Pressure-bearing detection device for civil mechanical test

A technology of civil mechanics and testing device, applied in measuring device, using stable tension/pressure to test material strength, scientific instruments, etc. Normal use, replacement and other issues, to avoid damage to the display screen, avoid error detection data, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

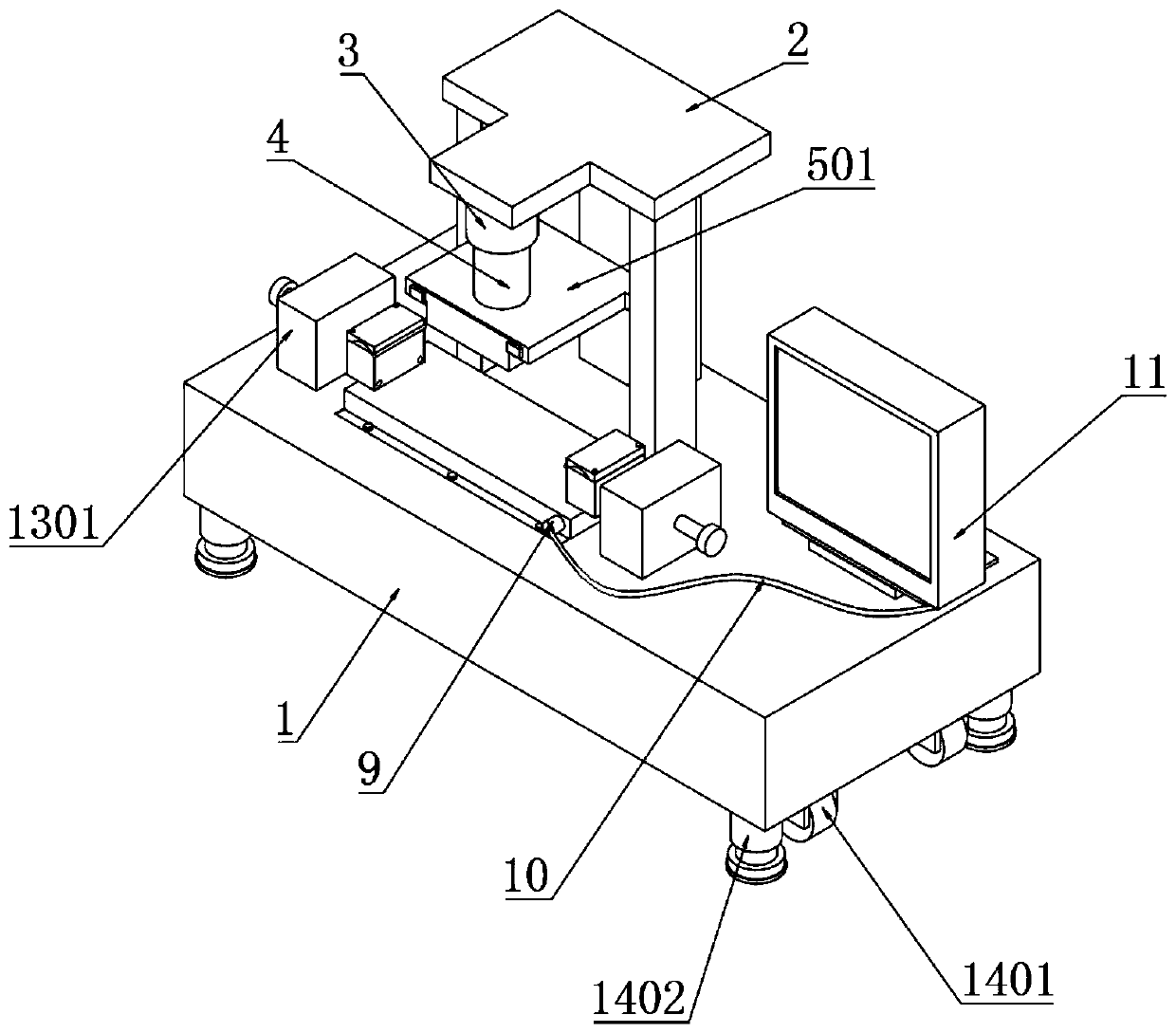

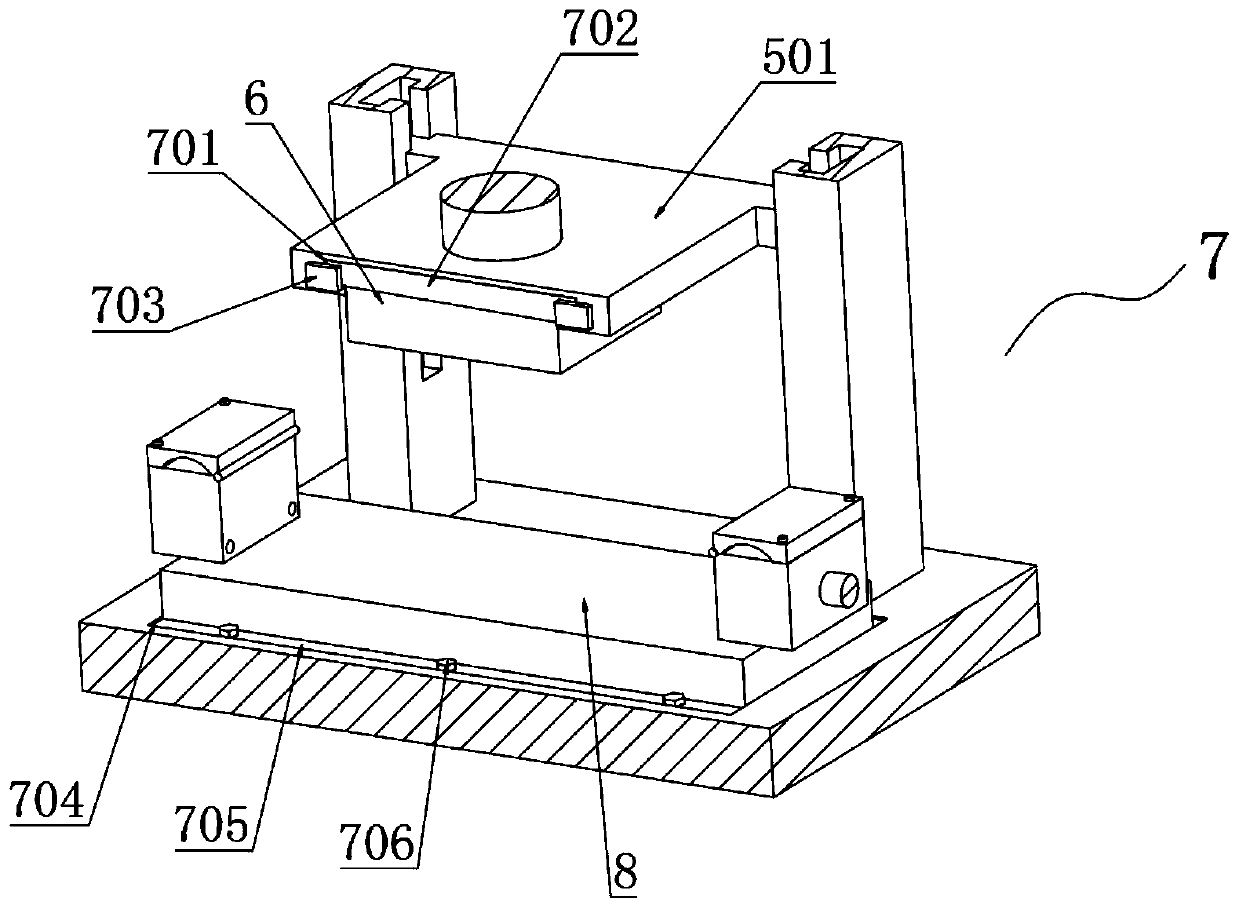

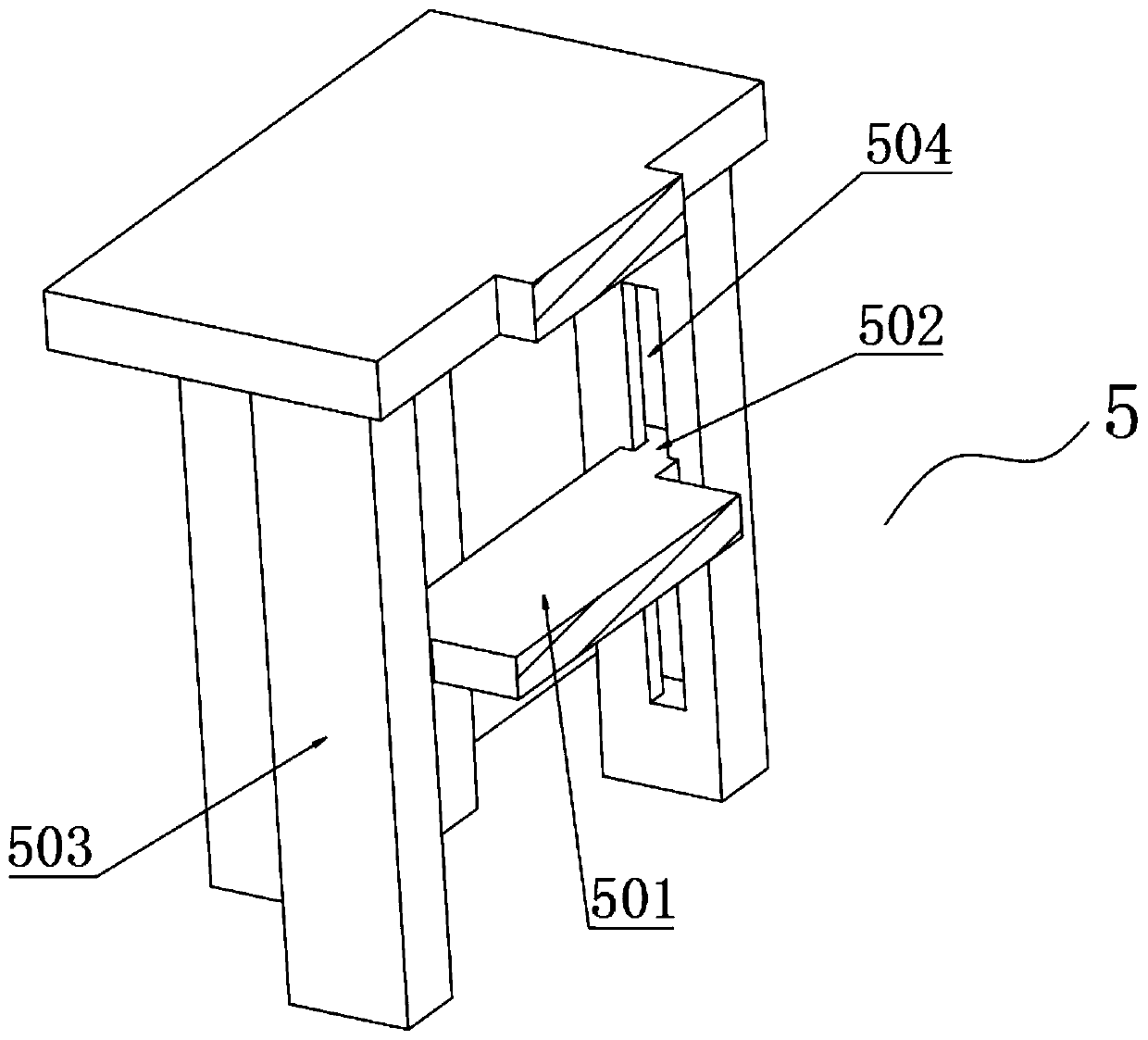

[0050] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a pressure detection device for civil mechanics tests, comprising:

[0051] The positioning mechanism 5 is used to position the upper pressing block, so as to avoid the position deviation of the upper pressing block during the traveling process, resulting in uneven pressure on the detection object;

[0052] The installation mechanism 7 is used to install and fix the upper pressure block and the pressure bearing plate, so as to facilitate the replacement of the upper pressure block and the pressure bearing plate;

[0053] Steering mechanism 12 is used to rotate and change the direction of the display screen, so as to facilitate observation of the data displayed on the display screen;

[0054] The clamping mechanism 13 is used for clamping the detection object, avoiding the position deviation of the detection object during the detection process, and improving the accuracy of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com