A combined damping tool holder

A combined, arbor technology, used in boring bars, manufacturing tools, boring/drilling, etc., can solve the problems of low processing efficiency, complicated operation, weakened vibration reduction effect, etc., to improve processing efficiency and processing accuracy, Simple and convenient operation, enhanced vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

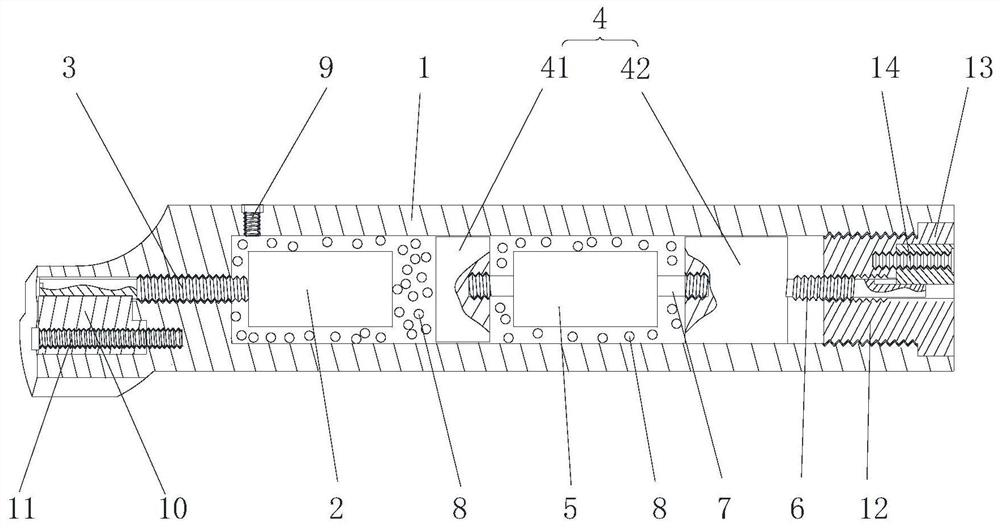

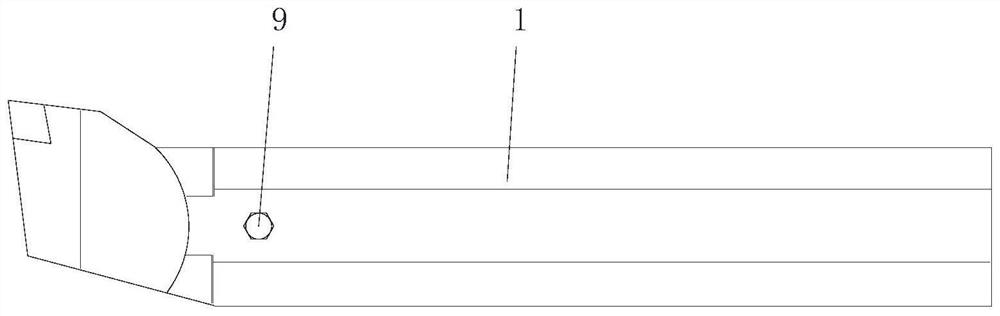

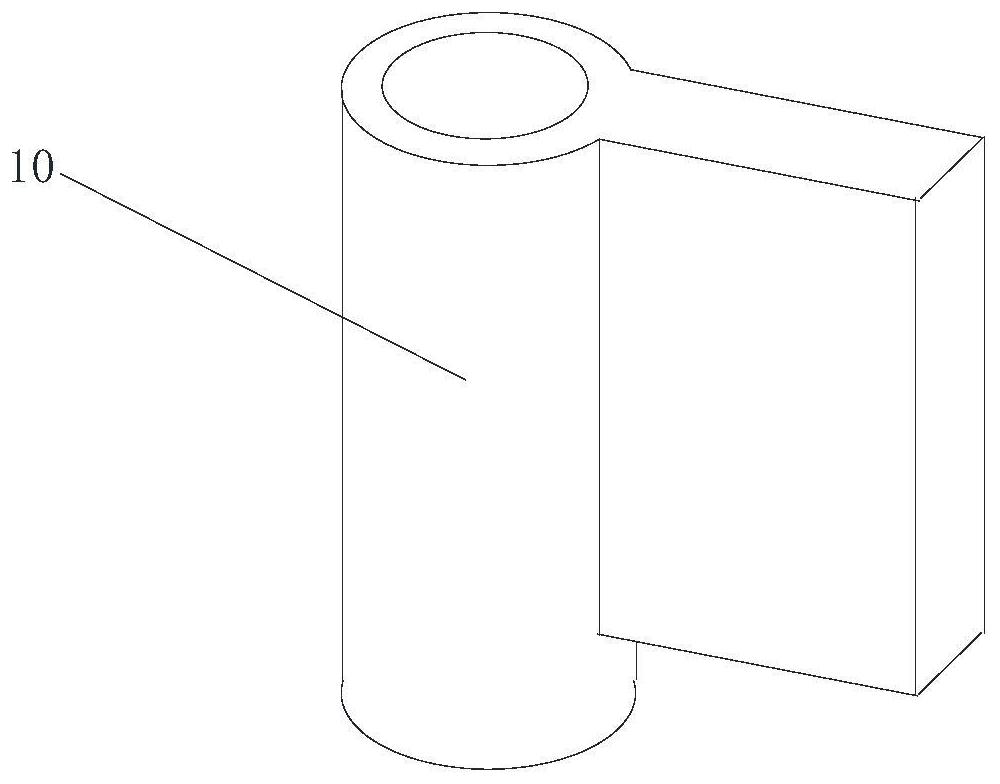

[0026] Figure 1 to Figure 4 It shows an embodiment of the combined damping tool holder of the present invention, including the tool holder body 1, the cantilever beam damping block 2, the cantilever beam rod 3, the slider 4, the simply supported beam damping block 5 and the adjustment rod 6 , the rear end surface of the cutter bar body 1 is provided with an inner cavity extending axially along the cutter bar. The first end of the rod 3 is connected to the cantilever beam damping block 2, the second end is connected to the front end of the axially adjustable cutter bar body 1, the slider 4 and the Charpy beam damping block 5 are connected through a connecting piece 7, and installed Set at the first end of the adjusting rod 6, the second end of the adjusting rod 6 can be axially adjusted and connected to the rear end of the tool bar b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com