Relay armature deformer

A deformer and relay technology, applied in relays, circuits, electrical components, etc., can solve problems such as poor deformation effect, inability to locate, and generation of foreign objects, so as to avoid repeated deformation, improve production efficiency, and produce no foreign objects and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

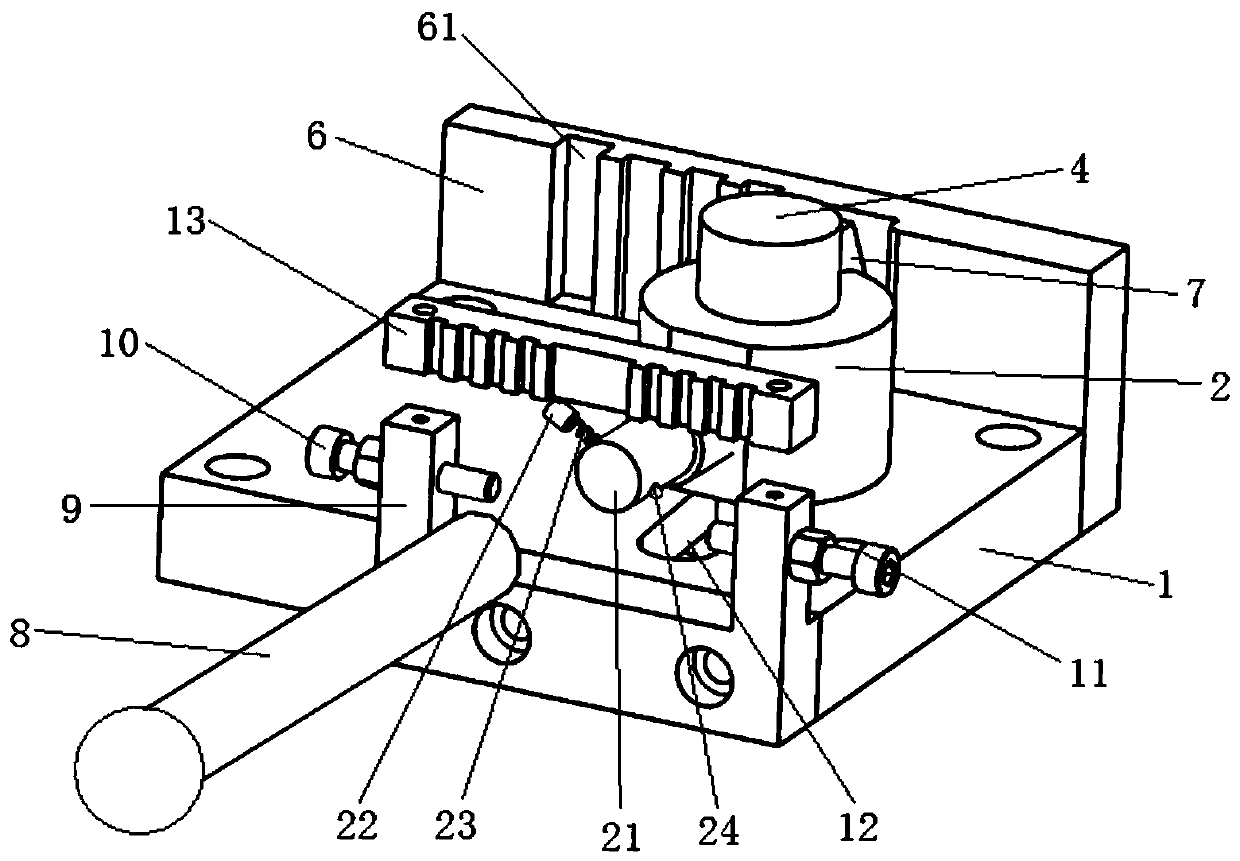

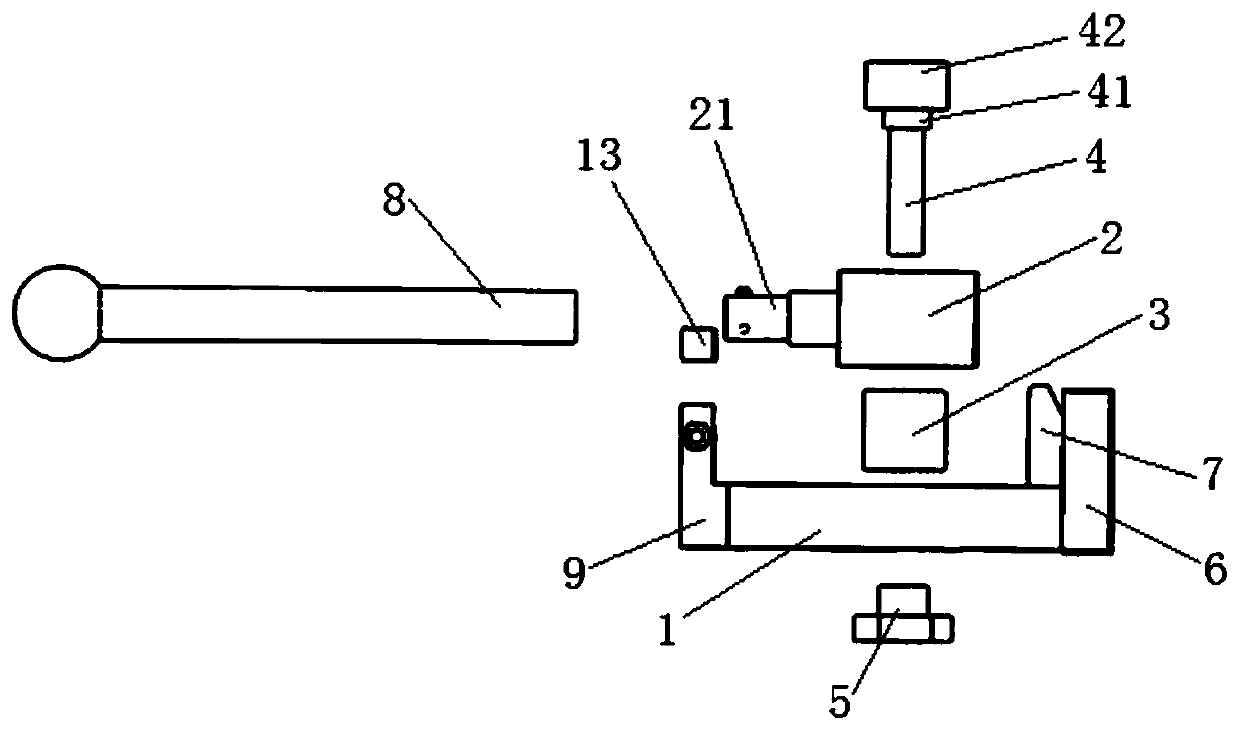

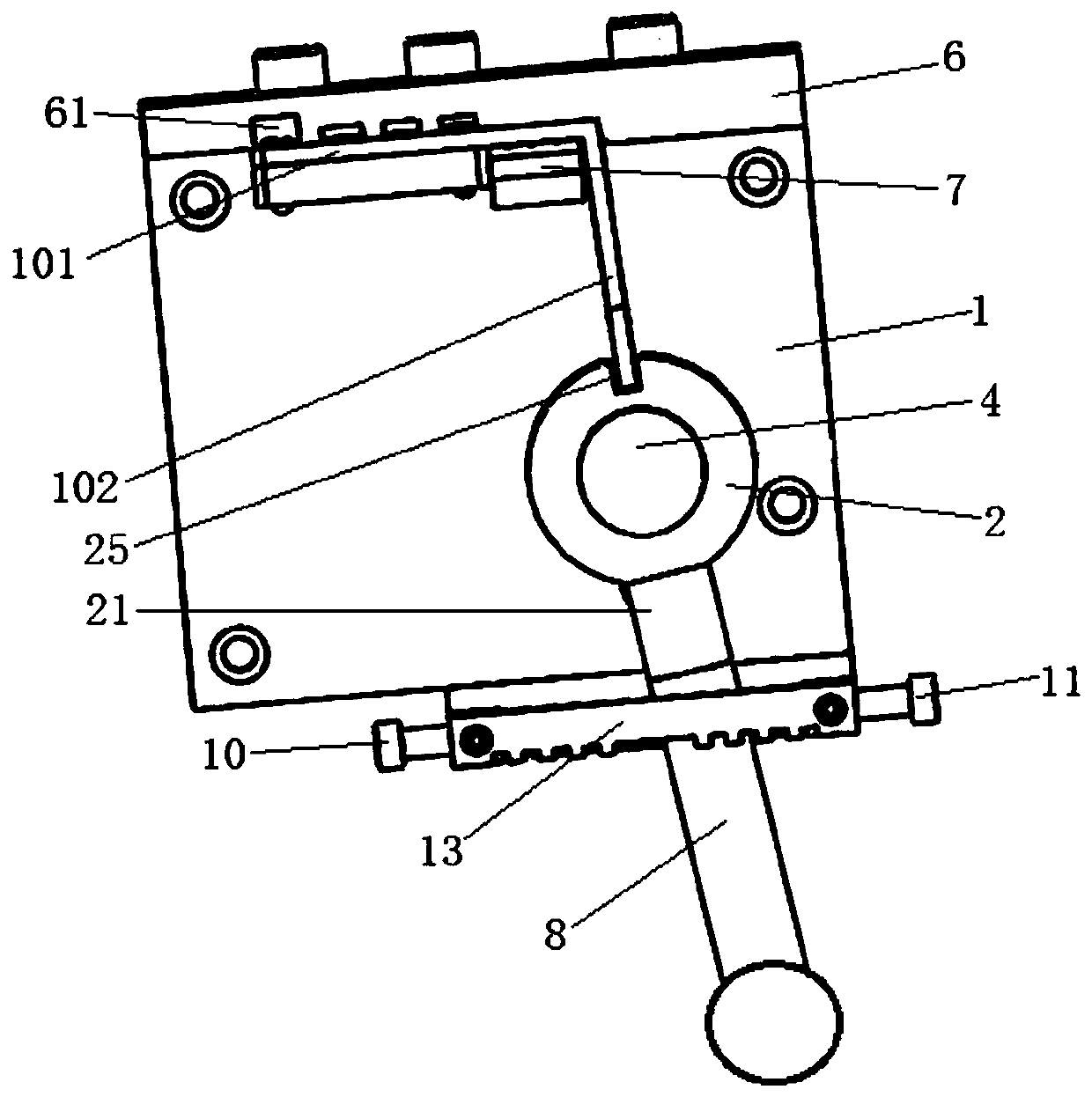

[0014] like Figures 1 to 3 As shown, a relay armature deformer of the present invention includes: a base 1, a rotary deformer 2, a positioning bushing 3, a positioning nail 4, a guide locking nail 5, a first limit plate 6, and a second limit plate 7. Rod 8, angle limiter 9, left limit pin 10 and right limit pin 11.

[0015] The positioning shaft sleeve 3 is a cylindrical structure, the rotary deformer 2 is sleeved on the outside of the positioning shaft sleeve 3, the base 1 is provided with a sliding slot 12, the positioning nail 4 and the guide locking nail 5 Respectively extend from the upper and lower sides of the sliding slot 12 into the positioning bushing 3 to lock the positioning bushing 3 on the base 1 by screwing. The screw heads are embedded in the steps to ensure the flatness of the bottom surface of the base 1. The first limit plate 6 is fixed on one side of the base 1 , the second limit plate 7 is riveted to the base 1 , a mounting groove is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com