A transformer temperature measurement system and measurement method

A temperature measurement and transformer technology, applied in the field of power transformer operation monitoring, can solve the problems of increasing error, the accuracy of calculation results cannot be guaranteed, and the calculation parameters cannot be matched, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

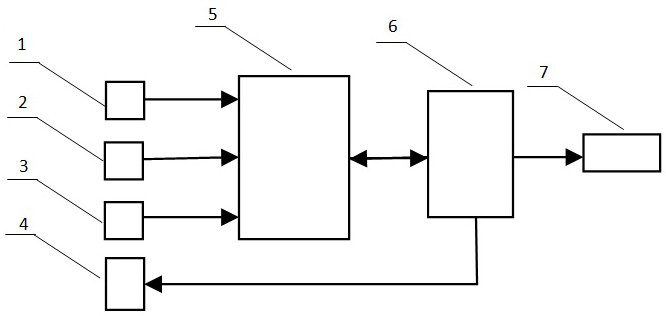

[0076] Refer to attached figure 1 , the realization scheme adopts technical scheme one.

[0077] Specific data of the measured transformer:

[0078] Product model: SFPSZ10-180000 / 220

[0079] Rated capacity: 180 / 180 / 90MVA

[0080] Rated current: 472 / 900 / 4950A

[0081] Cooling method: ODAF

[0082] The steady-state temperature rise data of the top layer oil temperature under the rated loss reported by the factory: 55K

[0083] Gradient data of hot spot temperature to top oil temperature at rated current: 10K

[0084] All four sets of radiators are configured and put into operation.

[0085] The transformer oil level temperature sensor 1 is placed in the temperature sensor installation slot on the top of the transformer, and is used to measure the oil level temperature inside the transformer. The sensor uses a Pt100 temperature sensor, which outputs a resistance signal that changes with temperature, and the output signal is connected to the transformer measurement and contr...

Embodiment 2

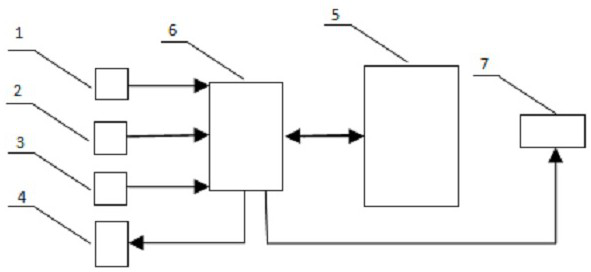

[0132] Refer to attached figure 2 , the realization scheme adopts the technical scheme two.

[0133] In the figure: transformer oil surface temperature sensor 1, transformer ambient temperature sensor 2, transformer cooling system operation sensor 3, transformer temperature local display unit 4, transformer substation automation system transformer measurement and control equipment 5, transformer temperature management unit 6, transformer temperature remote Display unit 7.

[0134] Specific data of the measured transformer:

[0135] Product model: SFPSZ10-180000 / 220

[0136] Rated capacity: 180 / 180 / 90MVA

[0137] Rated current: 472 / 900 / 4950A

[0138] Cooling method: ODAF

[0139] The steady-state temperature rise data of the top layer oil temperature under the rated loss reported by the factory: 55K

[0140] Gradient data of hot spot temperature to top oil temperature at rated current: 10K

[0141] All four sets of radiators are configured and put into operation.

[0142...

Embodiment 3

[0167] Refer to attached figure 2 , the realization scheme adopts the technical scheme two.

[0168] In the figure: transformer oil surface temperature sensor 1, transformer ambient temperature sensor 2, transformer cooling system operation sensor 3, transformer temperature local display unit 4, transformer substation automation system transformer measurement and control equipment 5, transformer temperature management unit 6, transformer temperature remote Display unit 7.

[0169] Specific data of the measured transformer:

[0170] Product model: SSZ10-50000 / 110

[0171] Rated capacity: 50MVA

[0172] Rated current: 262A

[0173] Cooling method: ONAN

[0174] The steady-state temperature rise data of the top layer oil temperature under the rated loss reported by the factory: 55K

[0175] Gradient data of hot spot temperature to top oil temperature at rated current: 10K

[0176] The transformer oil level temperature sensor 1 is placed in the temperature sensor installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com