Wiring board and electrical equipment

A technology of wiring boards and wiring segments, applied in the directions of electrical components, circuits, connections, etc., can solve the problems of extrusion and cracking of the base body, bolt out, and damage to the wiring board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

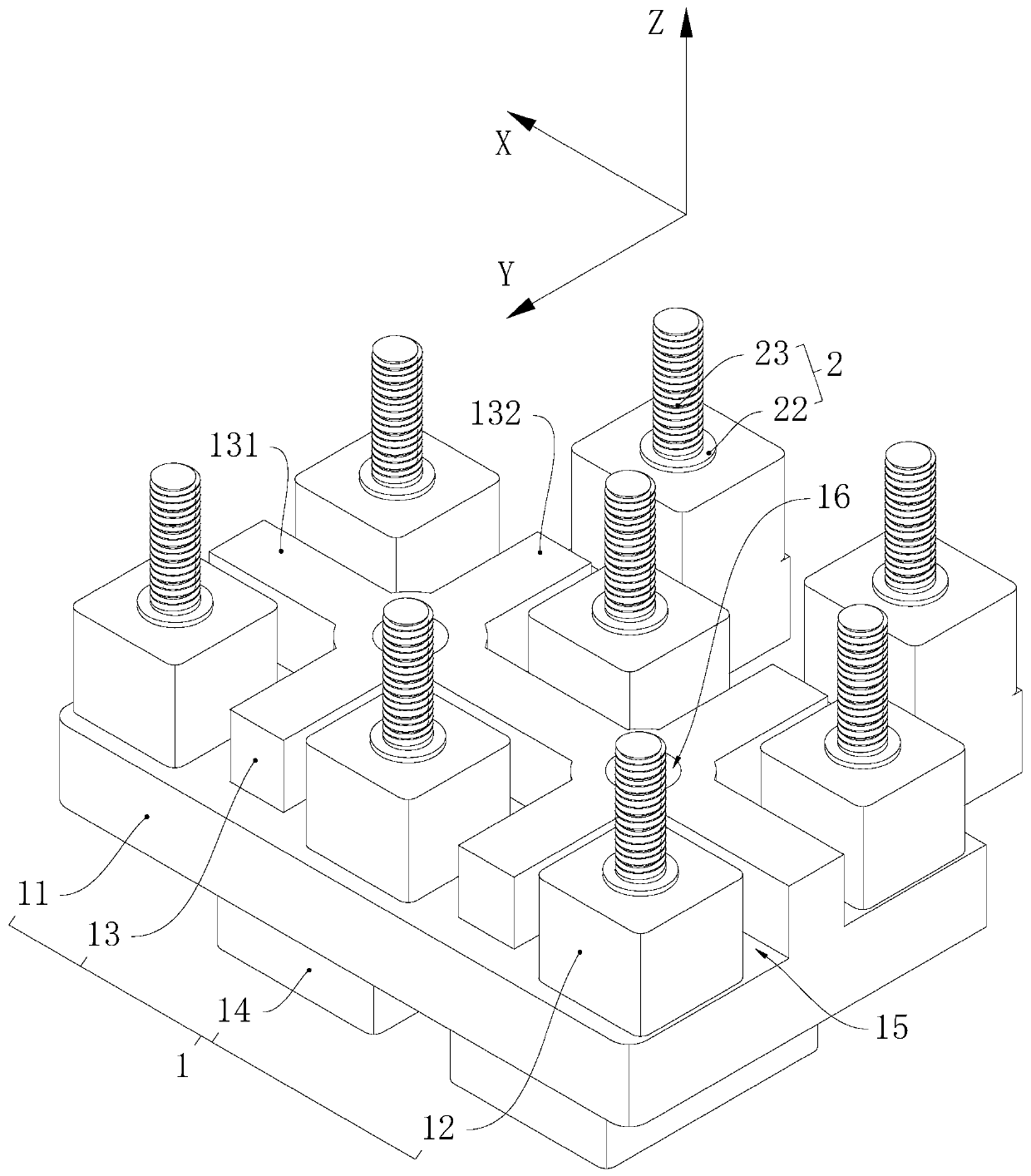

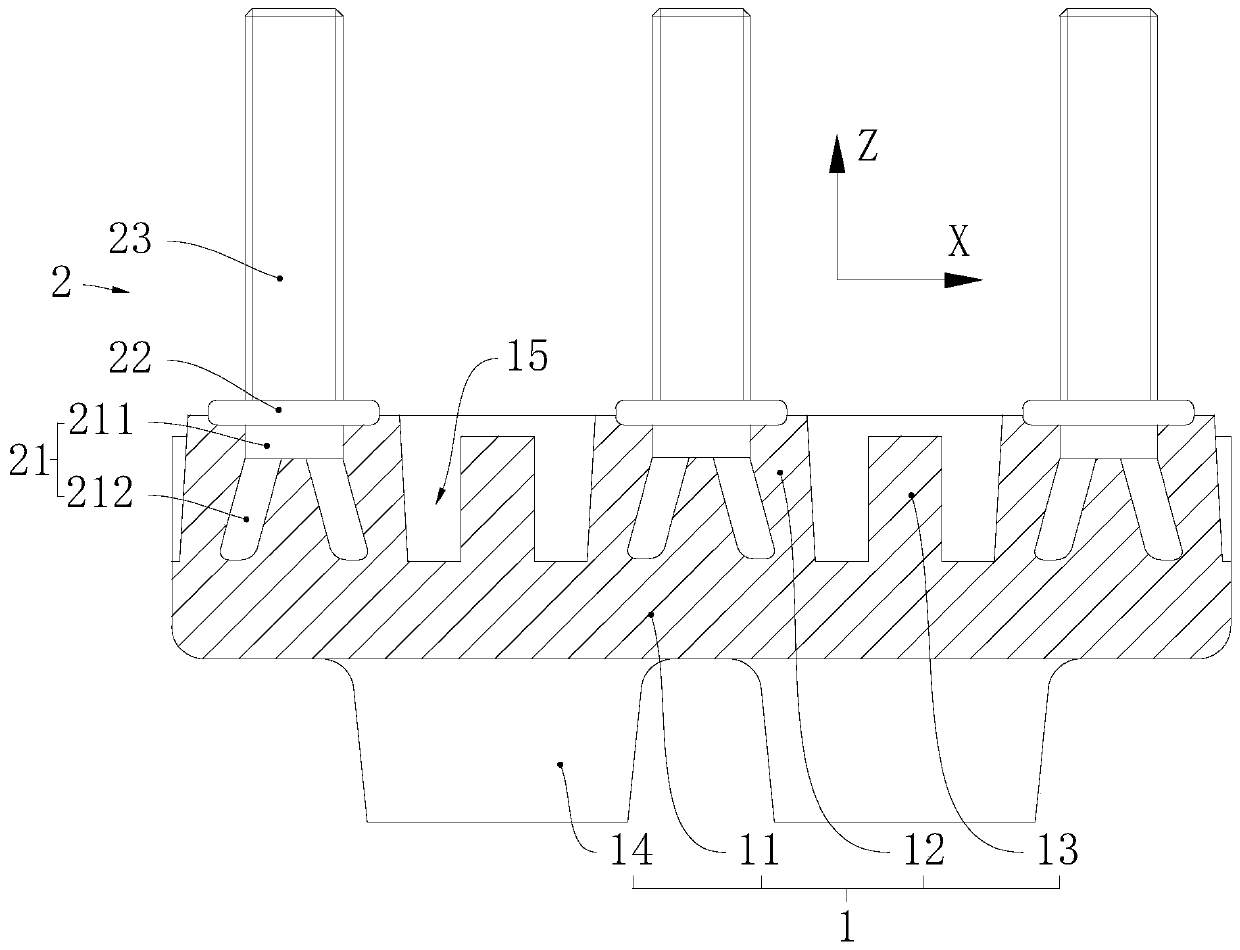

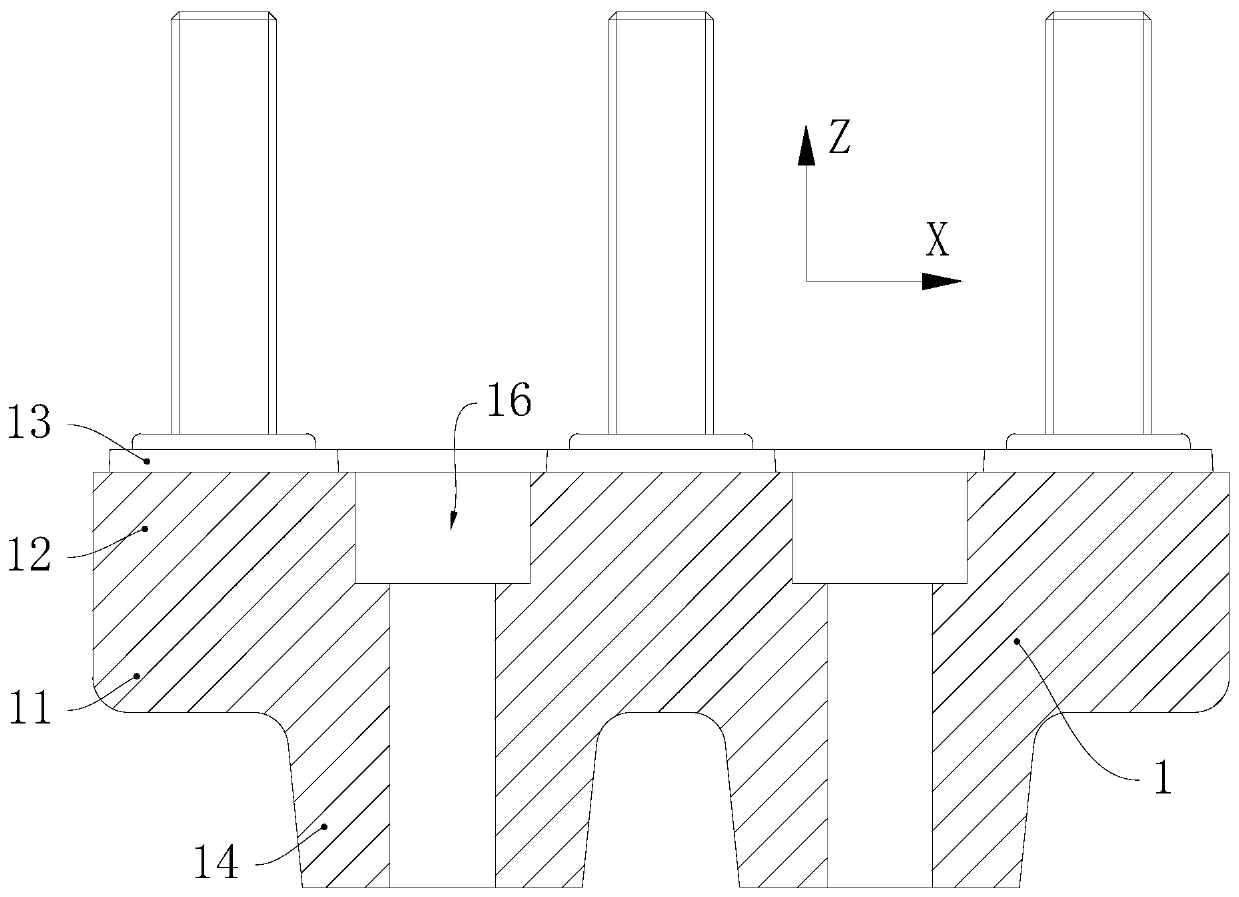

[0030] Terminal board example:

[0031] This example refers to figure 1 The space Cartesian coordinate system shown indicates the positional relationship of each component in the wiring board, please refer to Figure 1 to Figure 4 , the wiring board of this embodiment includes a base body 1 and a terminal post 2, the base body 1 is injection molded by bulk molding compound (BulkMolding Compound, BMC), the terminal post 2 is a metal guide post, and the terminal post 2 has a fixed section 21, a fixed gasket 22 and wiring section 23, the fixing section 21, the fixing gasket 22 and the wiring section 23 are sequentially connected along the positive direction of the Z axis, the fixing section 21 is embedded in the base body 1, the wiring section 23 has threads, and the fixing gasket 22 and the wiring section 23 are both Exposed outside the substrate 1.

[0032] The base 1 has a base 11 , a first boss 12 , a second boss 13 and a third boss 14 , and the first boss 12 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com