Down lamp

A downlight and lamp body technology, applied in lighting devices, cooling/heating devices of lighting devices, fixed lighting devices, etc., can solve problems such as economic waste, complex structure of downlights, troubles, etc., to reduce economic costs and simplify the overall The effect of structure, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

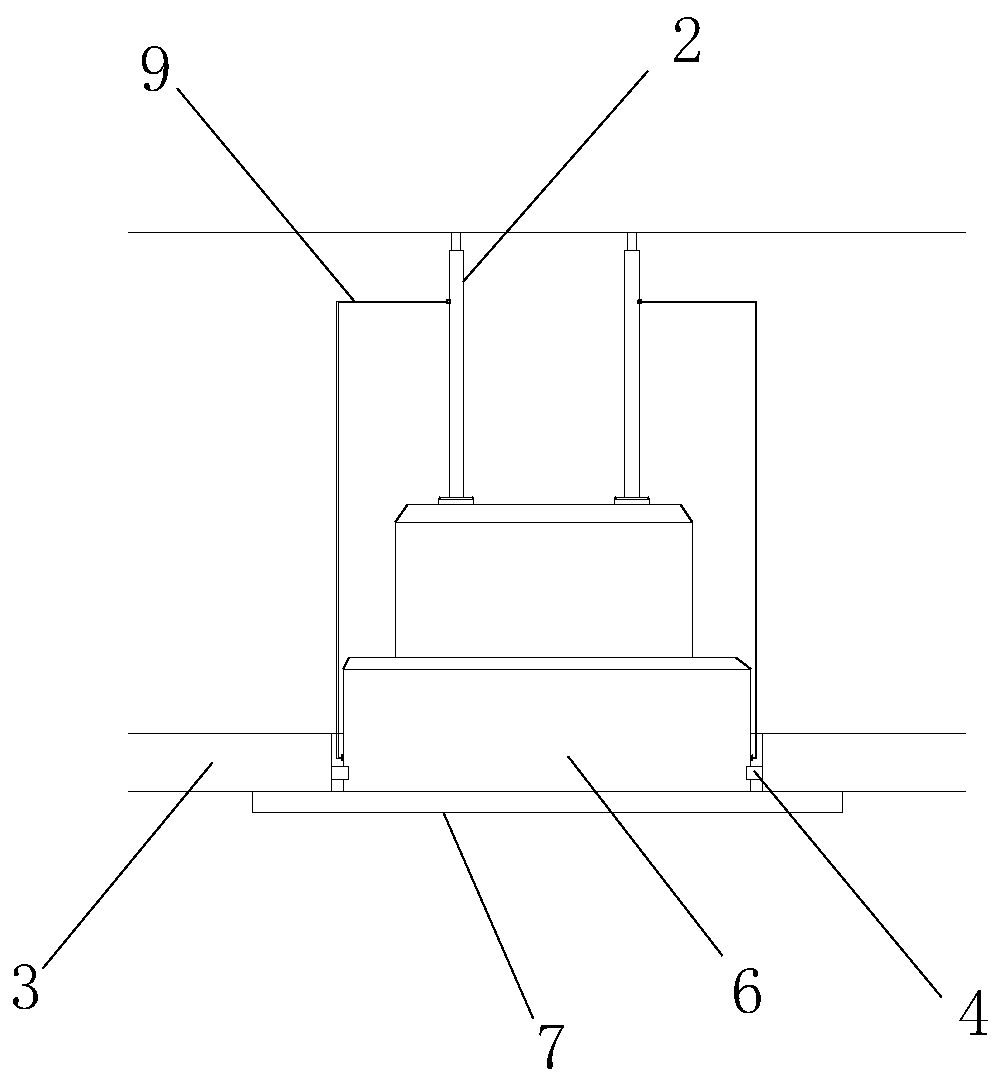

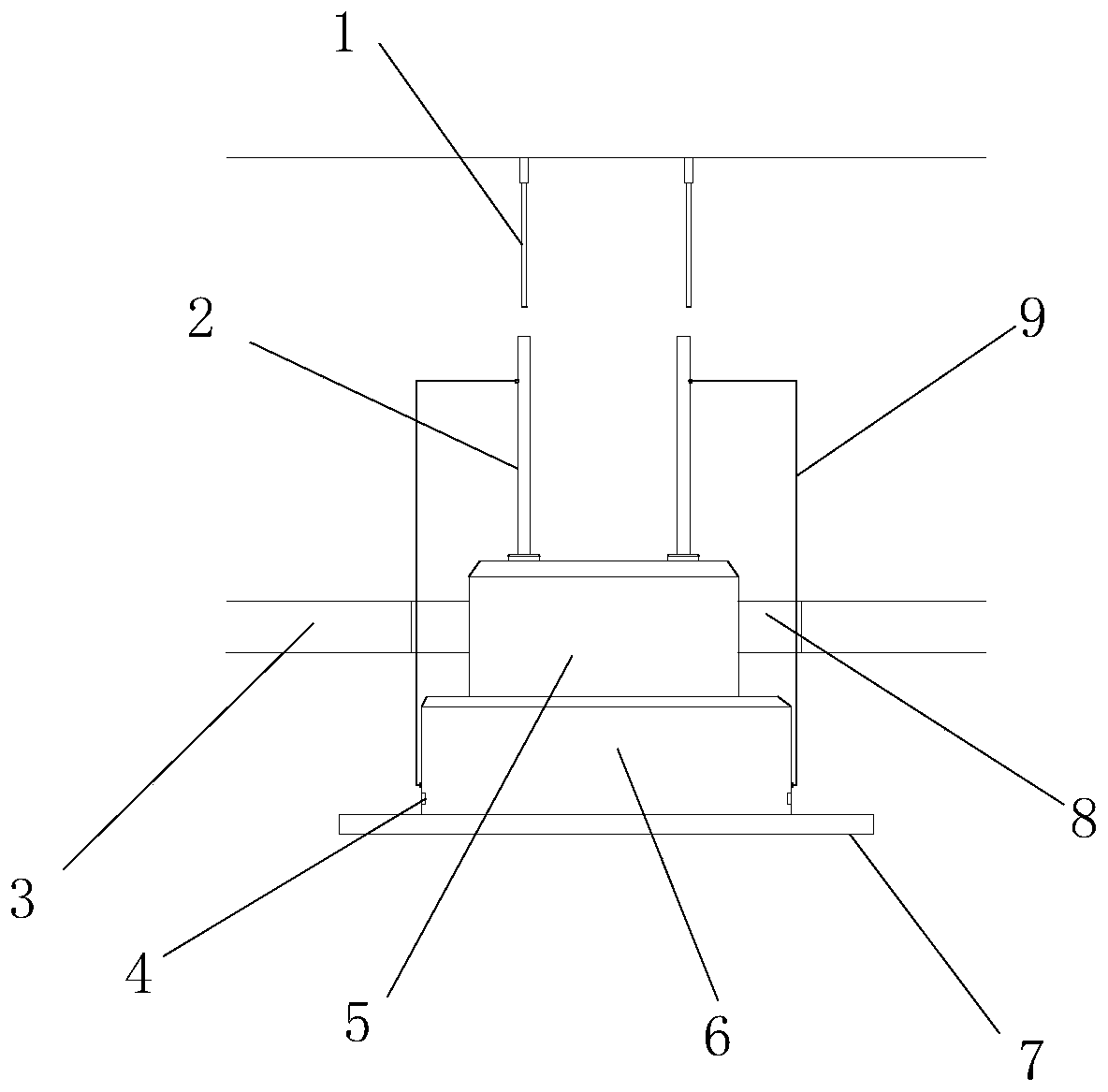

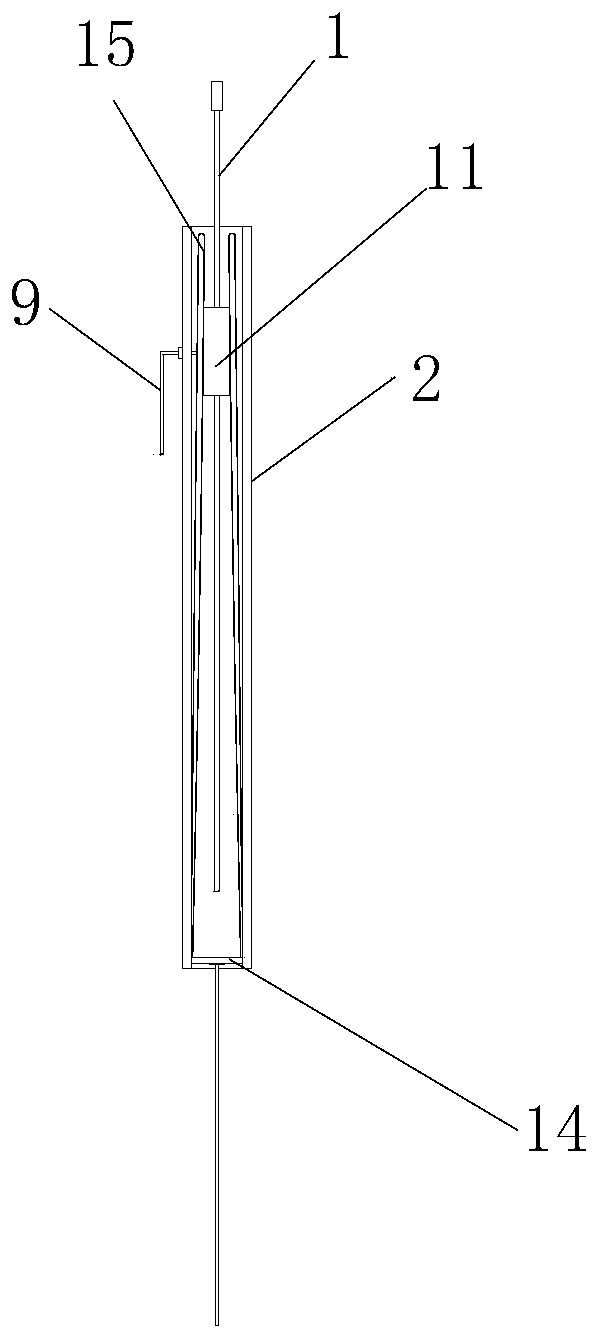

[0018] Such as figure 1 and figure 2 As shown, a downlight includes a lighting lamp body 6, a driving power supply box 5 and a panel 7, the panel 7 is installed on the outer end of the lighting lamp body 6, the driving power supply box 5 is installed on the inner side end of the lighting lamp body 6, and the driving power supply Installed in the driving power supply box 5, the entire lighting lamp body 6 passes through the preset hole 8 opened on the gypsum top plate 3, and two heat-conducting copper pillars 2 are arranged on the outer end surface of the driving power supply box 5, and there is a heat-conducting copper pillar 2 inside. Wiring cavity 12, the bottom of the wiring cavity 12 communicates with the inside of the drive power supply box 5, and the bottom of the wiring cavity 12 is fixedly provided with a terminal base 14 close to one end of the drive power supply box. Sheet 15, a docking cavity is formed between the wiring copper sheets 15, the top opening of the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com