Steel structure high-altitude welding cage-type closed environment operation platform and using method thereof

An operating platform and closed environment technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of increased risk of high-altitude operations, difficulty in welding steel structures, etc., to improve project quality and safety Guarantee the effect, solve the risk problem of high-altitude operation, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

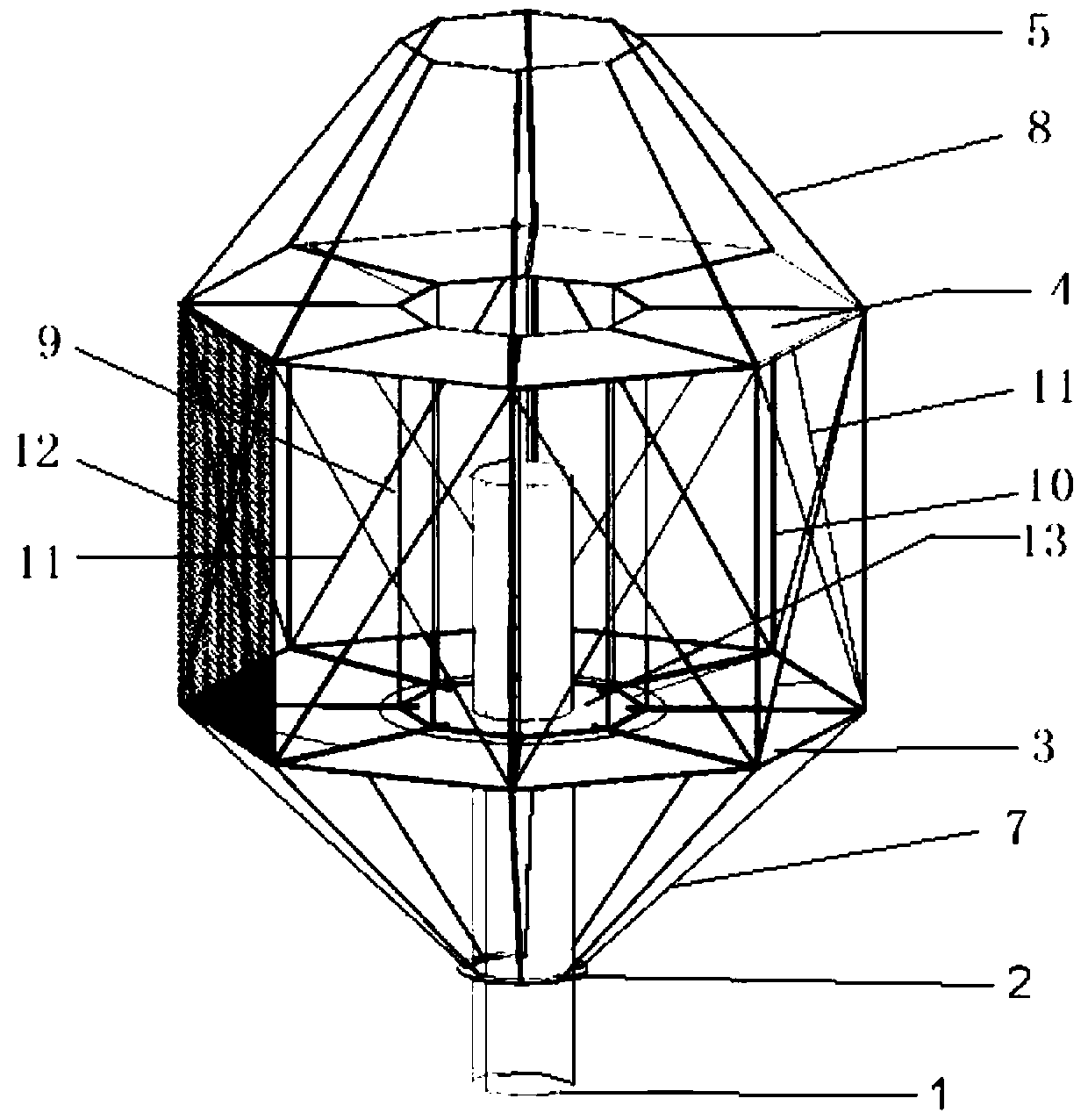

[0013] refer to figure 1 , the present embodiment provides a steel structure high-altitude welding cage-type closed environment operation platform and its use method, including a ring plate 2, a bottom ring platform 3, a top ring platform 4 and an inner collar 5, a ring plate 2, a bottom ring The annular platform 3, the top annular platform 4 and the inner collar 5 are sequentially set on the columnar steel structure 1 from bottom to top. The rods 7 are arranged at equal intervals along the circumference of the ring plate 2 and the bottom ring platform 3. The outer eaves of the top ring platform 4 and the inner collar 5 are fixedly connected by the upper slanting rod 8, and the upper slanting rod 8 is ring-shaped along the top. The circumferential equidistant distribution of the platform 4 and the inner collar 5 is arranged, the inner rings of the bottom annular platform 3 and the top annular platform 4 are fixedly connected by the inner vertical rod 9, and the outer rings of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com