Mounting part of assembly type sound insulation wall

A technology for installing components and assembling, which is applied in the direction of building components, walls, building structures, etc. It can solve the problems of inconvenient installation and disassembly, and achieve the effects of simple installation process, increased work efficiency, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

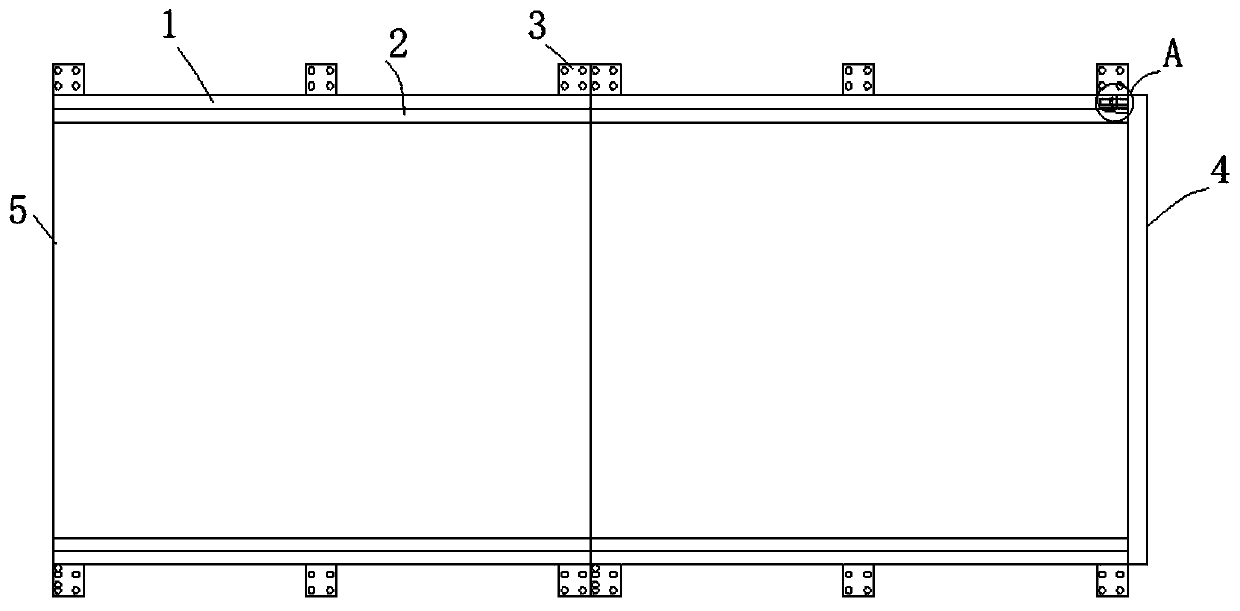

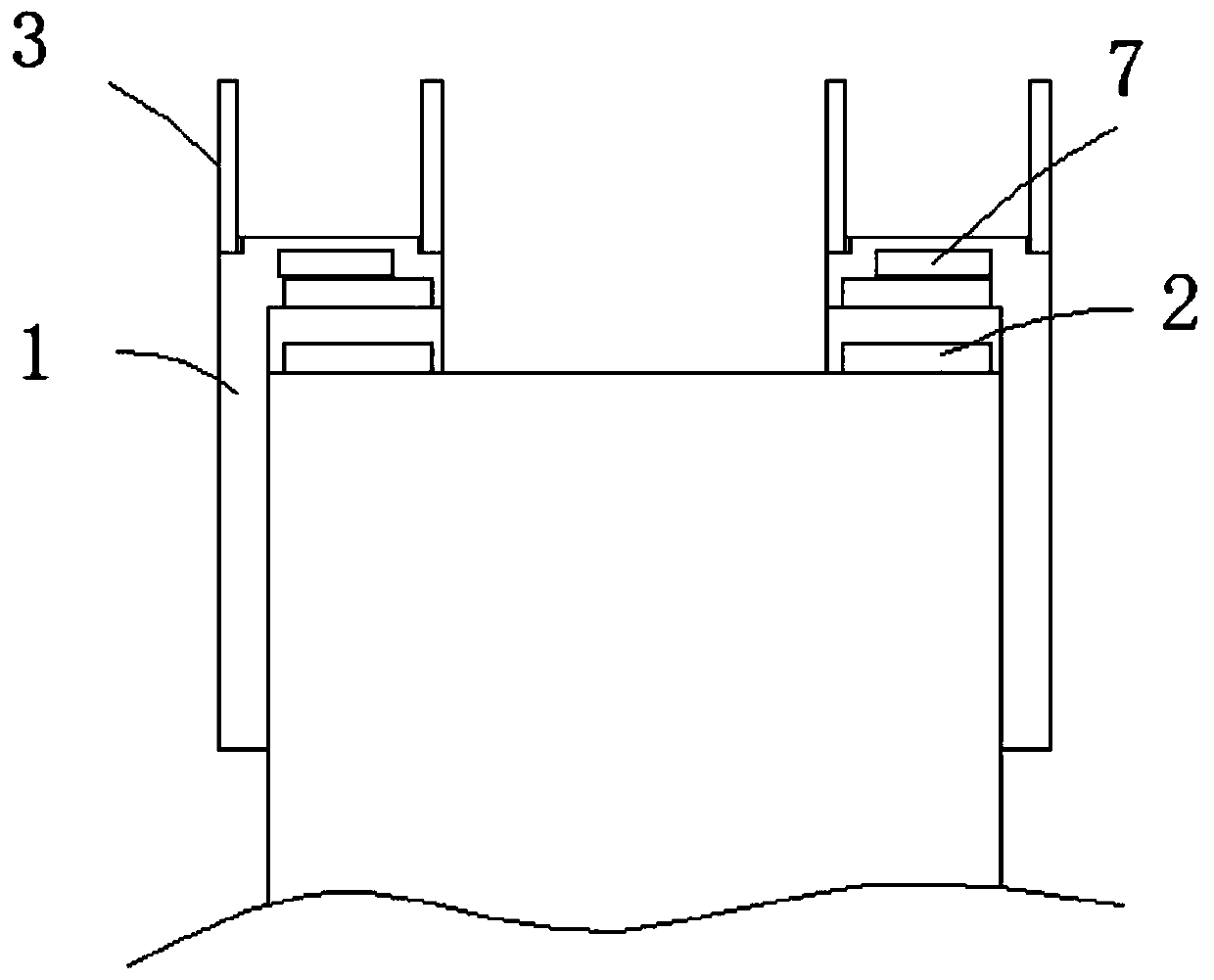

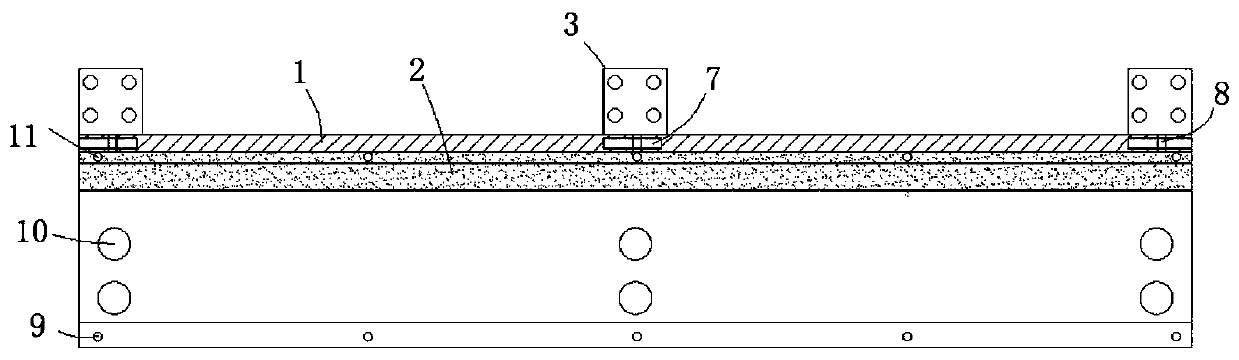

[0029] Embodiment 1: Insert the connecting piece 3 into the concrete wall at the top and bottom, and then drive the fixed pins or bolts to fix the fixing plate 1 to the designated fixture. Pass through the side of the fixed plate 1, follow the fixed groove in the fixed plate 1, enter between the two fixed plates 1, connect, slide to the designated position, and then use the second pin 8 to connect the fixed plate 1 with the sound insulation wall The main body 5 is fixed, and when it is installed to the last side, install the package plate 4 on one side of the front end and the last end of the fixed plate 1, and fix it with the third pin 8 to complete the installation. When replacing the wall or disassembling, The encapsulation board 4 and the main body 5 of the sound insulation wall are disassembled in turn, and the fixing board 1 is directly disassembled as required, and the fixing board 1 after disassembly can still be reused next time.

Embodiment 2

[0030] Embodiment 2: Insert the connecting piece 3 into the concrete wall at the top and bottom, and then drive the fixed pins or bolts, and fix the fixing plate 1 to the designated fixture. The upper side or the lower side of the upper or lower side is slidingly connected to the upper connecting bar 2, and the second pin 9 is used to fix the sound insulation wall main body 5 and the connecting bar 2, and then the connecting bar 2 is aligned with the side of the fixing plate, and along the fixing plate The fixing groove in 1 enters between the two fixing plates 1 for connection, and after sliding to the designated position, the second pin 8 is used to fix the fixing plate 1 and the connecting strip 2 to adapt to some errors between the walls , to facilitate installation. When installing to the last side, install the package plate 4 on the front and rear end of the fixed plate 1, fix it with the third pin 8, and complete the installation. After replacing the wall or carrying out...

Embodiment 3

[0031] Embodiment 3: Fold the connecting sheet 3, and then connect bolts in the connecting holes on the connecting sheet 3, and then fix it in the concrete wall at the top and bottom. It is also possible to use the cooperation between the limited hole 10 and the bolt to fix the The board 1 is fixed on the designated fixture, at this time, according to the needs, the upper side or the lower side of the sound insulation wall main body 5 is slid to connect the upper connection strip 2, and the second pin 9 is used to fix the sound insulation wall main body 5 and the connection strip 2 Connect, and then align the connecting strip 2 with the side of the fixed plate, follow the fixed groove in the fixed plate 1, enter between the two fixed plates 1, connect, slide to the designated position, and then use the second pin 8 Fix the fixing plate 1 and the connecting strip 2 to adapt to some errors between the walls and facilitate installation. When installing to the last side, install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com