Self-prepared glue and preparation method thereof

A technology of glue and mass fraction, applied in the direction of adhesives, adhesive types, acrylonitrile butadiene styrene polymer adhesives, etc., can solve the problems of glue whitening, etc., and achieve the effect of ensuring the adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

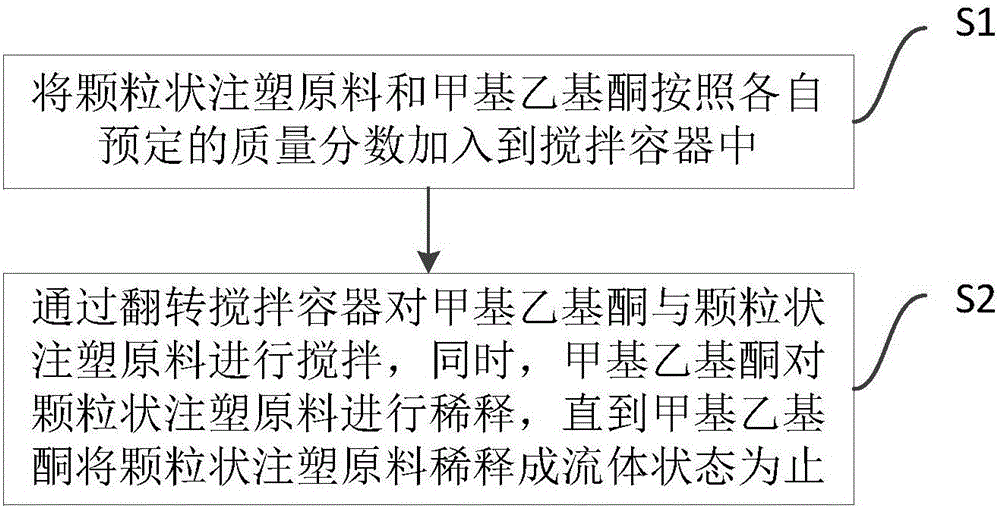

Method used

Image

Examples

Embodiment 1

[0018] The self-made glue provided in this embodiment 1 is composed of granular injection molding raw materials and methyl ethyl ketone, wherein the mass fraction of granular injection molding raw materials is 10%, the mass fraction of methyl ethyl ketone is 90%, and the granular Granular injection molding raw materials and methyl ethyl ketone are mixed according to their respective mass fractions, and the final mixture of granular injection molding raw materials and methyl ethyl ketone is in a fluid state.

[0019] The granular injection molding raw material in Embodiment 1 includes any one of acrylonitrile-butadiene-styrene copolymer, polycarbonate, polypropylene and polyvinyl chloride, that is, the composition of granular injection molding is single, and it cannot be the above-mentioned several a mixture of materials.

[0020] In addition, it should be noted that the self-made glue made by mixing polycarbonate and methyl ethyl ketone can only bond polycarbonate products. T...

Embodiment 2

[0026] The self-made glue provided in the second embodiment includes: granular injection molding raw materials and methyl ethyl ketone, wherein the mass fraction of granular injection molding raw materials is 13%, the mass fraction of methyl ethyl ketone is 87%, and the granular Granular injection molding raw materials and methyl ethyl ketone are mixed according to their respective mass fractions, and the final mixture of granular injection molding raw materials and methyl ethyl ketone is in a fluid state.

Embodiment 3

[0028] The self-made glue provided in the second embodiment includes: granular injection molding raw materials and methyl ethyl ketone, wherein the mass fraction of granular injection molding raw materials is 16%, the mass fraction of methyl ethyl ketone is 84%, and the granular Granular injection molding raw materials and methyl ethyl ketone are mixed according to their respective mass fractions, and the final mixture of granular injection molding raw materials and methyl ethyl ketone is in a fluid state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com