Fixing device for robot maintenance

A technology of fixing devices and robots, which is applied in the direction of workpiece clamping devices, manipulators, manufacturing tools, etc., can solve the problems affecting the efficiency and quality of the inspection and maintenance of the rotating shaft, inconvenient access and storage of inspection tools, power cords and data lines falling off and other problems, to achieve the effect of stable transmission, strong lateral compression resistance, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

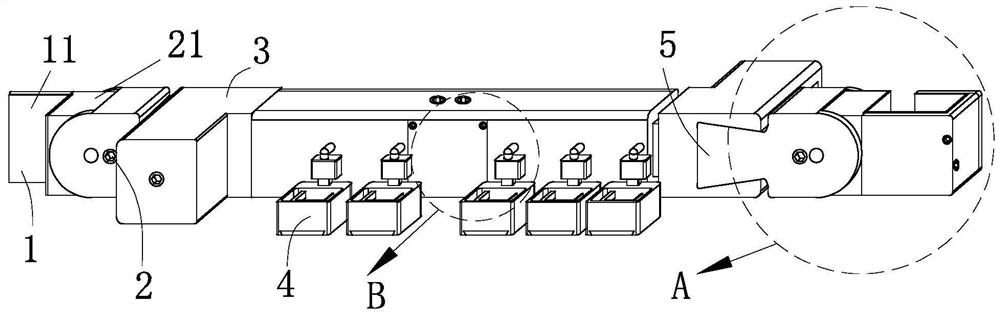

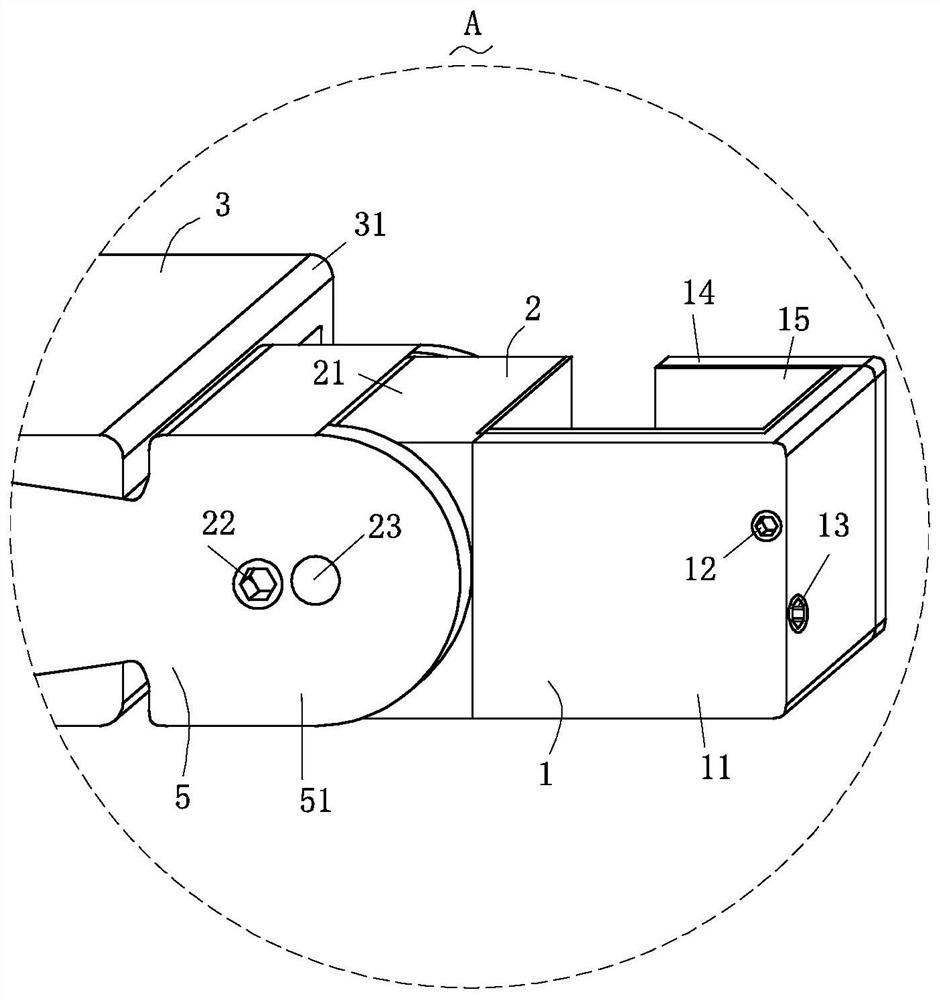

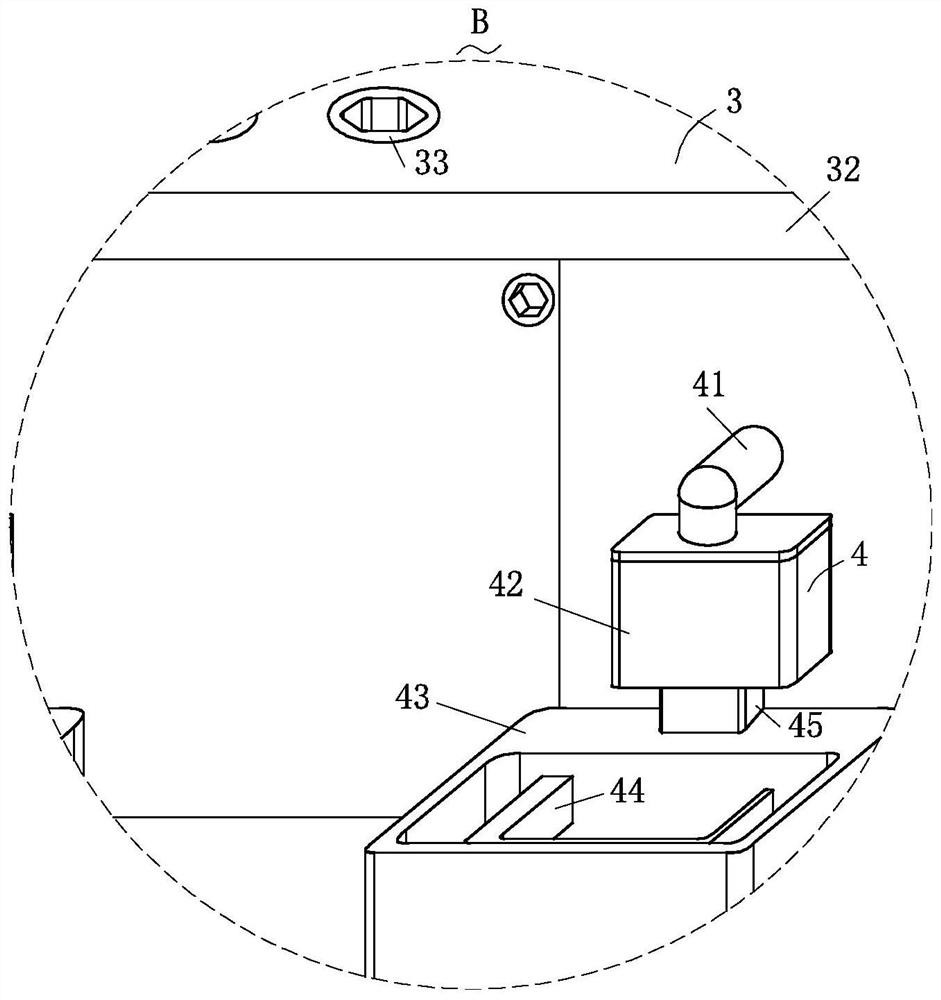

[0026] Such as Figure 1-Figure 7 As shown, a fixing device for robot maintenance according to the present invention includes a limit structure 1, an angle adjustment structure 2, a length adjustment structure 3, a storage structure 4 and a dislocation structure 5; the length for adjusting the limit length The two ends of the adjustment structure 3 are provided with the dislocation structure 5 for staggering the fixed position of the robot power arm, and the two dislocation structures 5 are diagonally symmetrically arranged with respect to the length adjustment structure 3; There is the angle adjustment structure 2 for adjusting the support angle, and the angle adjustment structure 2 is rotationally connected with the dislocation structure 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com