High temperature fire-proof synthetic crystal insulating tape and production process thereof

A high-temperature refractory and production technology technology, applied in the direction of insulators, insulators, insulated cables, etc., can solve the problems of high-temperature-resistant cables being pushed back, not having moisture-proof function, and cable damage, and achieve the effect of improving flame-retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

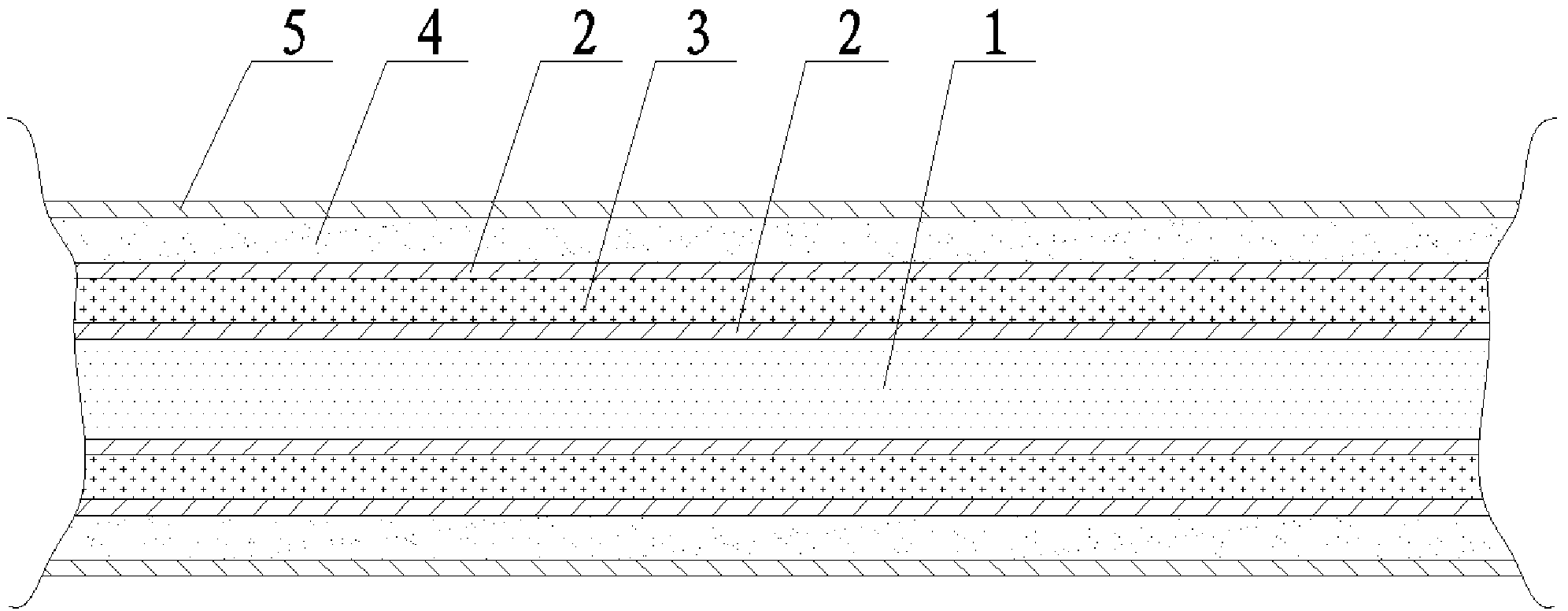

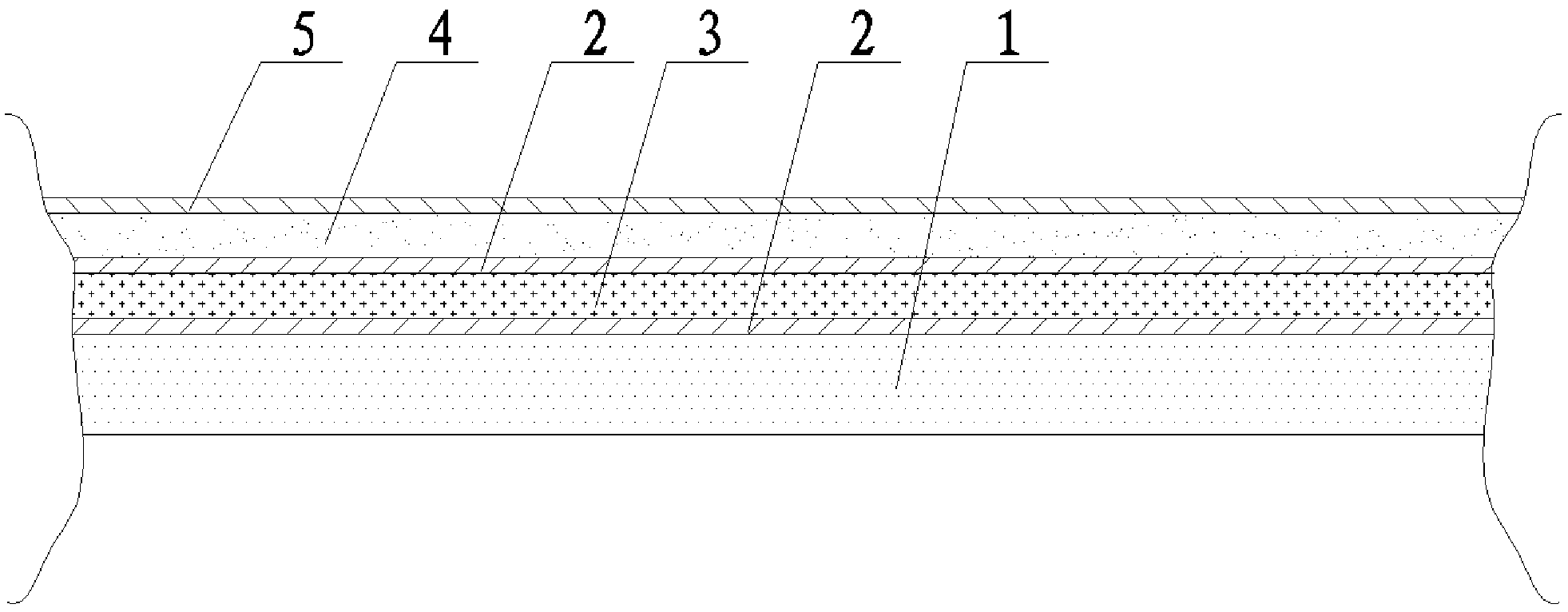

[0032] Such as figure 1 with figure 2 As shown, it shows a specific embodiment of the high temperature refractory synthetic crystal insulating tape of the present invention, figure 2 shows a single-sided synthetic mica tape comprising a six-layer structure, figure 1 A double-sided synthetic mica tape comprising an eleven-layer structure is shown;

[0033] The above six layers of single-sided synthetic mica tape are as follows from top to bottom: flame retardant layer 5, polyester film 4, adhesive layer 2, alkali-free glass cloth 3, adhesive layer 2, synthetic mica paper 1;

[0034] The above eleven layers of double-sided synthetic mica tapes are as follows from top to bottom: flame retardant layer 5, polyester film 4, adhesive layer 2, alkali-free glass cloth 3, adhesive layer 2, synthetic mica paper 1, adhesive Layer 2, alkali-free glass cloth 3, adhesive layer 2, polyester film 4, flame retardant layer 5;

[0035] The adhesive layer adopts organic silicon resin or epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com