Connecting and separating device based on memory alloy wire driving

A technology for connecting and separating devices and memory alloy wires, which is applied in the aerospace field, can solve problems such as easy generation of redundant substances or polluted gases, poor safety of pyrotechnic devices, and non-repeatable detection, so as to reduce impact, facilitate repeated use, and ensure The effect of reliable separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

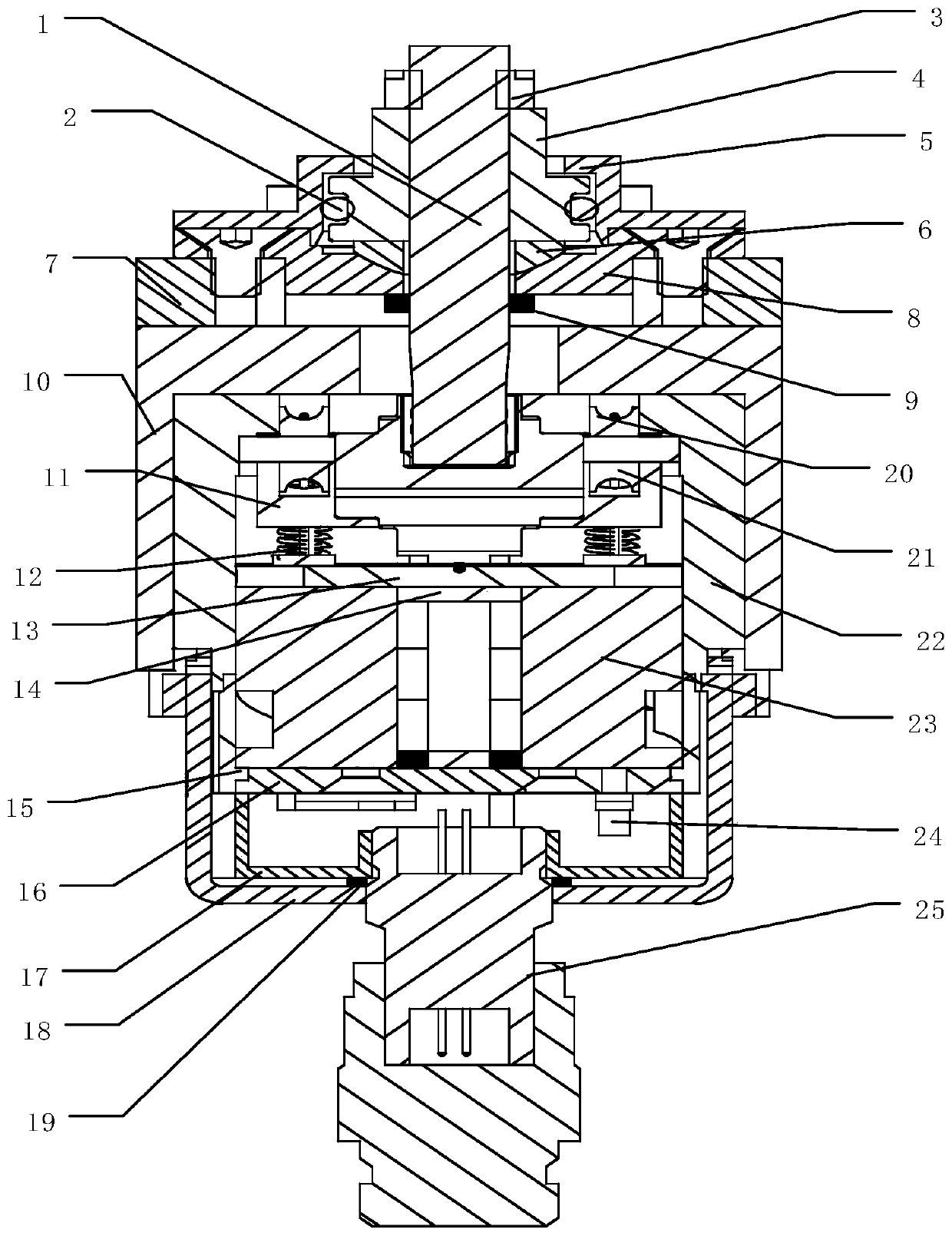

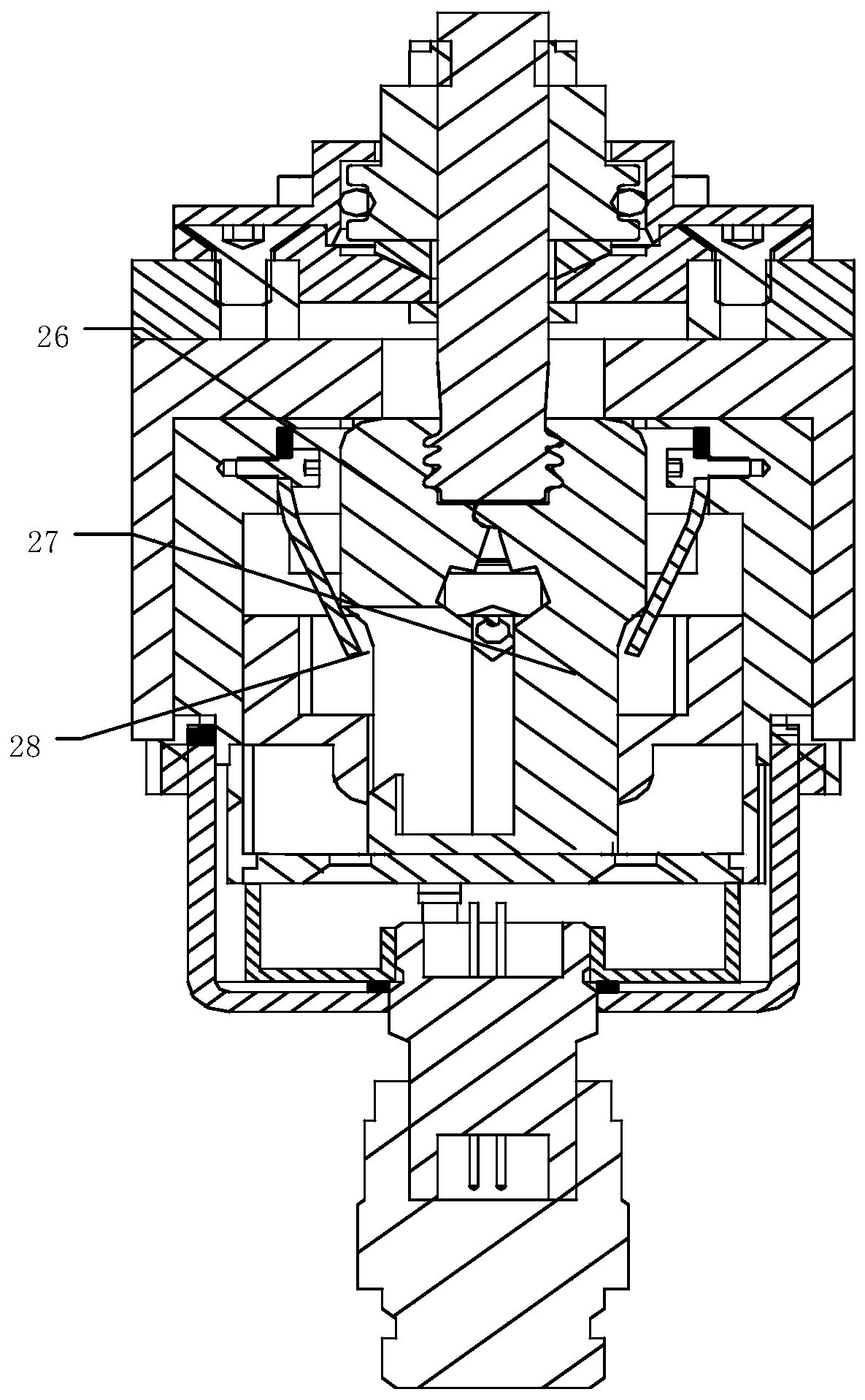

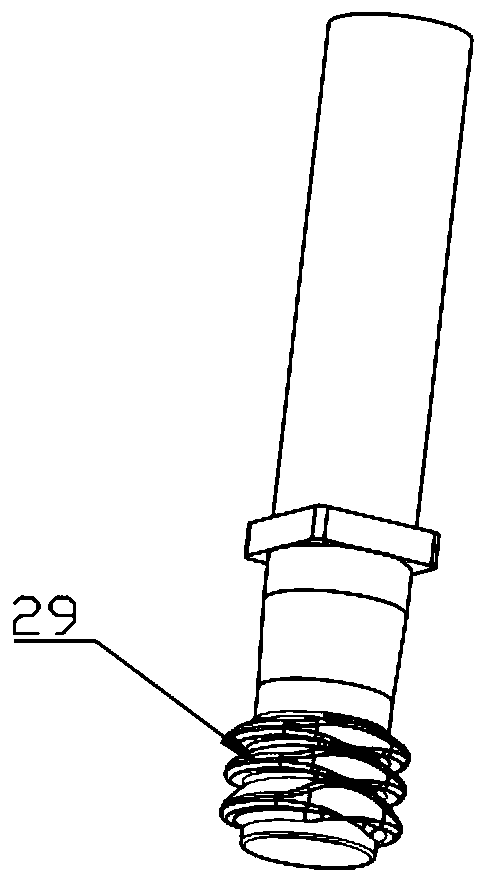

[0038] Such as Figure 1-Figure 7 As shown, a connection and separation device driven by a memory alloy wire includes an active end and a passive end. The active end passes through the housing 10, and the passive end is connected to the two systems respectively through the separator 7. The active end includes the housing 10. Overcoat 22, fixed piece 11, compression spring 12, rotary sleeve 15, base 16, memory alloy wire 20, guide wheel 21, lock pin 23, limit sleeve I26 and limit sleeve II27;

[0039] The outer casing 22 is coaxially fixed in the housing 10, the limiting sleeve I 26, the limiting sleeve II 27, the fixed piece 11, the guide wheel 21 and the lock pin 23 are all arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com