Spraying device for architectural decoration

A technology for spraying equipment and architectural decoration, which can be used in spraying equipment, construction, and equipment for coating liquid on surfaces, etc., and can solve problems such as long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

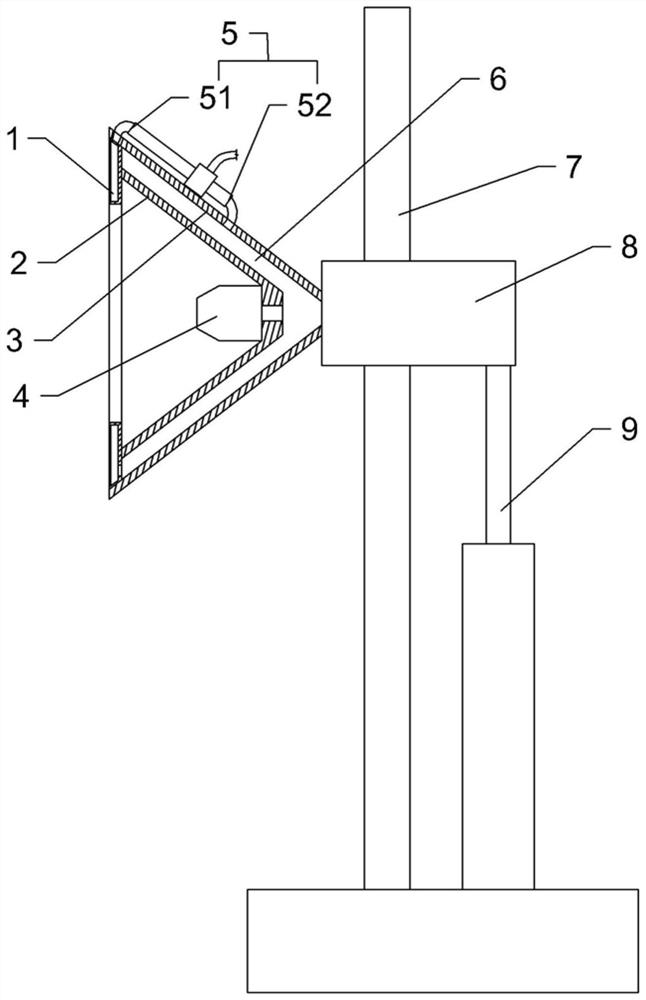

[0019] Embodiment one: if figure 1 Shown: the spraying device for architectural decoration, including a bracket 7, the bottom of the bracket 7 is rotatably connected with rollers for walking, the bracket 7 is vertically slid and connected with a slider 8, between the slider 8 and the bottom of the bracket 7 A telescopic mechanism is connected, and the telescopic mechanism is preferably a cylinder 9 in this embodiment, and the cylinder 9 is arranged vertically, the lower end of the cylinder 9 is hinged with the bottom of the support 7, and the upper end of the cylinder 9 is hinged with the slider 8. The slide block 8 is connected with a spray head 4 whose spraying direction is transverse, and the spray head 4 is connected with a paint supply pipe. The outer side of the nozzle 4 is covered with a first cover 2, the first cover 2 is conical, the axis of the first cover 2 is parallel to the spraying direction of the nozzle 4, the small diameter end of the first cover 2 is in conta...

Embodiment 2

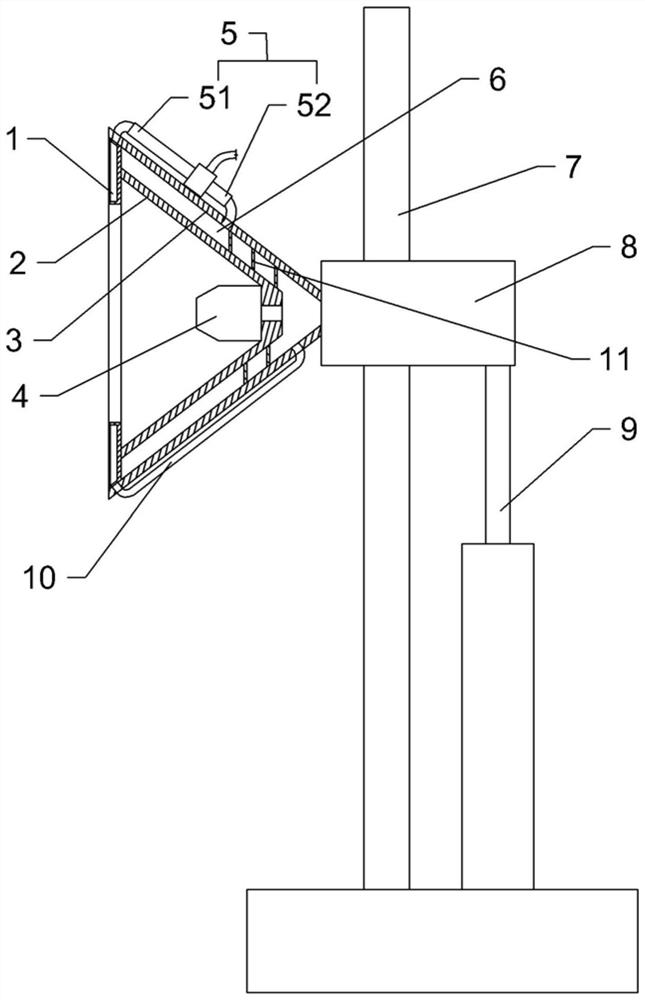

[0022] Embodiment two: the difference with embodiment one is only: as figure 2 As shown, a spiral partition 11 is installed in the cavity 6, the inner edge of the spiral partition 11 is welded and fixed with the first cover body 2, and the outer edge of the spiral partition 11 is against the second cover body 3, so that the spiral partition 11 divides the cavity 6 into a spiral channel; the air outlet of the heat pipe 1 communicates with the position near the nozzle 4 in the cavity 6 through the communication pipe 10, so that the air in the heat pipe 1 can quickly reach the position of the nozzle 4.

[0023] A helical channel is formed in the cavity 6 by the spiral partition 11, so that the cold air discharged from the cold end air outlet 52 of the vortex tube 5 enters the cavity 6 and flows in the helical channel, thus prolonging the cooling time. The flow path in the cavity 6 enables the cold air to exchange heat with the second cover body 3, and the first cover body 2 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com