A clean and efficient preparation method of bio-based glycerol ketal acrylate reactive diluent

A technology of glycerol ketal acrylate and active diluent is applied in the field of clean and efficient preparation of bio-based glycerol ketal acrylate active diluent, which can solve the problems of incomplete reversible dehydration, affecting the conversion rate of raw materials, etc. Effects of safety and relatively high cost of investment, increased complexity, improved environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

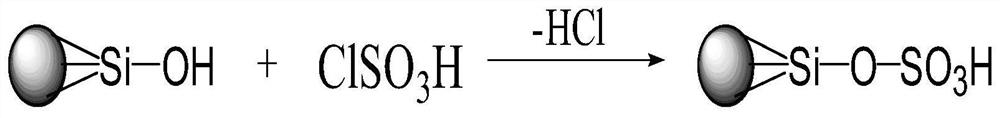

[0037] The second solid acid catalyst ZSM-SO 3 Preparation of H: The carrier ZSM-5 with silanol on the surface is first treated with dilute hydrochloric acid. The treatment process is: soak the carrier in a hydrochloric acid solution with a mass fraction of 10% for 24 hours, filter and then vacuum dry at 120°C After 6 hours, 5 g of the acid-treated carrier was dispersed in 100 mL of absolute ethanol, 11.2 mL of chlorosulfonic acid was added dropwise under stirring, and the reaction was carried out at room temperature for 50 min to obtain the sulfonic acid group bonded on the surface of the carrier. The second solid acid catalyst ZSM-SO 3 H. stand-by.

[0038] The second solid acid catalyst SiO 2 -SO 3 Preparation of H: Carrier SiO with silanol on the surface 2 Dilute hydrochloric acid treatment is carried out first, and the treatment process is: soak the carrier in a hydrochloric acid solution with a mass fraction of 10% for 24 hours, filter and then vacuum-dry at 120°C f...

Embodiment 2

[0040]

[0041] The R of the ketone compound shown in the formula II structure in this embodiment 1 and R 2 Both are methyl, that is, the ketone compound is acetone, and catalyzed condensation reaction---preparation of condensation product:

[0042] Add 504 grams of glycerin and 350 grams of acetone into a 1-liter four-necked reaction flask, and continue to add 30 grams of the first solid acid catalyst HY molecular sieve and 5 grams of sodium polyacrylate polymer resin water-absorbing agent wrapped by an oil-water separation cloth film during the stirring process The resulting dehydration bag is 1, and nitrogen gas is introduced from the bottom of the reaction bottle to take away the dissolved gas of the system, and the temperature is raised to 50°C for catalytic condensation reaction, and the reaction process is tracked by silica gel thin-layer chromatography. The process replaced 4 above-mentioned identical dehydration bags until the glycerol was completely converted, an...

Embodiment 3

[0046]

[0047] The R of the ketone compound shown in the formula II structure in this embodiment 1 and R 2 Constitute cyclohexyl, that is, the ketone compound is cyclohexanone, catalyzed condensation reaction——preparation of condensation product:

[0048] Add 400 grams of glycerin and 470 grams of cyclohexanone into a 1-liter four-necked reaction flask, and continue to add 40 grams of the first solid acid catalyst with a silicon-aluminum ratio of 50 HZSM-5 molecular sieves and wrap 5 grams of it with an oil-water separation cloth membrane while stirring. One dehydration bag made of sodium polyacrylate polymer resin water-absorbing agent. Nitrogen gas is introduced from the bottom of the reaction bottle to take away the dissolved gas in the system, and the temperature is raised to 90°C for catalytic condensation reaction. Silica gel thin-layer chromatography tracks the reaction process. During the reaction process, five of the same dehydration bags were replaced according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com