Device for rapidly assembling stud

A double-ended stud, fast technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of unstable installation and low work efficiency, and achieve the effects of reducing labor intensity of workers, high assembly efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

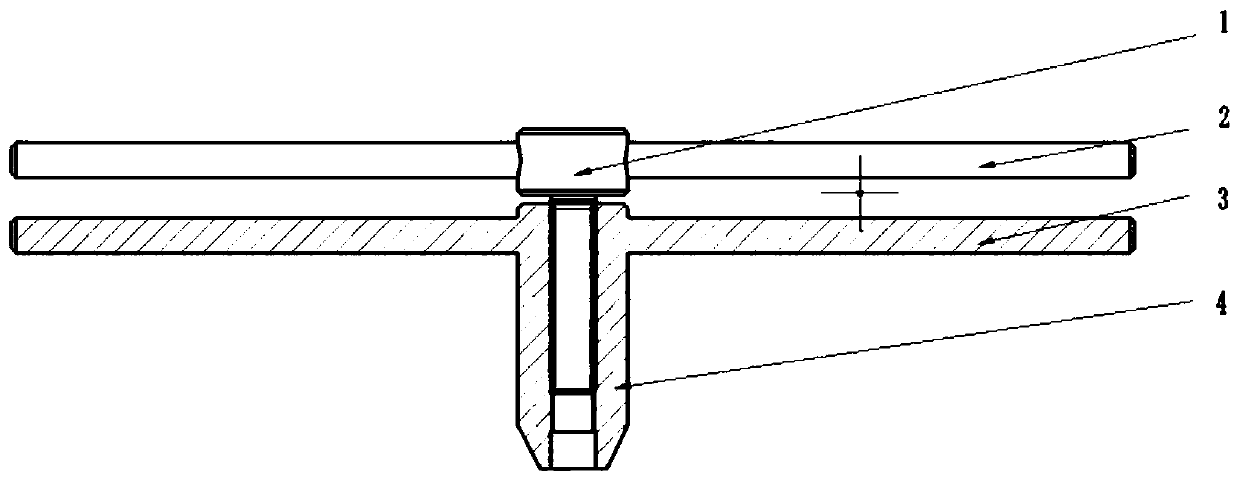

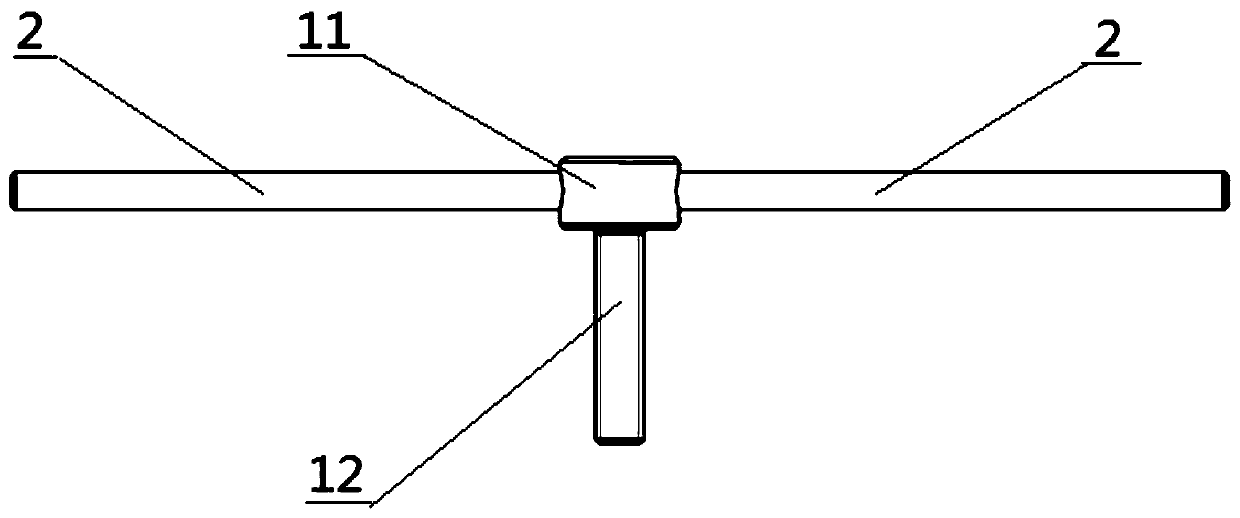

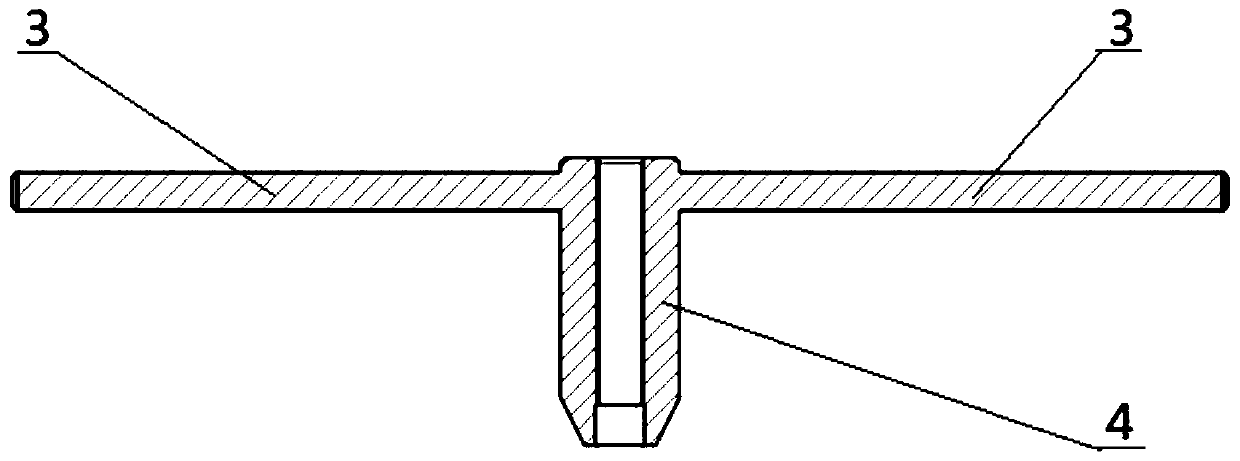

[0016] A device for quick assembly of double-ended studs, characterized in that it includes a threaded mandrel 1, an internal threaded sleeve 4, a first crossbar 2 and two second crossbars 3, and the threaded mandrel 1 includes a rod head 11 and an externally threaded rod body 12, the top of the threaded mandrel 1 is a rod head 11, and the externally threaded rod body 12 is connected below the rod head 11; there is a horizontal through hole on the rod head 11, and the first cross bar 2 passes through the through hole, And the middle part of the first cross bar 2 is fixed in the horizontal through hole on the rod head 11; Cooperating internal thread, the left and right symmetrical positions on the upper part of the outer wall of the internal thread sleeve 4, each fixedly connected with a second cross bar 3; Inside the sleeve 4.

[0017] The rod head 11 is a cylinder whose diameter is larger than that of the externally threaded rod body 12 .

[0018] The rod head 11 is a squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com