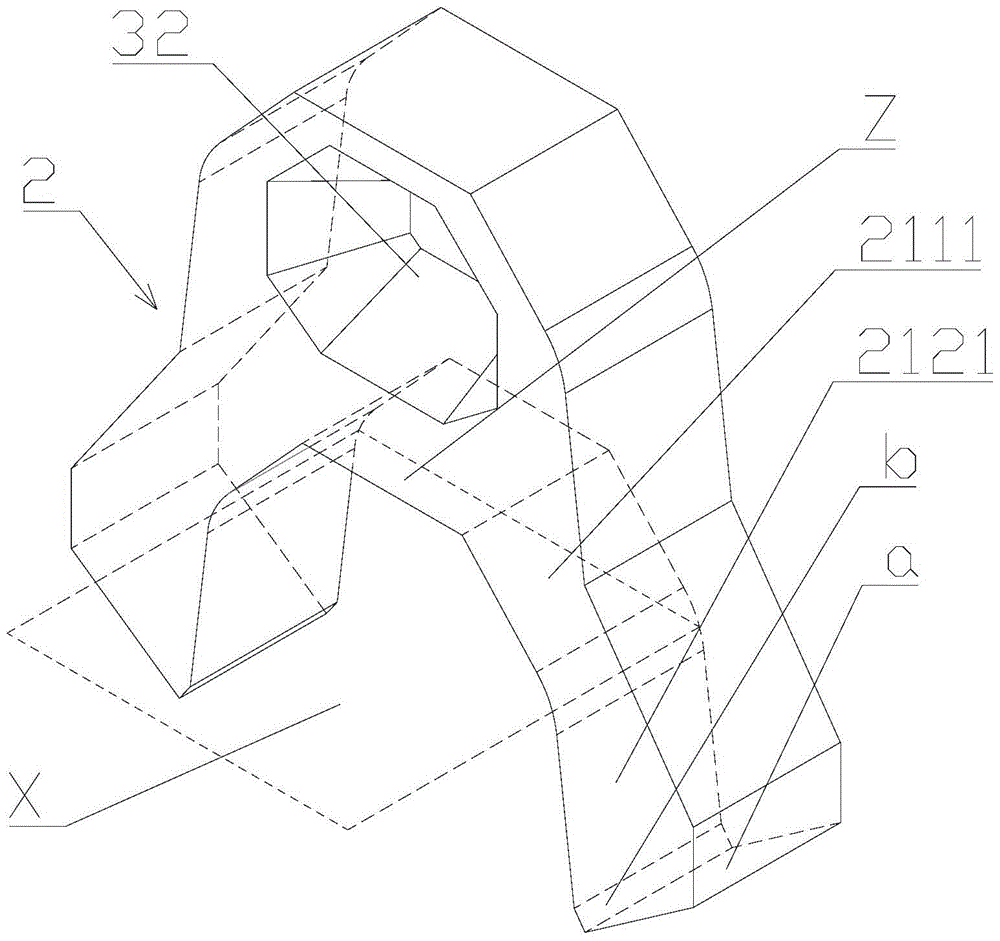

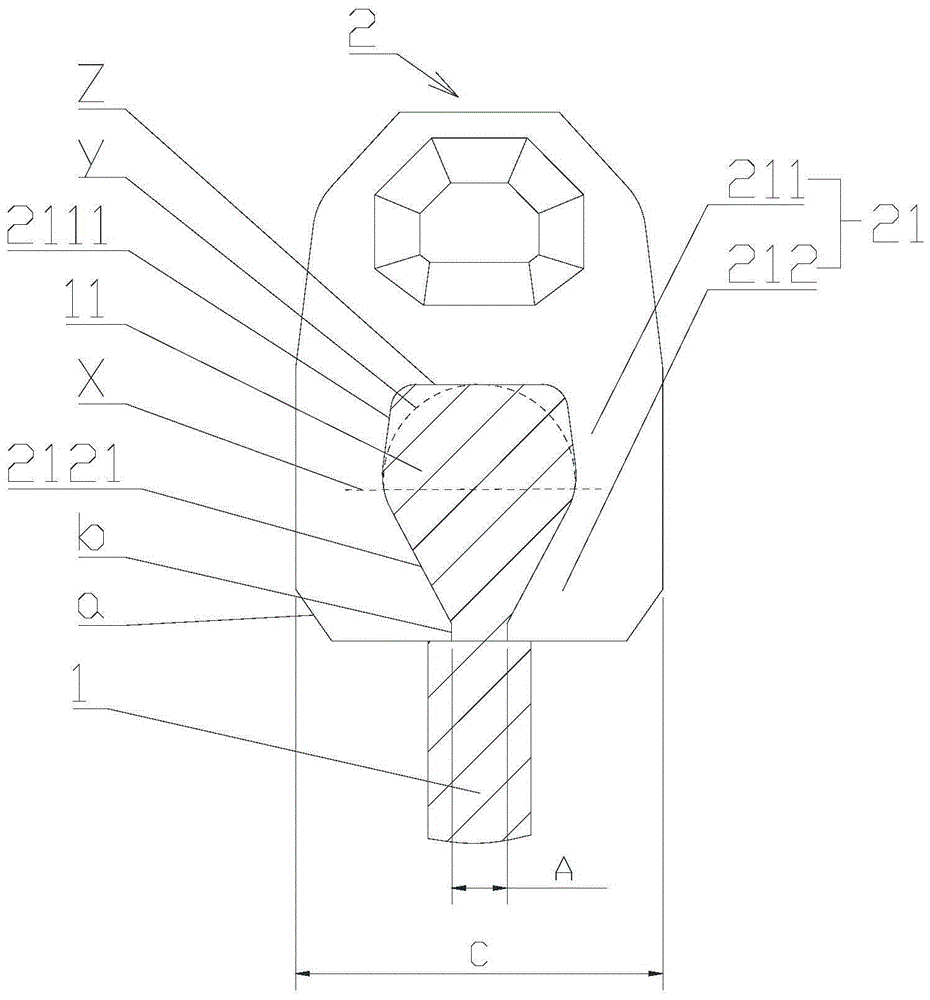

[0027] Such as Figure 1 to Figure 5As shown, a metal stamping zipper includes a cloth tape 1 and a chain element 2. The front side of the cloth tape is provided with a rib 11, and the rear end of the chain element is provided with a rib for biting the chain element to fix the chain element. The two tooth feet 21 on the cloth tape, when the cloth tape is flattened, the two tooth feet are symmetrically arranged with respect to the cloth tape, the rear end surface of the tooth foot is perpendicular to the cloth tape, and the outer surface of the tooth foot is perpendicular to the tooth foot. The rear end surface is set, and the outer surface of the tooth foot and the rear end surface of the tooth foot are transitioned through a slope a, and the tooth foot includes a root portion 211 and an occlusal portion 212 extending backward from the root portion to bite the rib. The inner surface 2111 of the root is a plane, the inner surface 2121 of the occlusal part is a plane, the inner ...

Embodiment 2

[0032] Such as Figure 6 As shown, this embodiment is similar to the first embodiment, the difference is that the inner surface of the above-mentioned root of the fastener element 2 is set as an elliptical arc surface.

Embodiment 3

[0034] This embodiment is similar to the first embodiment, except that A is 0.49 mm, B is 0.74 mm, C is 1.35 mm, C: A is 2.76, and B: A is 1.51.

[0035] The metal punching zipper of the present invention can be processed into a zipper of extremely small size, and will not be broken or teeth will fall off during use, and has substantial use value and practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com