A kind of low anisotropy non-oriented silicon steel for hydroelectric power generation and its production method

An anisotropic, oriented silicon steel technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., to achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A production method of low anisotropy non-oriented silicon steel for hydroelectric power generation with a thickness of 0.50mm, comprising the following steps:

[0031] The molten steel is smelted according to the production process of molten iron pretreatment, converter smelting, and RH refining. After RH refining, the chemical composition mass percentages of the molten steel at the end point are Si: 3.2%, Mn: 0.30%, Als: 1.0%, B=0.0025%, Cu =0.02%, [S+C+N+Ti]=72ppm, and the rest is Fe and inevitable impurities.

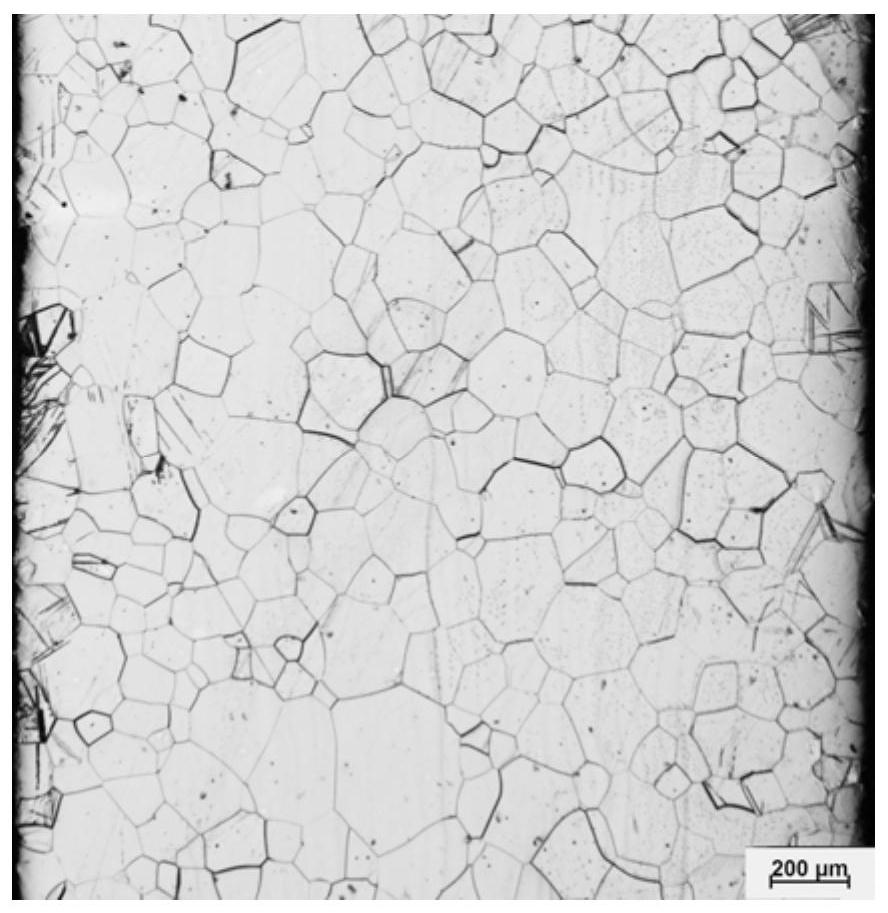

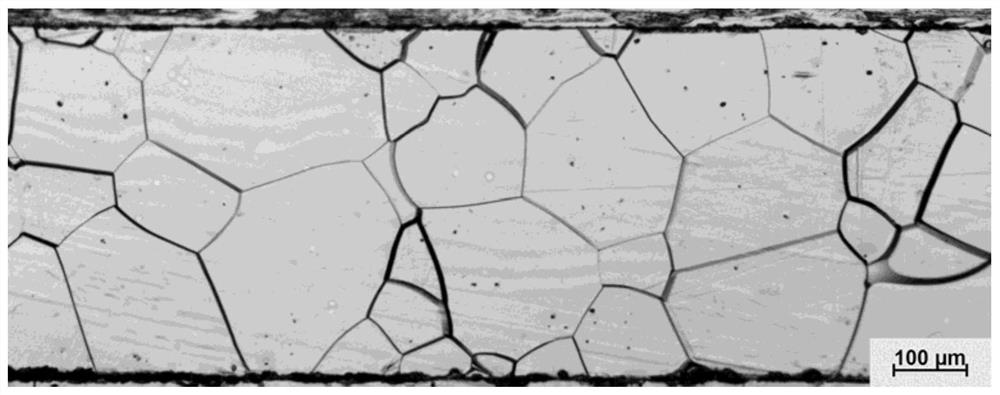

[0032] Continuous casting adopts electromagnetic stirring to obtain 230mm×10m billet, of which the equiaxed crystal ratio of the section structure of the billet is 70%;

[0033] The billet was heated at 1110°C, the soaking time was 70min, the finishing rolling was 2.0mm in 7 passes, and the final rolling temperature was set at 900°C;

[0034] The steel strip is carried out at a normalization temperature of 900°C, and then the normalized steel strip is rolled...

Embodiment 2

[0040] Others are the same as in Example 1, except that:

[0041] The finish rolling temperature was set to 840°C, and the normalization temperature was set to 840°C.

[0042] The non-oriented silicon steel products prepared by the above-mentioned components and processes are tested in accordance with the methods in GB / T 2521.1-2016 and GB / T13789. The obtained magnetic properties, iron loss P 1.5 / 50 =2.35W / Kg, magnetic induction B 50 =1.67T, non-oriented silicon steel products with iron loss anisotropy of 8.7%, meeting the design requirements of hydropower equipment.

Embodiment 3

[0044] Others are the same as in Example 1, except that:

[0045] (1) The mass percentage of chemical composition is Si: 3.0%, Mn: 0.11%, Als: 0.75%, B: 0.0013%, Cu=0.015%, [S+C+N+Ti]=64ppm, the rest are Fe and cannot be impurities to be avoided;

[0046] (2) The proportion of equiaxed crystals in the slab is 63%;

[0047](3) The heating rate of the annealing furnace is 13℃ / s, the holding time of the temperature section of the annealing process is 80s, and the tension in the furnace is 0.9N / mm 2 .

[0048] The non-oriented silicon steel products prepared by the above-mentioned components and processes are tested in accordance with the methods in GB / T 2521.1-2016 and GB / T13789. The obtained magnetic properties, iron loss P 1.5 / 50 =2.31W / Kg, magnetic induction B 50 =1.66T, non-oriented silicon steel products with iron loss anisotropy of 8.1%, meeting the design requirements of hydropower equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap