High-safety hot-plug low-voltage power supply interface

A low-voltage power supply, high-security technology, applied in circuits, connections, electrical components, etc., can solve problems such as poor power supply interface security, and achieve the effects of less pollution, improved safety, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

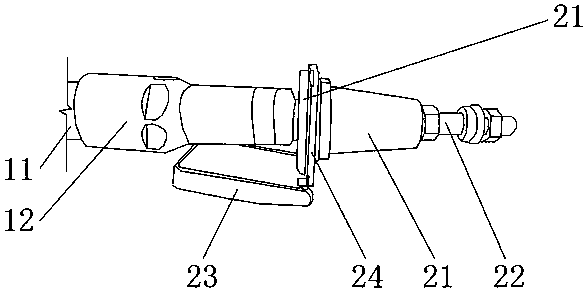

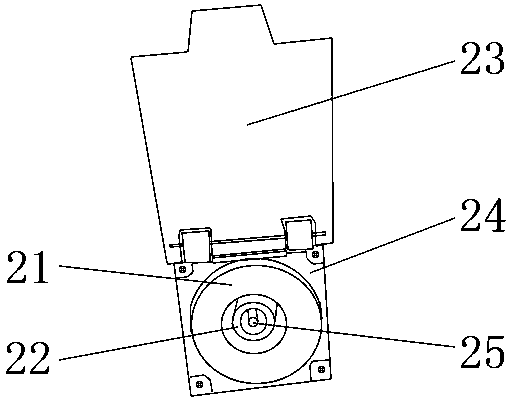

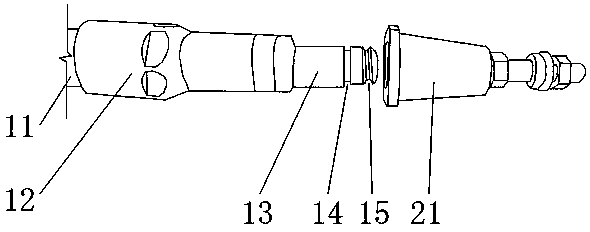

[0023] A high-safety hot-swappable low-voltage power supply interface, installed on the housing of the power supply equipment, such as figure 1 As shown, this embodiment includes a hot-swappable plug and a socket. The hot-swappable plug includes an insulating sleeve 12, metal contacts and outgoing wires 11, and the metal contacts are connected to the outgoing wires 11. The metal contacts and the outgoing wires 11 are installed on On the insulating sleeve 12, the socket includes an insulating shell 21, a metal contact sleeve 22 and a stem 25. The front part of the metal contact sleeve 22 is processed with a contact cavity for accommodating metal contacts. One end of the contact cavity is open and the other end is closed. The outer wall of the metal contact sleeve 22 is The insulating shell 21 is fixedly connected, the rear part of the metal contact sleeve 22 passes through the insulating shell 21, the second end of the stem 25 is fixedly connected to the closed end of the contac...

Embodiment 2

[0028] This embodiment is further improved on the basis of the first embodiment, and further improves the security of the power supply interface. Such as Figure 4 As shown, in this embodiment, the metal contact head 13 is processed with a charging locking groove 14, the metal contact sleeve 22 also includes a charging locking device, and the metal contact sleeve 22 is processed with a locking hole corresponding to the charging locking groove 14, The locking hole runs through the side wall of the metal contact sleeve 22, and the insulating shell 21 is processed with a cavity for accommodating the live locking device. The live locking device can be a signal relay or an electromagnet.

[0029] The live locking device includes a mounting ring 31, a spring 32, a pin 33, a pin cap 34, a magnetic ring 35, a resistor R1, a resistor R2, a capacitor C and a diode D1. The mounting ring 31 is concentric with the locking hole and is fixedly installed on the metal contact sleeve 22 On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com