Lamp fault detecting system

A technology for fault detection and lighting, applied in lighting testing, sorting and other directions, can solve the problems of long disassembly and assembly of lamps, labor consumption of workers, cumbersome detection methods, etc., to improve practicability, reliability, and stability. And the effect of firmness and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

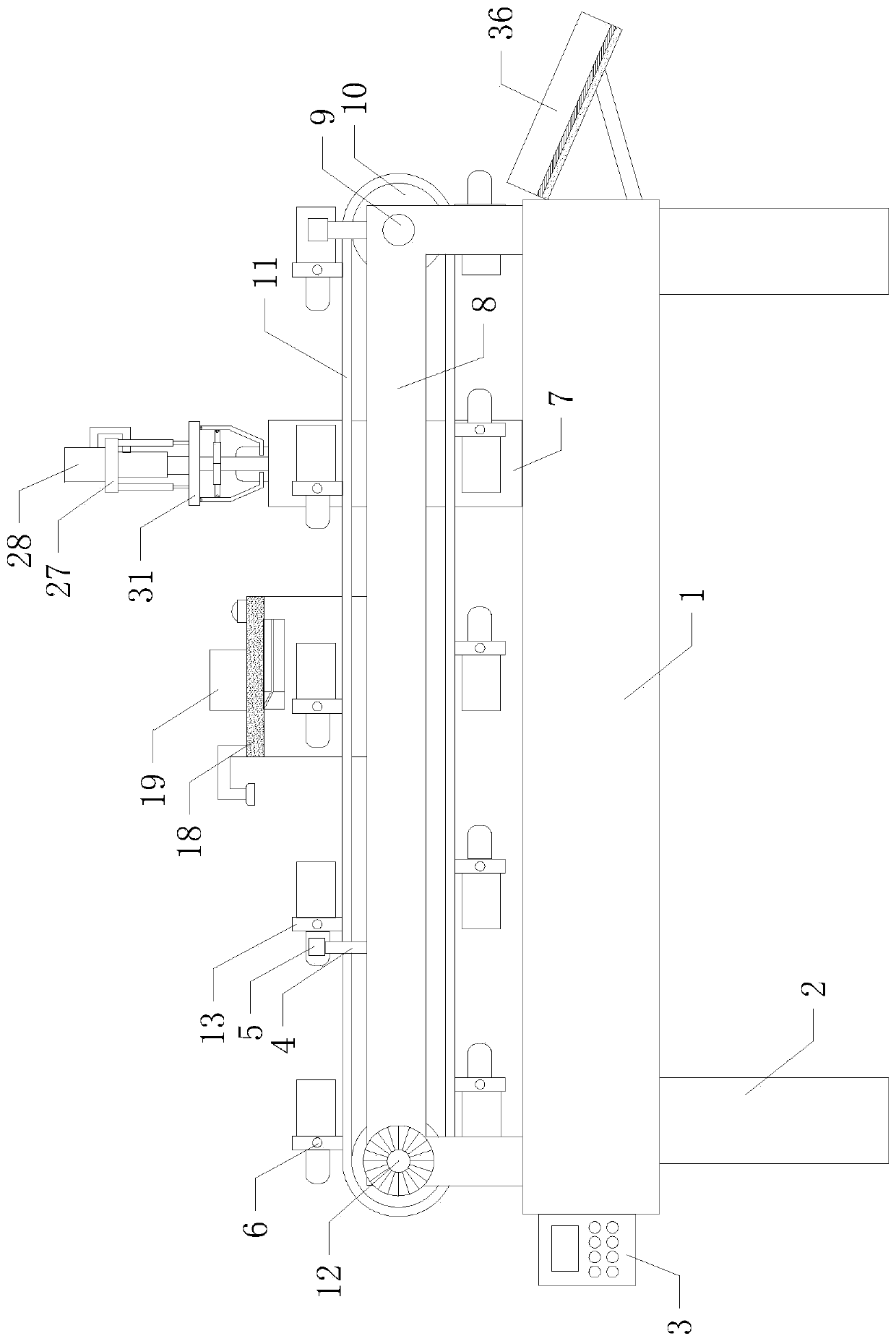

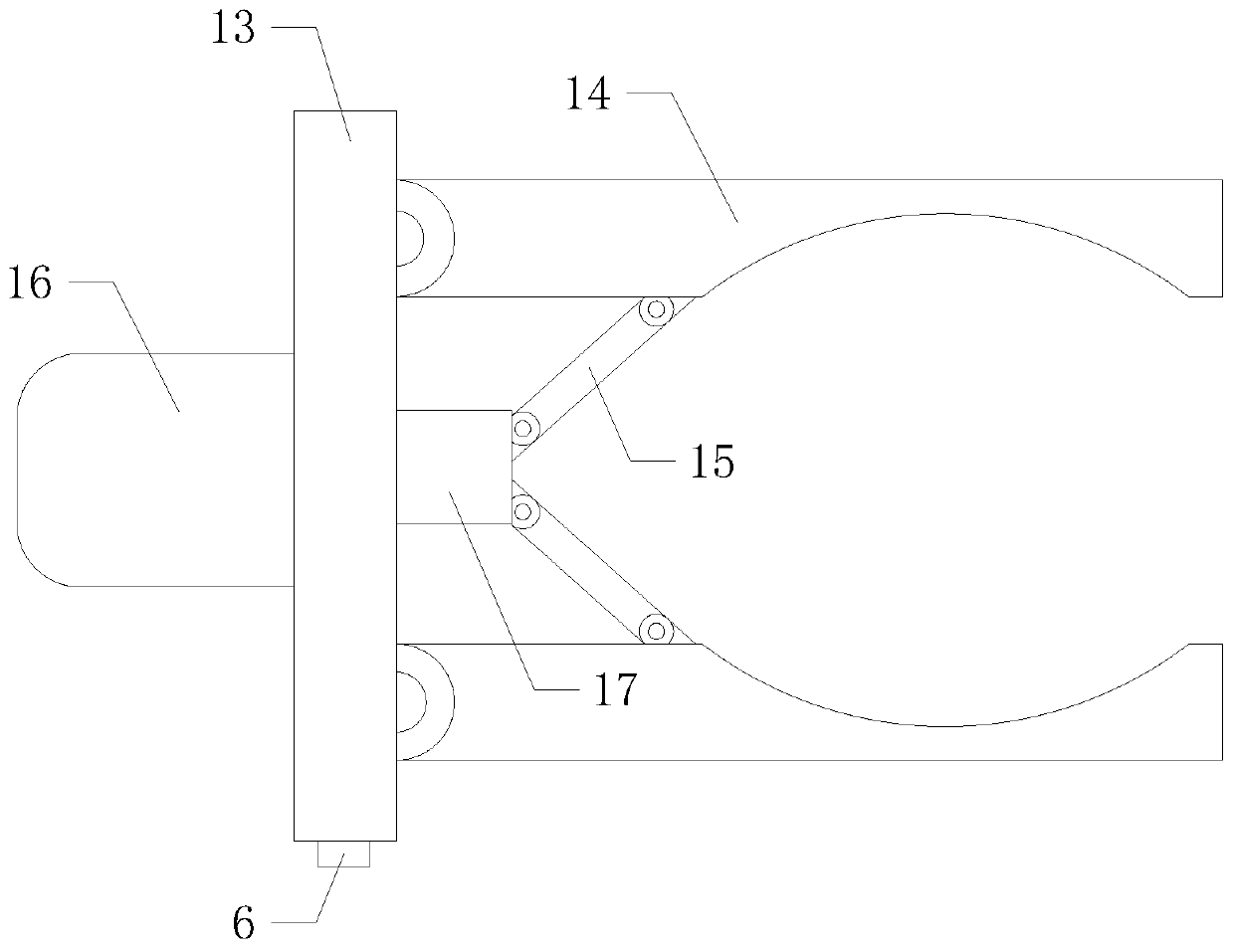

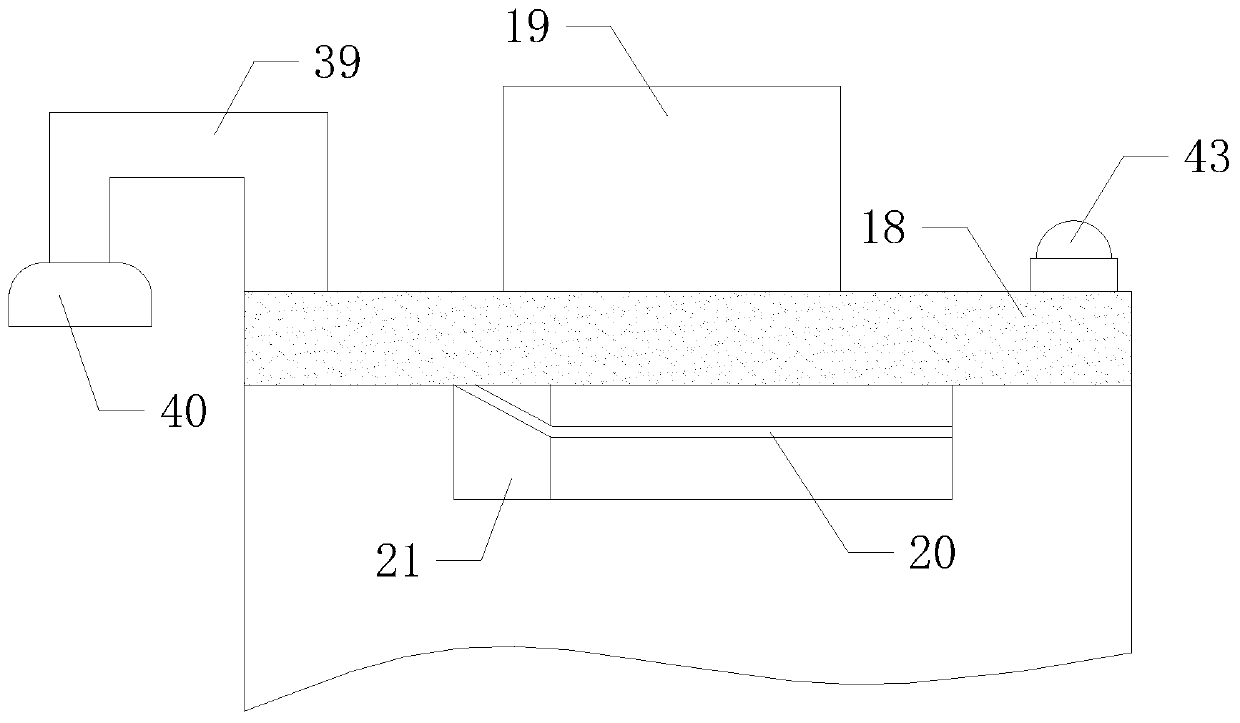

[0023] Such as Figure 1 to Figure 7 As shown, a lamp failure detection system of the present invention, when it is working, open the transmission device, the transmission device drives multiple sets of clamping devices to move, the clamping device at the top of the transmission device transmits to the right, and passes through the external mechanical arm Put the lamps to be detected one by one into the clamping device in the transmission state on the left side of the top of the conveying device, and the clamping device drives the lamps to convey to the right. The first inductor 5 detects the magnetic block 6 on it, and the centralized control box 3 controls the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com