One-large two-small umbrella-shaped DC composite post insulator used for high altitude area

A post insulator and high-altitude technology, applied in the field of DC composite post insulators and their shed structures, can solve the problems of increasing creepage distance insulators, and the research is still blank, so as to improve the pollution flashover voltage, optimize the shed structure, enhance Effect of External Insulation Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the implementation and protection of the present invention are not limited thereto. If there are no specific details below, those skilled in the art can refer to the prior art.

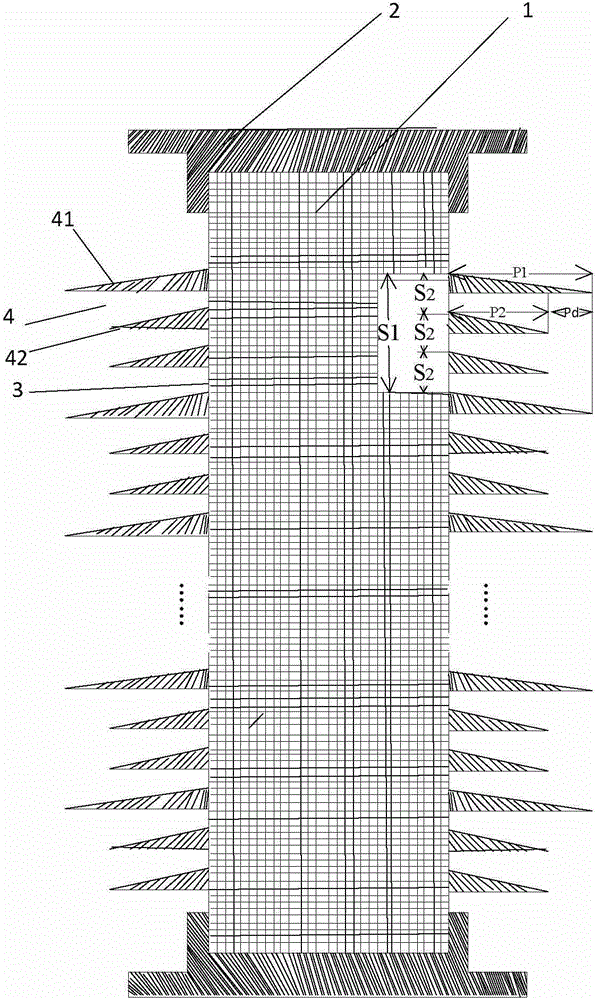

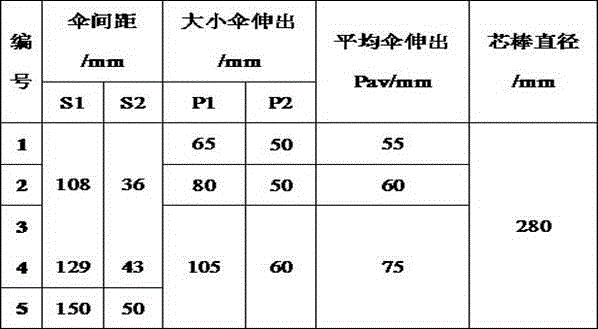

[0021] figure 1 The shown DC composite post insulator adopts the shed structure optimized by the present invention, figure 1 Medium, P 1 Stretch out for the big shed umbrella, P 2 Stretch out for the small umbrella skirt umbrella, S 1 is the spacing between the large sheds and sheds, S 2 is the spacing between adjacent sheds, P 1 and P 2 mean value of P AV =(P 1 +2P 2 ) / 3 is the average umbrella extension.

[0022] It is mainly composed of three parts: glass core rod 1, outer shed (silicone rubber sheath 3, silicone rubber shed 4), metal flange 2, and the silicone rubber shed 4 consists of sheds from top to bottom. One shed unit is composed of a large shed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com