Tungsten enhancement copper composite and preparing method thereof

A composite material and copper powder technology, which is applied in the preparation of tungsten reinforced copper composite materials and the field of tungsten reinforced copper composite materials, can solve the problems such as the inability to form a network interconnection structure, the difficulty of maintaining the skeleton phase of tungsten, and the difficulty of metallurgical bonding of the tungsten phase. Achieve the effect of good practical value, precise and controllable size, and good conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of tungsten reinforced copper composite material, comprising the following steps:

[0043] Step 1, select raw materials

[0044] According to the volume fraction, weigh the following components, the copper powder is not less than 50%, the balance is tungsten powder, and the sum of the volume percentages of the above components is 100%;

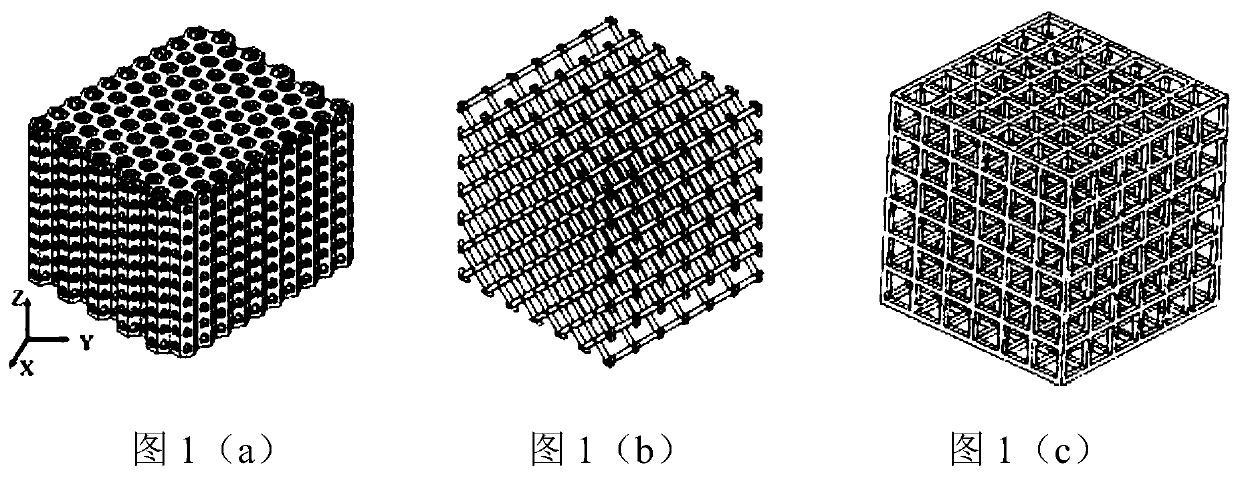

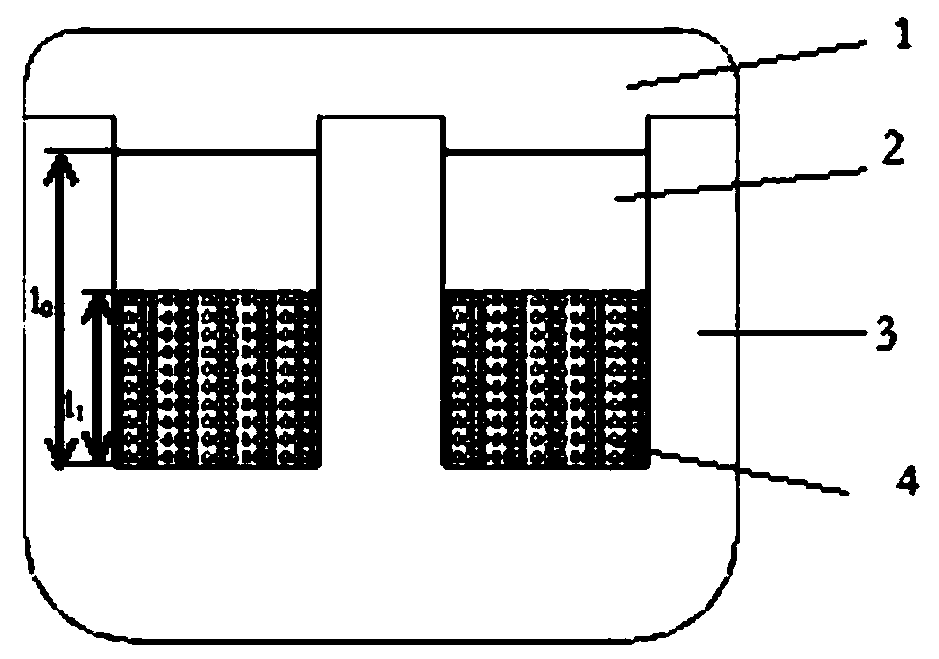

[0045] Step 2, preparing a porous tungsten skeleton;

[0046] Step 2.1, place the tungsten powder in step 1 in the powder loading chamber of the laser selective melting equipment, input the prefabricated porous tungsten skeleton model, start the laser selective melting equipment to print, the diameter of the spot is 45-100 μm, and the scanning method is checkerboard. One time of powder is selected by laser melting once, the scanning distance is 60μm, the scanning speed is 550-650mm / s, the thickness of the powder layer is 25μm, the laser power is 70W-100W, and the laser energy is 80-130J / mm 3 , continuous inert gas...

Embodiment 1

[0062] Objective: To prepare anisotropic copper-tungsten composite material, wherein the volume ratio of Cu is 60vol.%, and the volume ratio of W powder is 40vol.%.

[0063] Step 1, select raw materials

[0064] According to the volume fraction, weigh the following components, copper powder 60vol.%, the balance is tungsten powder, the particle size of pure tungsten powder is 15-53 μm, and the sum of the volume percentages of the above components is 100%;

[0065] Step 2, preparing a porous tungsten skeleton;

[0066] Step 2.1, place the tungsten powder in step 1 in the powder bin of the laser selective melting equipment, try to keep the upper surface of the powder in the bin as flat as possible, input the prefabricated porous tungsten skeleton model, and start the laser selective melting equipment to print, the spot diameter is 100 μm , the scanning method is checkerboard, every time the powder is laid, the laser selection is melted once, the scanning distance is 60μm, the sc...

Embodiment 2

[0079] Objective: To prepare anisotropic copper-tungsten composite material, wherein the volume ratio of Cu is 90vol.%, and the volume ratio of W powder is 10vol.%.

[0080] Step 1, select raw materials

[0081] According to the volume fraction, weigh the following components, the volume ratio of copper powder Cu is 90vol.%, the balance is tungsten powder, and the sum of the volume percentages of the above components is 100%;

[0082] Step 2, preparing a porous tungsten skeleton;

[0083] Step 2.1, place the tungsten powder in step 1 in the powder loading bin of the laser selective melting equipment, input the prefabricated porous tungsten skeleton model, start the laser selective melting equipment to print, the diameter of the spot is 80 μm, the scanning method is checkerboard, and the powder is laid once The laser selects melting once, the scanning distance is 60μm, the scanning speed is 600mm / s, the thickness of the powder layer is 25μm, the laser power is 100W, and the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com