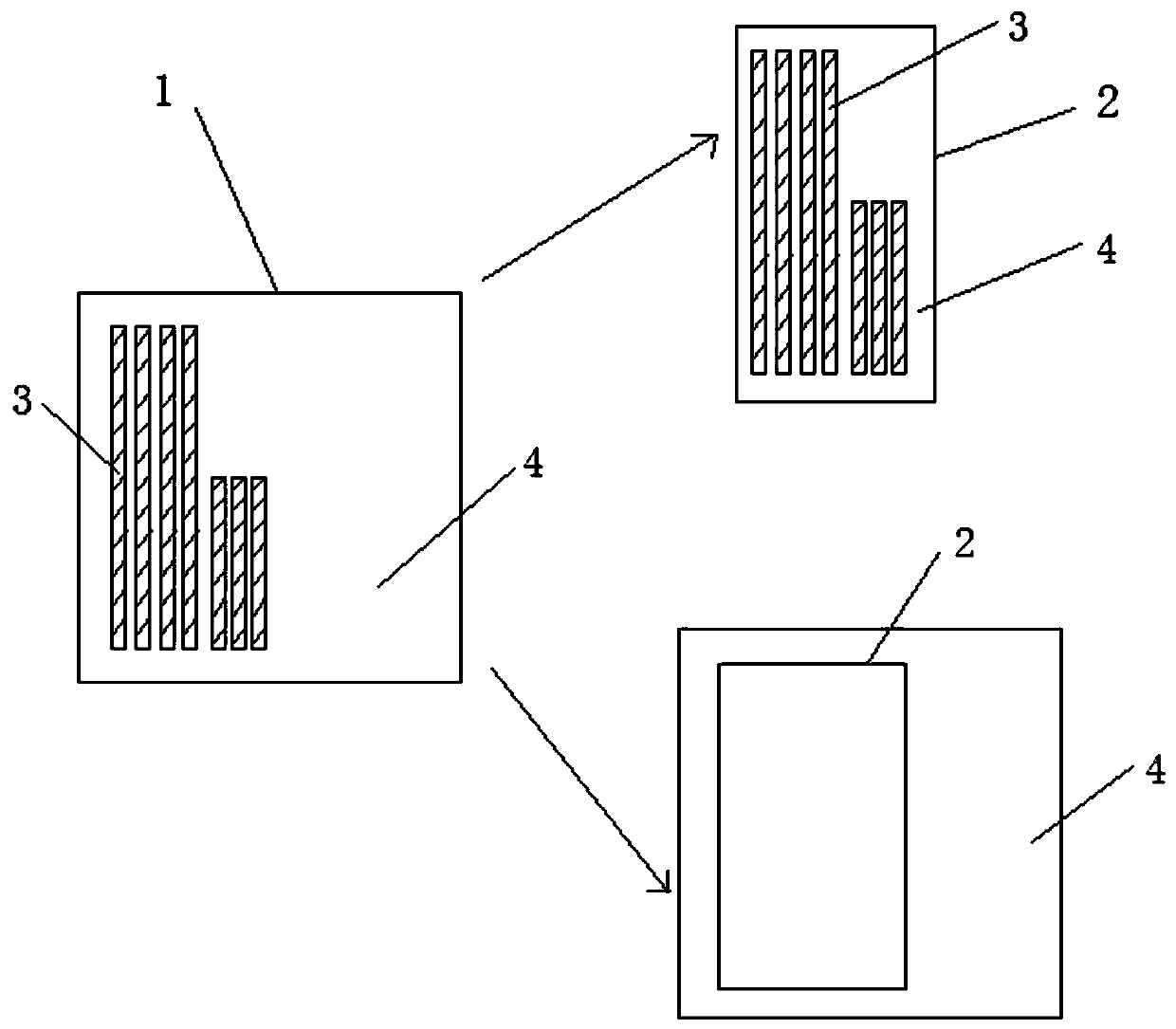

Wafer defect detection method and device

A defect detection and wafer technology, used in measurement devices, semiconductor/solid-state device testing/measurement, material analysis by optical means, etc., can solve the problem of providing optimal focal length conditions for different circuit layout areas, and cannot adapt to different at the same time. The focal length requirements of the circuit layout area, the difficulty of achieving simultaneous focus in different circuit layout areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0032] In the manufacturing process of semiconductor devices, the quality of photolithography is very important, which directly affects the performance, yield and reliability of devices. Generally, there are the following requirements for lithography: the obtained graphics have good integrity, accurate dimensions, neat edges, steep lines, no pinholes in the graphics, no small islands outside the graphics, no dyeing, clean substrate surface, no bottom film and graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com