Patents

Literature

37results about How to "No foreign matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

Production of pure soya-bean lactacidase fermenting beverage

InactiveCN1644112AFine tissuePure bean flavorFood preparationMilk substitutesStreptococcus thermophilusBiology

A fermented lactobacillus beverage is prepared from soybean through preparing soybean milk, inoculating thermophilic streptococcus and lactobacillus, fermenting, dispensing, homogenizing and sterilizing. Its advantages are agreeable taste, not containing cholesterine and lactose, and high nutritive value.

Owner:JIANGNAN UNIV

Health care teabag and production method thereof

InactiveCN102450353ABright soupFresh sweet potato flavor is obviousPre-extraction tea treatmentCooking & bakingAdditive ingredient

The invention belongs to the field of food processing and specifically relates to a health care teabag. The invention provides the health care teabag which tastes good and has a health care function. A production method for the teabag comprises the following steps: cleaning stems and leaves of sweet potato, green tea and haw three times, spreading and airing the above motioned raw materials for one hour so as to dispersing unwanted green taste, deactivating enzyme with steam so as to kill enzyme and remove a fishy smell, then transferring the raw materials into a baking oven for baking by using variable temperature heating, standing the raw materials in the baking oven after baking so as to allow temperature of the raw materials to drop back and moisture to be uniformly distributed anew, crushing an obtained sample, screening the crushed sample with a 20-mesh sieve, uniformly mixing the sample with other ingredients, seal packaging an obtained product, storing the product at normal temperature, reheating green tea and haw at a temperature of 70 DEG C so as to remove unwanted moisture, allowing the temperature of green tea and haw to drop back so as to balance moisture, crushing green tea and haw, carrying out screening with a 20-mesh sieve and standing obtained green tea and haw for subsequent usage. A formula used in the invention is as follows: addition amount of haw is 10 to 15%, addition amount of green tea is 10 to 15%, and addition amount of leaves of sweet potato is 75 to 85%.

Owner:袁景瑞

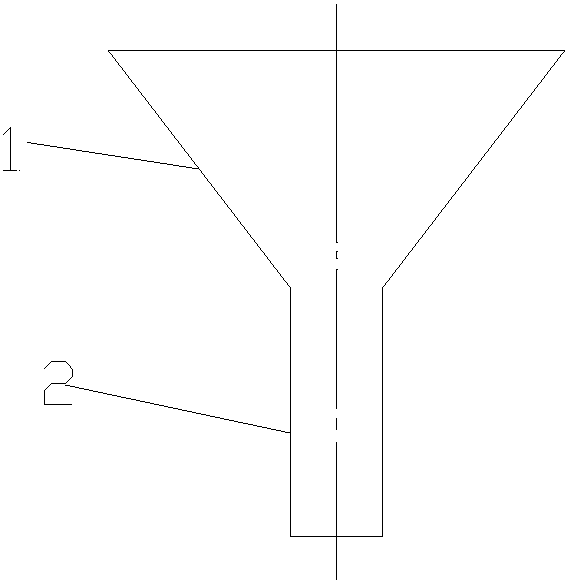

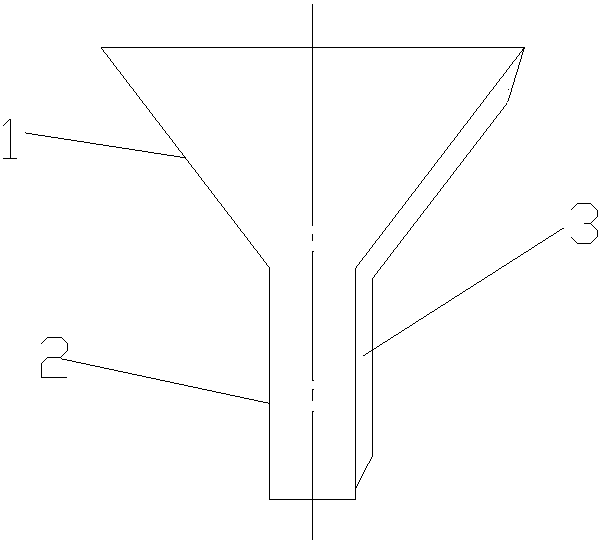

Environment-friendly anticorrosive coating and preparation method thereof

The invention belongs to the field of preparation of coatings and particularly relates to an environment-friendly anticorrosive coating and a preparation method thereof. The coating is prepared by mixing an oil paint component and a curing agent component in a weight ratio of 100 to (20-30). The oil paint component is prepared from the following components in percentage by weight: 55-70wt% of acrylic resin, 5-15wt% of tea stem powder, 10-15wt% of organic pigments, 3-5wt% of rosin, 10-15wt% of solvent and 2-5wt% of surfactant. The curing agent component is prepared from the following components in percentage by weight: 60-69wt% of curing agent, 30-39wt% of solvent and 0.05-1wt% of dehydrating agent, wherein the dehydrating agent is one or two of butyl ester, cyclohexanone and butyl cellosolve. The added tea stem powder can react with harmful gases such as formaldehyde and dimethylbenzene to form non-volatile harmless macromolecular chain substances, so as to effectively eliminate harmful gases in the atmosphere, so that the prepared coating is relatively environmentally friendly and pollution-free. Due to the design of a stepwise feeding device, the raw materials are fully and uniformly mixed, thereby improving the performance of the coating. Due to adoption of a discharging spill-proof hopper, the packaging process is simple, convenient and efficient.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

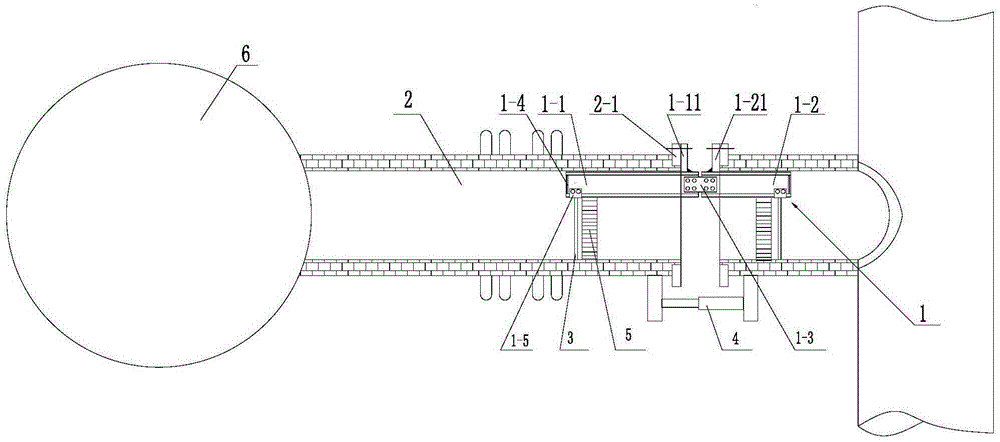

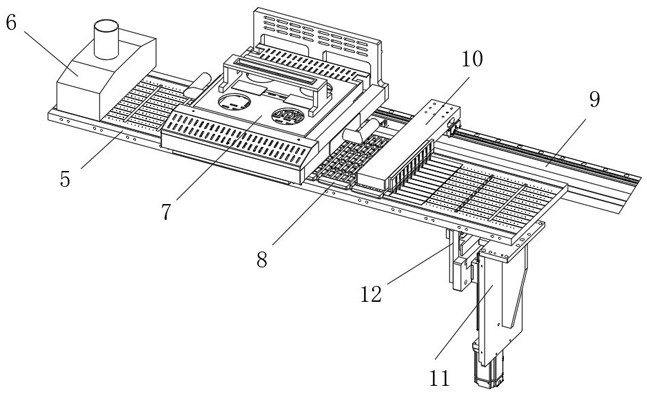

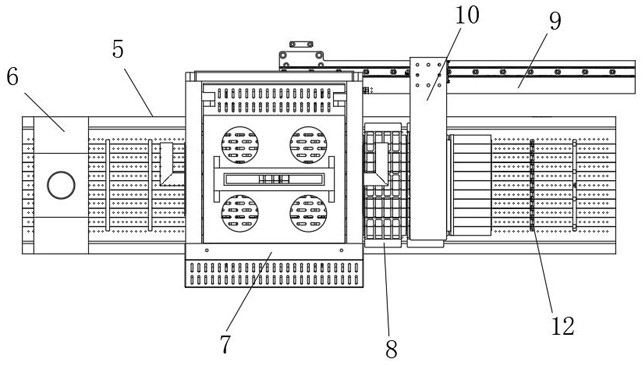

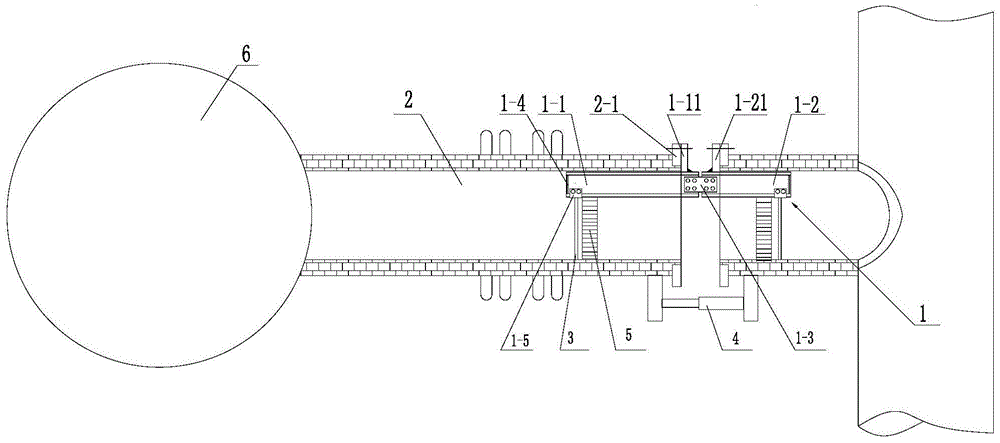

Repair tooling of hot-blast branch pipe lining of hot-blast furnace and repair method thereof

ActiveCN105369002ANot affected by low temperatureEnsure safetyBlast furnace detailsHeating stovesBlowing downRepair method

The invention relates to a repair tooling of a hot-blast branch pipe lining of a hot-blast furnace and a repair method thereof. The repair tooling comprises split type structural support track beams including a left support track beam and a right support track beam, wherein the support track beams are connected with end flanges of hot-blast branch pipes, two sliding trolleys are installed on the support track beams in a sliding mode, and insulation blind plates are respectively hoisted on each sliding trolley. The hot-blast branch pipe lining of the hot-blast furnace is repaired in a hot state of the hot-blast furnace by utilizing the repair tooling of the hot-blast branch pipe lining of the hot-blast furnace, and the repair method mainly comprises the following steps that after the blast furnace blows down, firstly, the hot-blast furnace is put in a cold stoking state, the condition that the states of all valves meet operation requirements on site is confirmed, the lining repair tooling is installed, an insulation wall is built, the lining is repaired, the repair tooling and the insulation wall are disassembled, and the hot-blast furnace is reassembled and started to normally supply air. According to the scheme, the lining of the hot-blast furnace cannot be influenced by low temperature, and the repair can be quickly realized; in an actual repair process, the safety of operating personnel is guaranteed, and the repair difficulty is reduced; additionally, a hot-blast valve is installed with time saving and labor saving, and the operating efficiency is greatly improved.

Owner:TIANJIN IRON & STEEL GRP

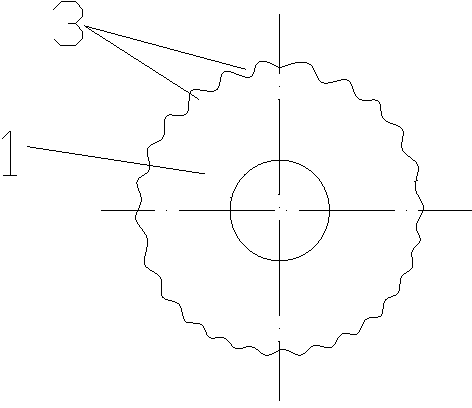

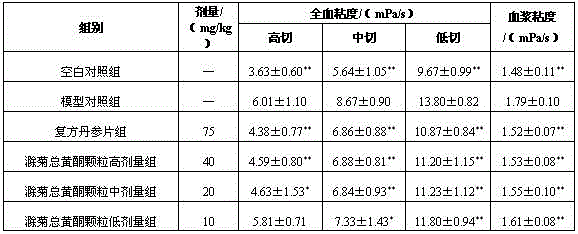

Chuzhou chrysanthemum general flavone grains as well as preparation method and application thereof

ActiveCN102973628ANo foreign matterGood molding effectGranular deliveryBlood disorderBiotechnologySucrose

The invention discloses Chuzhou chrysanthemum general flavone grains, which are formed by the following raw materials in weight ratio of sucrose powder to dextrin to dry Chuzhou chrysanthemum general flavone extract powder of (0.5-1.5): (1.5-2.5): (0.5-1.5). The Chuzhou chrysanthemum general flavone is prepared into a granular formulation and the granular formulation has the good molding performance; the performance, the granularity, the water, the dissolubility and the like meet the requirements; the quality is controllable and the stability is good; commodity chrysanthemums are prevented from color change and smell loss in a storing process; the content of effective components is not reduced; and a phenomenon that the color of separated parts in an immersing process becomes green is avoided. The Chuzhou chrysanthemum general flavone grains can obviously delay blood caking time of rats with blood stasis due to cold accumulation, reduce the length, and dry and wet weights of in-vitro thrombus, reduce deposition of red blood cells, decrease red blood cell settling speed and raise the NO content of blood serum. The product has the characteristics of convenience for carrying and drinking, easiness for storing, no toxic or side effect, capabilities of preventing, treating and improving abnormal conditions of hemorheology of the rats with the blood stasis, and the like.

Owner:ANHUI JUTAI CHUJU HERBAGE TECH +1

Method for preparing chicken feet with pickled peppers

The invention relates to a method for preparing chicken feet with pickled peppers. The method comprises the following specific operation steps: (1) pretreating raw materials, namely, washing white, stain-free and odor-free chicken feet; (2) segmenting, namely, segmenting the chicken feet into 3-4 blocks; (3) soaking and whitening, namely, soaking the segmented chicken feet for three times by using a composite salt soaking solution, wherein a weight ratio of the chicken feet to the composite salt soaking solution is 1:(4-5); (4) boiling, namely, boiling for 9-10 minutes; (5) cooling to room temperature, infusing by using pickled pepper infusing solution, sterilizing, performing vacuum package and checking, wherein the composite salt soaking solution consists of the following substances in parts by weight: 3-5g of salt, 0.1-0.3g of sodium bicarbonate and 95-97g of water, and the water is living and drinking water which meets the national standard and has a pH value of 6.5-6.8.

Owner:HEFEI UNIV OF TECH

Processing technology of honeysuckle flower tea beverage

The invention discloses a processing technology of honeysuckle flower tea beverage. The processing technology of the honeysuckle flower tea beverage comprises the following steps: extracting the honeysuckle flowers, compounding the honeysuckle flower tea beverage, carrying out checking, and carrying out canning and so on. The prepared honeysuckle flower tea beverage is capable of improving body immunity, promoting cell growth, delaying cell senescence, improving sleep, resisting tumors, resisting oxidation, reducing blood lipid, reducing blood sugar, clearing away heat and detoxifying. The honeysuckle flower tea beverage is especially a good blood-nourishing and youth-keeping product for the female friends, and is capable of improving anemia as well as making the skin red, moistened, fined and smooth. The honeysuckle flower tea beverage has wide market prospects.

Owner:聂超

Active lactic acid bacteria beverage and manufacture method thereof

The invention belongs to a diary product field and in particular relates to an active lactic acid bacteria drink and a production method thereof. In the active lactic acid bacteria drink of the invention, water is a base material and components with the following quality content are included: 0.5%-2.0% of beneficial bacteria, 0.8%-1.2% of protein, 1%-5% of glucose, 9%-12% of sucrose and 0.4-0.5% of emulsification stabilizer. The active lactic acid bacteria drink of the invention increases quantity of live bacteria of the lactic acid bacteria and the drink contains both animal protein and plant protein. Besides, through filtering and reasonably collocating strain of the lactic acid bacteria, over 0.1 billion live bacteria exist in the products per milliliter so that a large amount of bacteria can live in intestinal tract and reach a large quantity so as to bring the function of regulating flora and improving immunity.

Owner:广州合诚实业有限公司

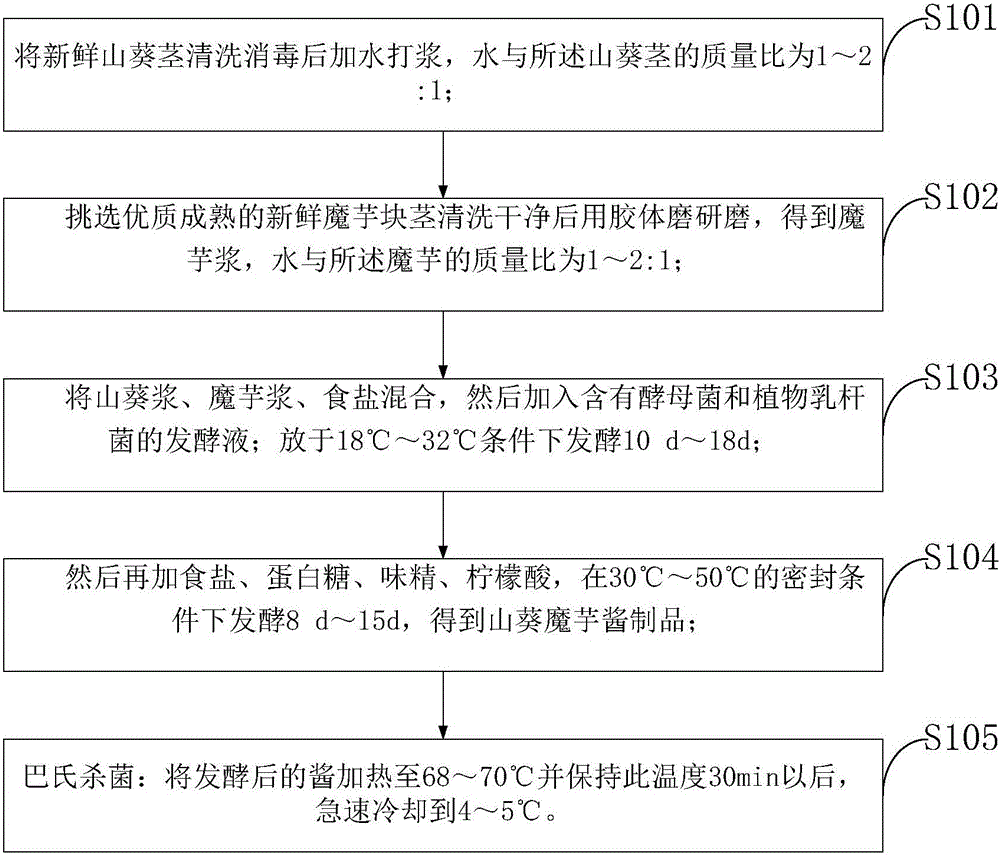

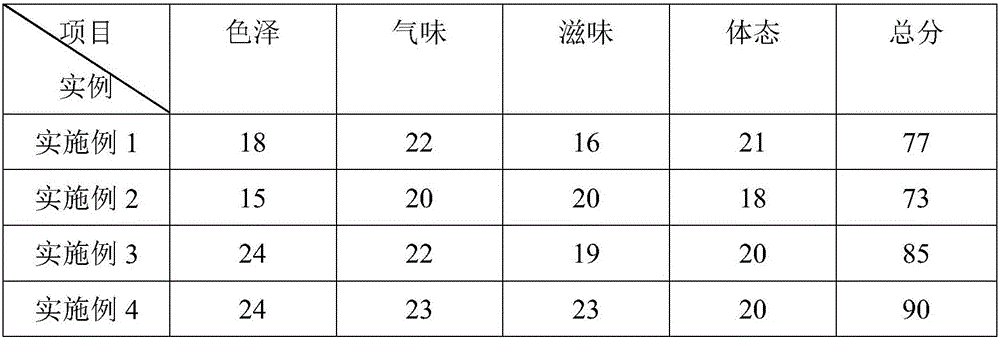

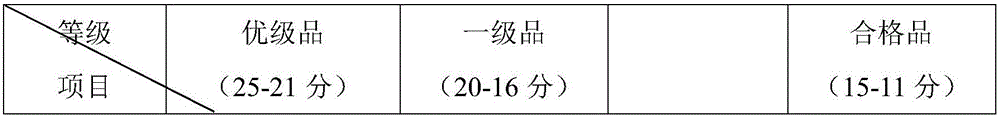

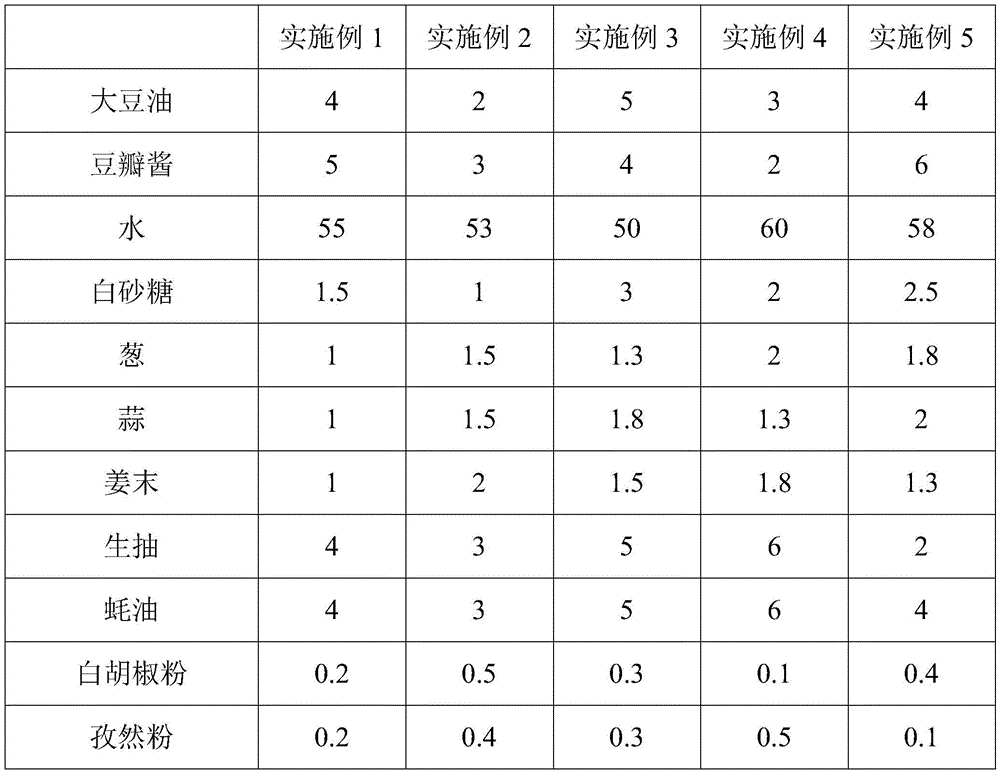

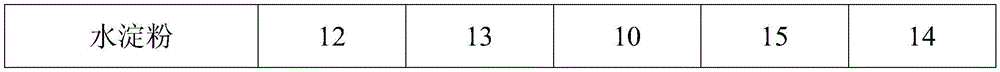

Wasabi-konjac sauce and preparation method thereof

InactiveCN105795444AUnique flavorFull of nutritionSugar food ingredientsYeast food ingredientsMonosodium glutamateYeast

The invention discloses a wasabi-konjac sauce and a preparation method thereof. The wasabi-konjac sauce is prepared from the following ingredients in parts by mass: 80-120 parts of wasabi pulp, 300-400 parts of konjac pulp, 30-50 parts of table salt, 3-8 parts of aspartame, 4-7 parts of monosodium glutamate, 0.05-0.08 part of citric acid, 0.05-0.09 part of yeast and 0.06-0.24 part of Lactobacillus plantarum. The preparation method comprises the following steps: washing the fresh wasabi stems, disinfecting the washed wasabi stems, adding water into the disinfected wasabi steams, and pulping the mixture; selecting fresh high-quality mature konjac tubers, fully washing the selected konjac tubers and grinding the washed konjac tubers by a colloid mill, so that a konjac pulp is prepared; uniformly mixing the wasabi pulp, the konjac pulp and the table salt, and adding the yeast and the Lactobacillus plantarum into the mixture; fermenting the mixture at 18-32 DEG C for 10-18 days; and then, adding the table salt, the aspartame, the monosodium glutamate and the citric acid into the mixture, and carrying out sealed fermentation at 30-50 DEG C for 8-15 days, so that a wasabi-konjac sauce product is prepared. The wasabi-konjac sauce product is unique in flavor as well as rich in nutrition, and has healthcare effects.

Owner:XIHUA UNIV

Hair-conditioner composition using natural plant as base material and its preparing method

InactiveCN101069674AScientific and rigorous material selectionRaw materials are easy to getCosmetic preparationsHair cosmeticsLanolinLemon juice

The present invention relates to a composition of hair care product made up by using natural plant as matrix and its preparation method. Said hair care product is made up by using lemon juice, licorice extract, hexadecyl alcohole, lanolin, polyoxyethylene stearate, octadecyl trimethyl ammonium chloride, propylene glycol, purified water, preservative, perfume compound and coloring matter as raw material through the processes of mixing raw materials, filtering, fully stirring and emulsification.

Owner:陈昊 +2

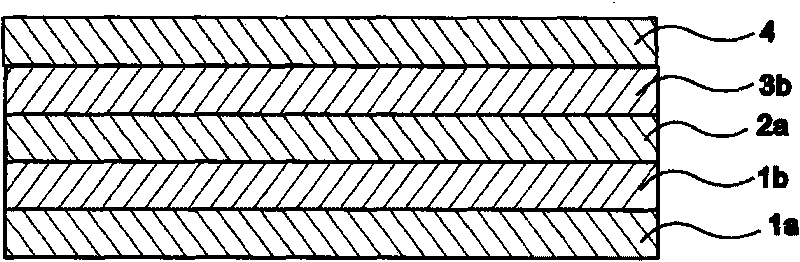

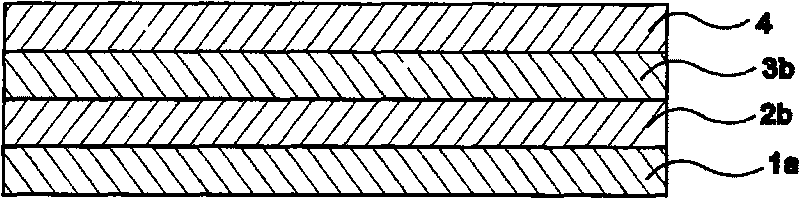

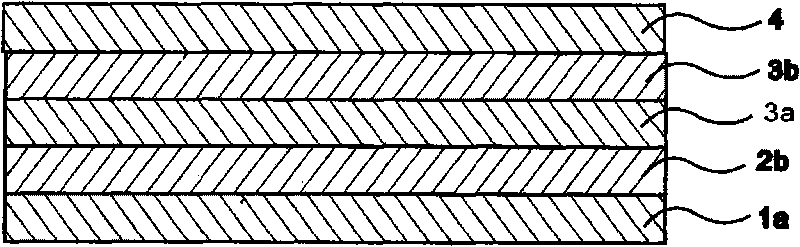

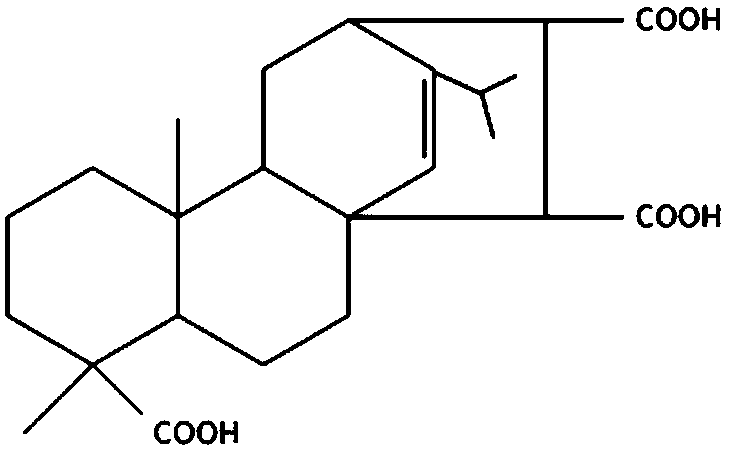

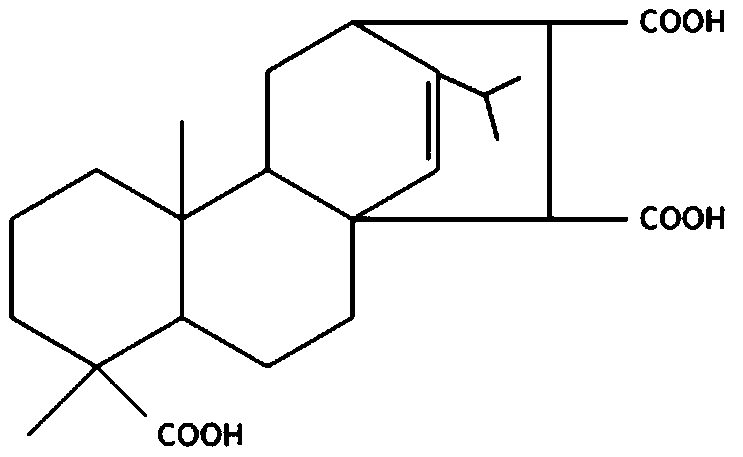

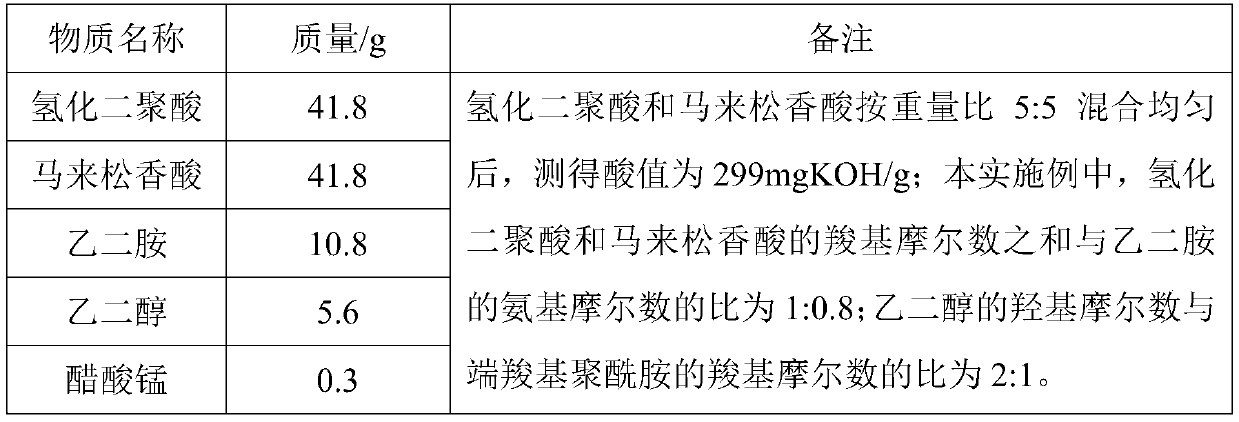

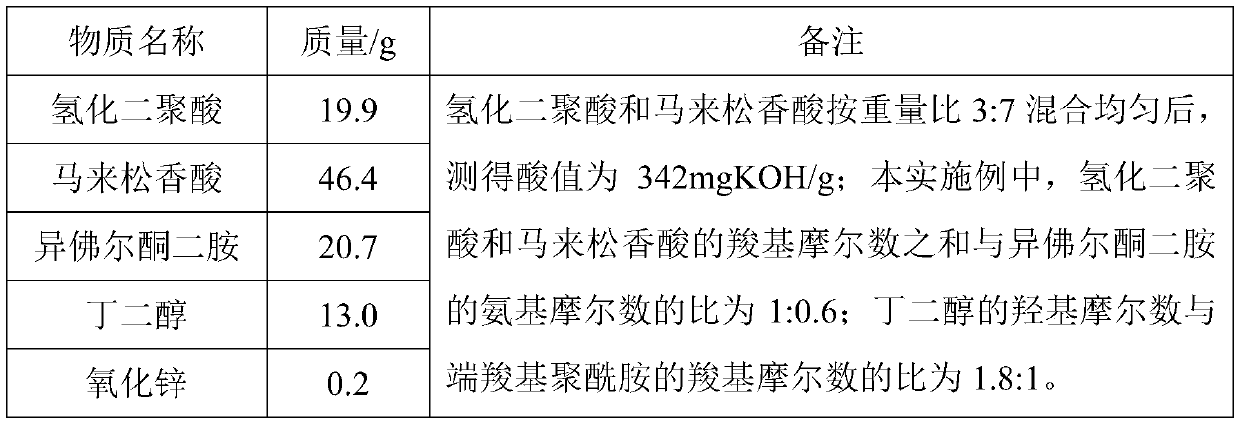

Polyethylene film with high peeling strength on non-aluminized surface of VMPET and preparation method thereof

ActiveCN107903465AGood flexibilityGood adhesionSynthetic resin layered productsForeign matterPolyester

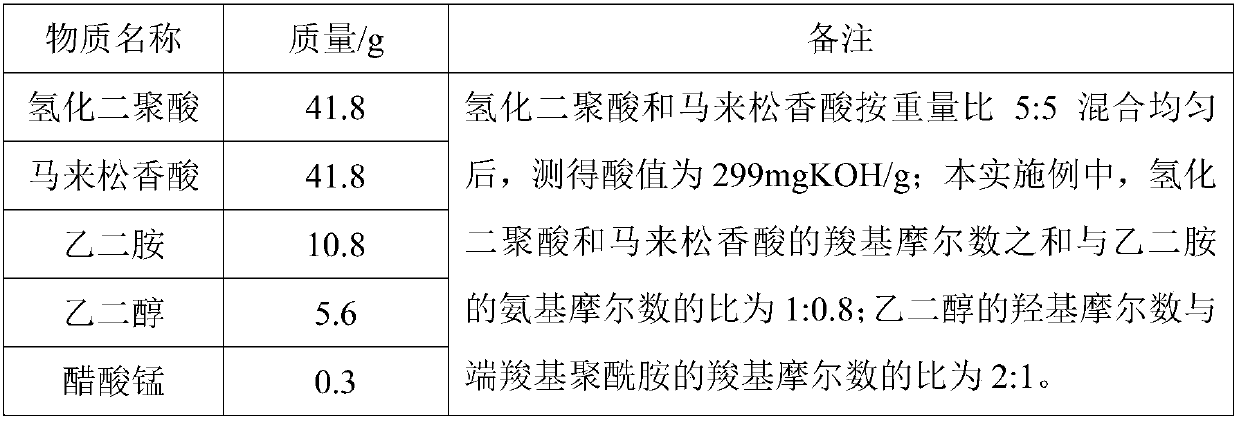

The invention discloses a polyethylene film with high peeling strength on a non-aluminized surface of VMPET and a preparation method thereof. The polyethylene film comprises the following substances by weight: 5 to 15% of hydrogenated dimer acid / rosin-based polyester polyamide, 2 to 5% of maleic anhydride-grafted polyethylene and 80 to 93% of polyethylene, wherein the hydrogenated dimer acid / rosin-based polyester polyamide is prepared by reacting carboxyl-terminated polyamide with dihydric alcohol; the carboxyl-terminated polyamide is prepared by reacting hydrogenated dimer acid with maleic rosin acid and diamine, a weight ratio of the hydrogenated dimer acid to the maleic rosin acid is 5: 5 to 3: 7, and a ratio of the sum of the mole numbers of carboxyl groups in the hydrogenated dimer acid and the maleic rosin acid to the mole number of amino groups in the diamine is 1: 0.6-0.8; and a ratio of the mole number of hydroxyl groups in the dihydric alcohol to the mole number of carboxyl groups in the carboxyl-terminated polyamide is greater than or equal to 1.8: 1. The prepared polyethylene film in the invention has the advantages of smooth surface, uniform color and no foreign matters, and high peeling strength on the non-aluminized surface of a VMPET film.

Owner:FOSHAN SOUTHERN PACKAGING

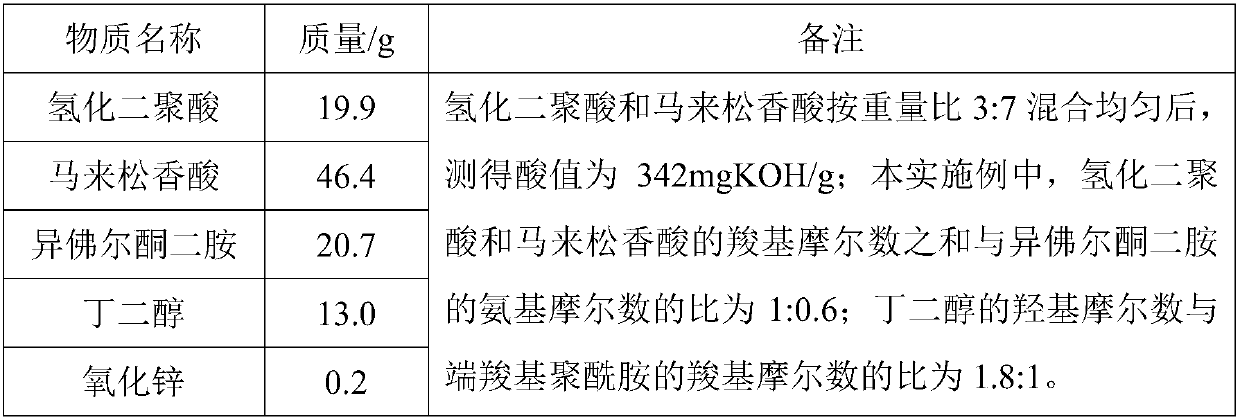

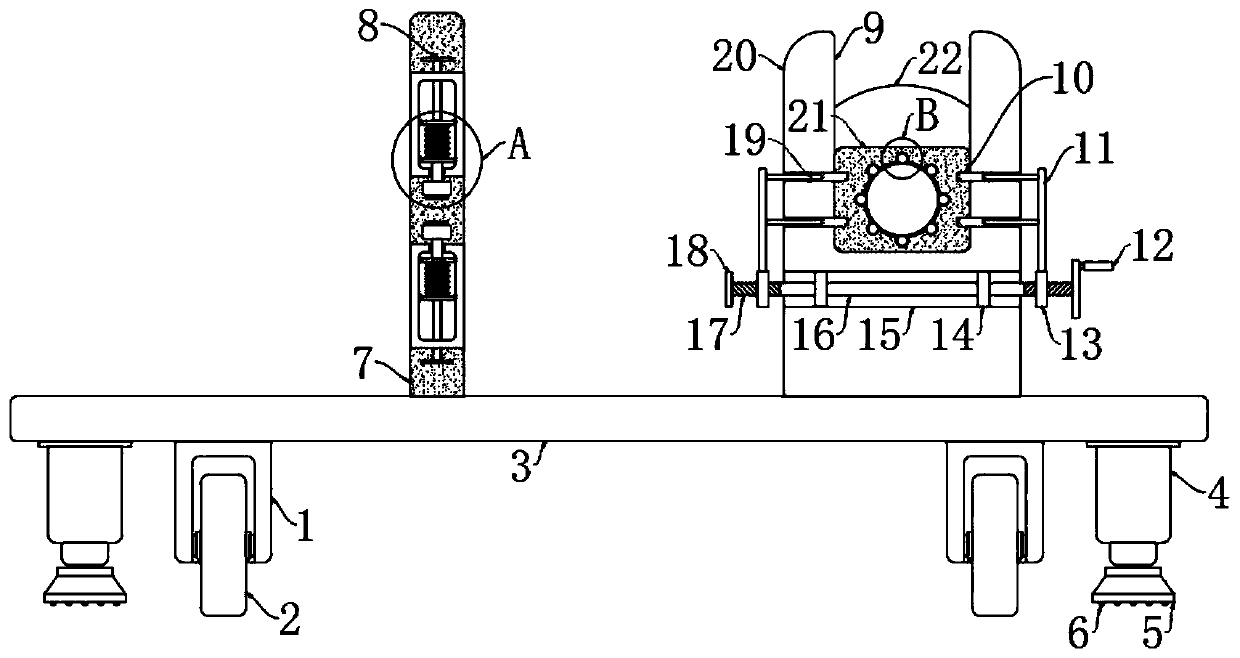

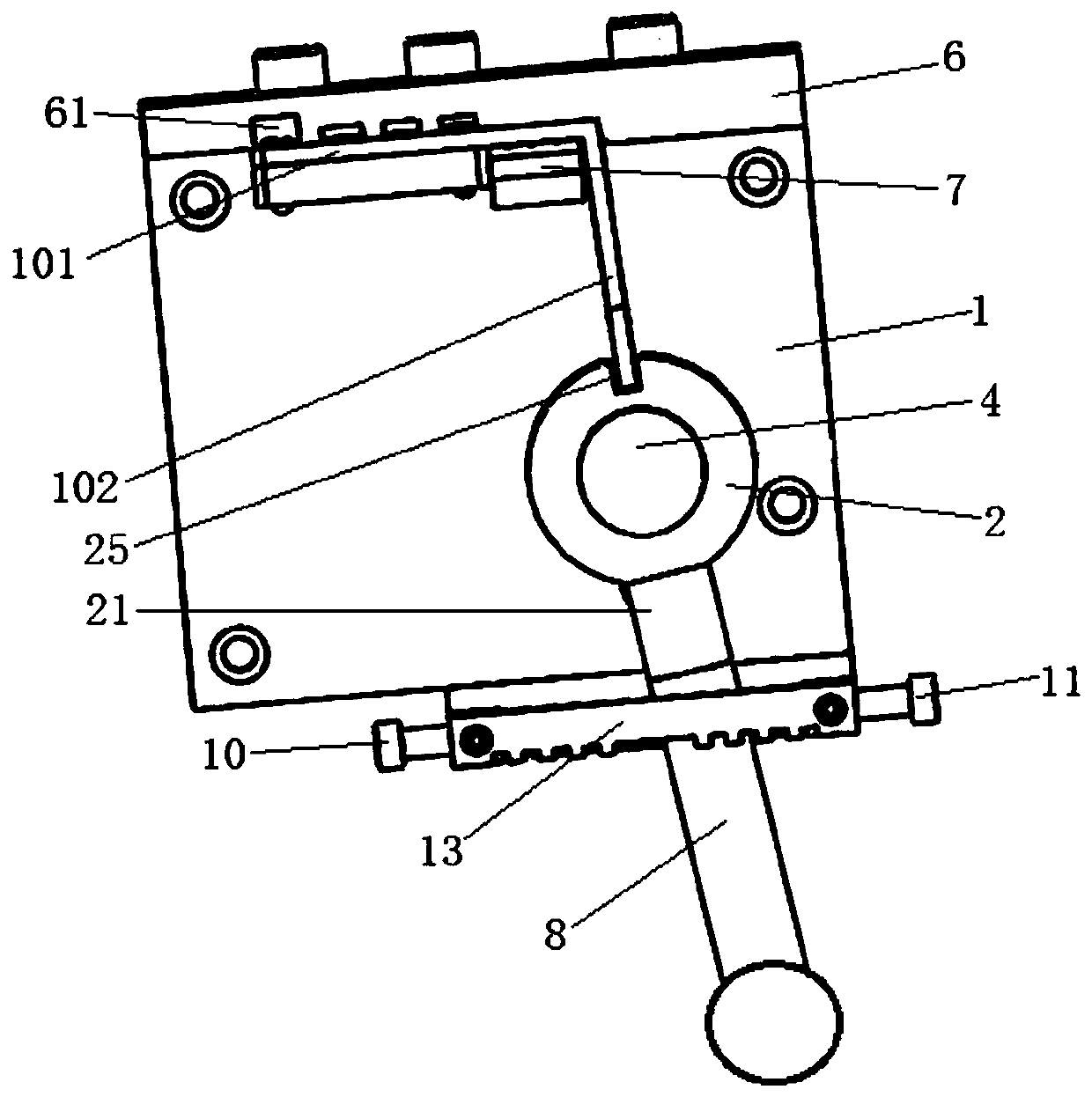

Discharging device for CIPP roll material

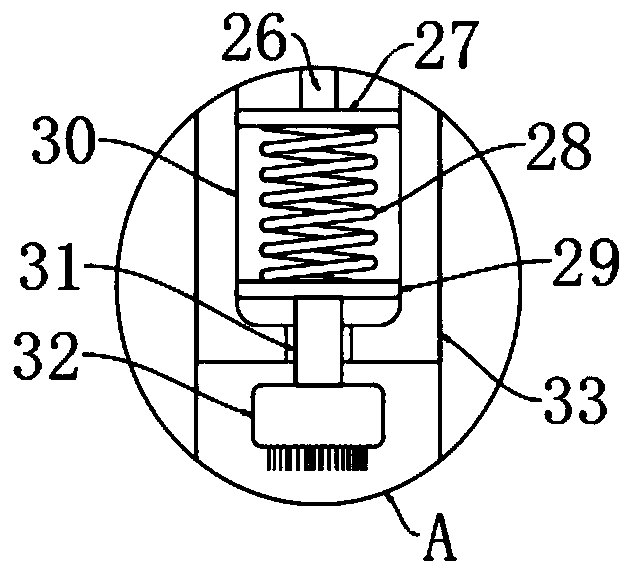

ActiveCN111268497AGuaranteed stabilityPlay the effect of supporting anti-slipFilament handlingCleaning using toolsForeign matterStructural engineering

The invention discloses a discharging device for a CIPP roll material. The discharging device comprises a bottom plate, a plurality of installing frames are arranged on the lower side of the bottom plate, rotatable travelling wheels are arranged inside the installing frames, a plurality of supporting mechanisms are arranged on the lower sides of the installing frames, two symmetrically-arranged fixing plates are fixedly connected to the upper side of the bottom plate, positioning openings are formed in the middles of the upper sides of the fixing plates, detachable positioning blocks are arranged inside the positioning openings, installing holes are formed in the middles of the positioning blocks, rotatable discharging rollers are jointly arranged inside the two installing holes, rolling mechanisms are arranged inside the installing holes, and fixing mechanisms are arranged on the fixing plates. The discharging device for the CIPP roll material is reasonable in structural design, capable of cleaning the surface of the CIPP roll material, it is guaranteed that no foreign matter exists on the surface of the CIPP roll material, use of the CIPP roll material is facilitated, the discharging rollers can be rapidly disassembled and assembled, and replacement work of the discharging rollers is facilitated.

Owner:上海潜业市政工程有限公司

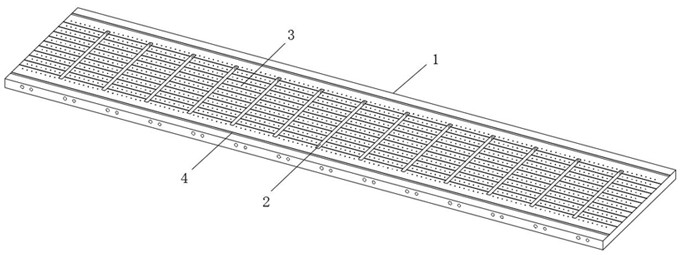

Bottom plate welding device and battery string production equipment

InactiveCN113275687ASmall diameterHigh position coincidence accuracyFinal product manufactureHeating appliancesSilver pasteElectrical battery

The invention provides a welding bottom plate device and battery string production equipment, and relates to the technical field of battery string production. The welding bottom plate device comprises a welding bottom plate body, a plurality of parallel welding wire tail clamping jaw receding grooves are formed in the upper surface of the welding bottom plate body, a plurality of battery piece negative pressure adsorption holes distributed in a rectangular array are formed in the surface of the welding bottom plate body in a penetrating mode, and high-temperature-resistant strong magnet pre-buried grooves are formed in the upper surface of the welding bottom plate body and located on the two sides of the welding wire tail clamping jaw receding groove. According to the bottom plate welding device and the battery string production equipment, a welding wire positioning groove is formed in a welding bottom plate, welding wires are accurately positioned, the position coincidence precision of main grid lines and the welding wires of a battery piece is higher, the width of the main grid lines on the front face and the back face of the battery piece can be smaller, silver paste is saved, the diameter of the welding wires can be reduced, the welding wires with the same weight can be machined to be longer, more battery strings can be welded, and the use cost of the battery piece and the welding wires is greatly reduced.

Owner:深圳光远智能装备股份有限公司

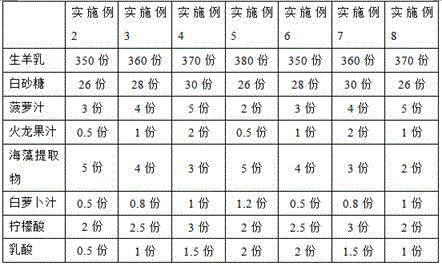

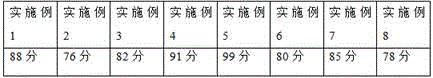

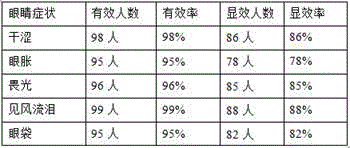

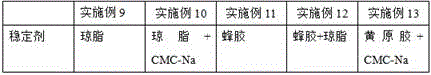

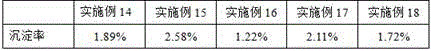

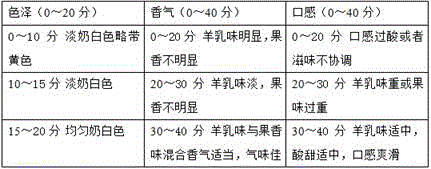

Prepared milk beverage and preparation method thereof

The invention provides a prepared milk beverage and a preparation method thereof. The milk beverage comprises the following raw material components of, by weight, 350-380 parts of raw goat milk, 26-30 parts of white granulated sugar, 2-5 parts of pineapple juice, 0.5-2 parts of dragon fruit juice, 2-5 parts of sea algae extracts, 0.5-1.2 parts of white radish juice, 2-3 parts of citric acid, 0.5-2 parts of lactic acid, 0.25 part of sodium citrate, 0.07 part of acesulfame potassium, 0.6 part of a stabilizer, and 0.3 part of potassium sorbate. The preparation method of the milk beverage comprises the steps of preparation of the sea algae extracts, preparation of the dragon fruit juice, preparation of the white radish juice, preparation of the pineapple juice, weighing of the materials, purification of the milk, blending, homogenizing, high-temperature sterilization, and filling. The milk beverage is free of peculiar smell or foreign matter or layering, and the deposition rate is 1.18-2.58%.

Owner:山东坤泰生物科技有限公司

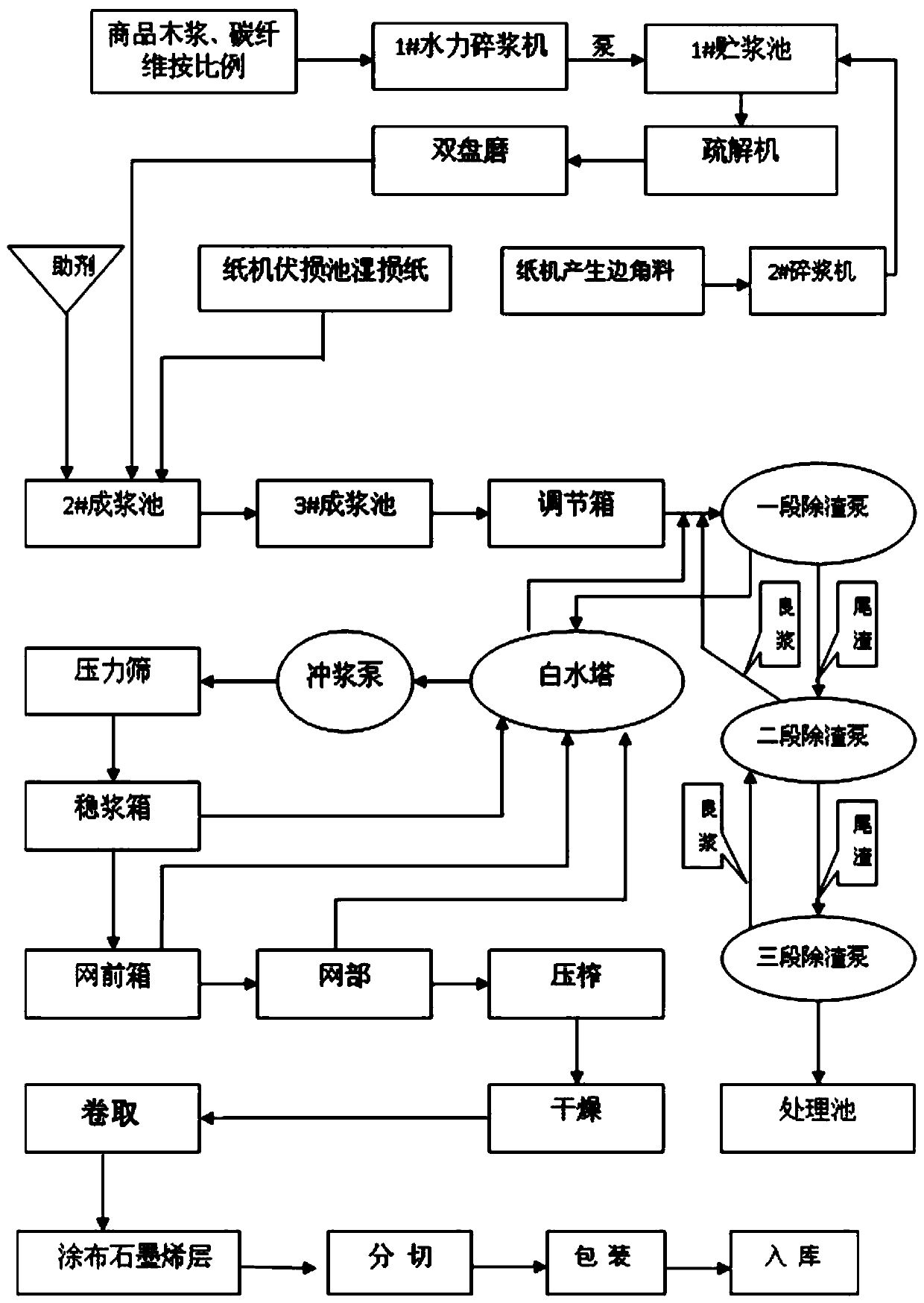

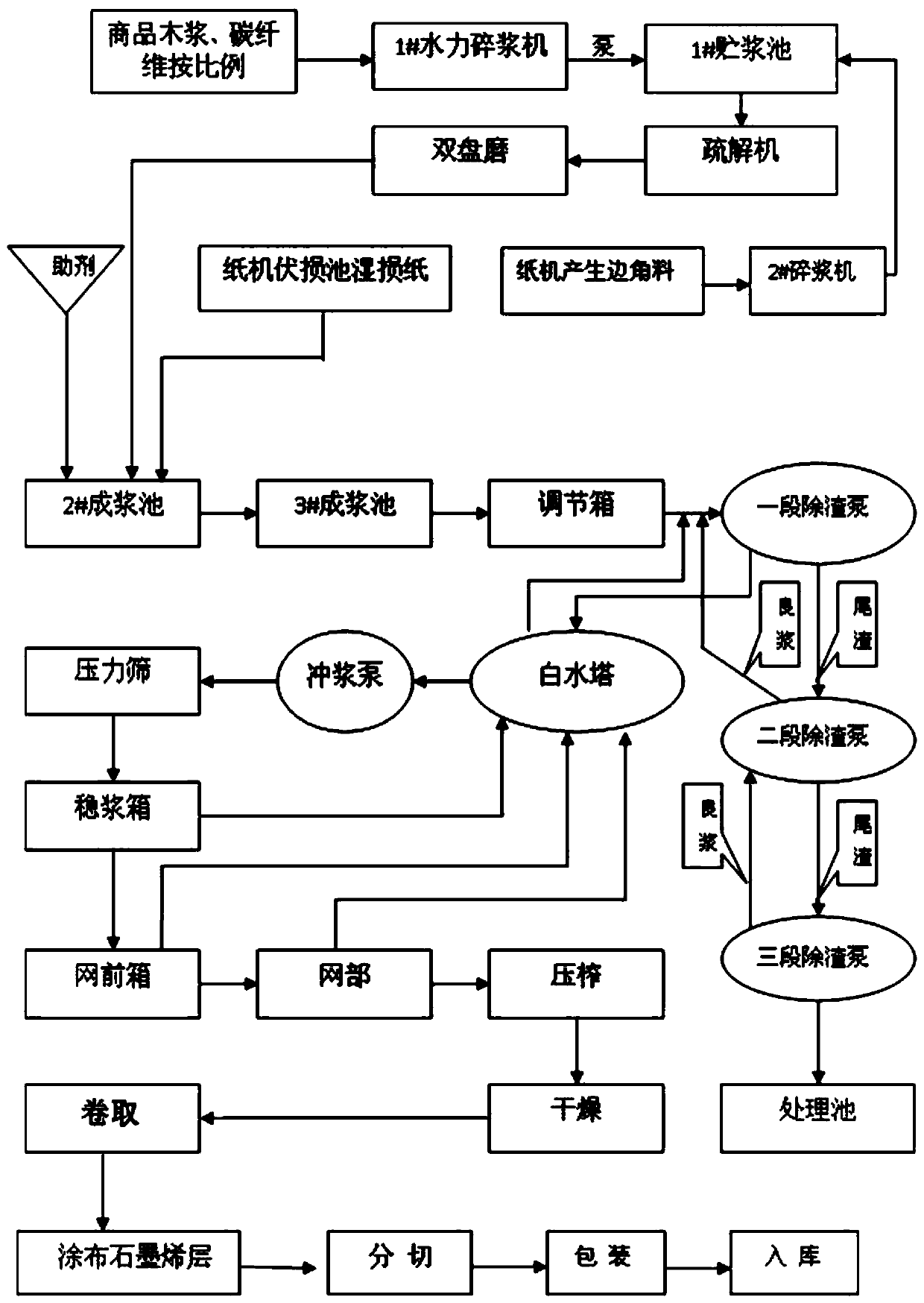

Heating chip material for floor heating, and preparation method and use thereof

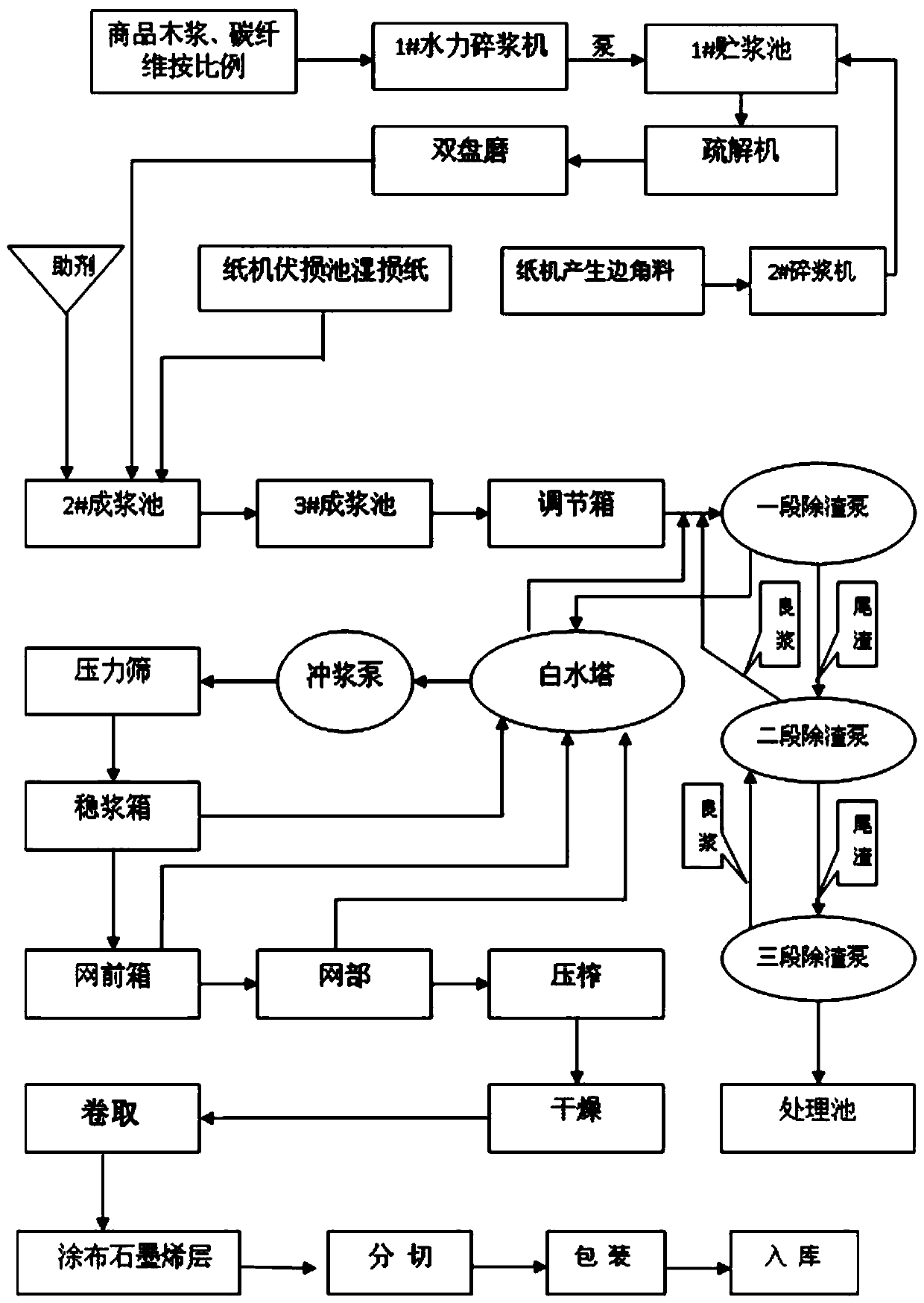

ActiveCN109706781AHeat faster and more evenlyHigh heat conversion efficiencyNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperForeign matterCarbon fibers

A heating chip material for floor heating is provided by combining the floor heating field with a papermaking wet forming technology. Vegetable fibers and carbon fibers are mixed, repulped, defiberedand pulped, and the obtained pulp undergoes residue removal and screening, and then undergoes screen papermaking to obtain a uniform structure morphology, so the surface of obtained paper has the advantages of smoothness, no creases and no foreign matters; and the application of a graphene coating makes floor heating have the characteristics of high heat conversion efficiency, high efficiency, energy saving and fast and uniform heating.

Owner:建滔(佛冈)绝缘材料有限公司

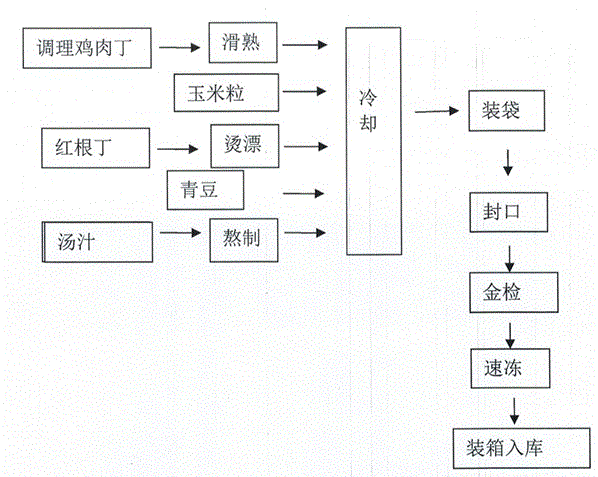

Rainbow chicken pellet processing technology

The invention provides a rainbow chicken pellet processing technology. The technology comprises the following steps that 1, material preparation; 2, raw material pretreatment; 3, soup preparation; 4, bagging and labeling; 5, metal detection; 6, quick freezing; 7, bin packing, labeling and putting in storage. The processing technology is used for making aviation catering food. The rainbow chicken pellets obtained through the technology are easy to process, high in food quality, colorful, delicious, capable of effectively improving appetite of passengers, long in shelf life and good in taste after being heated, and the aviation catering variety is effectively enriched.

Owner:NANJING WEIZHOU FOOD CO LTD

Environment-friendly high-adhesive-force waterborne glass paint

The invention discloses environment-friendly high-adhesive-force waterborne glass paint. The environment-friendly high-adhesive-force waterborne glass paint is prepared from the following components in parts by weight: 30 to 40 parts of modified acrylic resin, 10 to 15 parts of waterborne amino resin, 5 to 10 parts of methyl methacrylate, 5 to 10 parts of an organic solvent, 15 to 20 parts of pure water, 10 to 30 parts of filling, 1 to 2 parts of tributyl citrate, 1 to 2 parts of an adhesive force accelerant, 0.5 to 0.8 part of a flatting agent, 0.5 to 0.8 part of a dispersant, 1 to 1.5 parts of sodium dioctylsulfosuccinate, 0.05 to 0.1 part of glycerol monostearate and 5 to 10 parts of isocyanate. According to the environment-friendly high-adhesive-force waterborne glass paint disclosed by the invention, the adhesive ability and the fastness to water of the glass paint are effectively improved through a reasonable formula design; the materials are safe and environment-friendly and have no toxic organic molecules overflow; a finished product has no bubbles, is not caked and has no foreign matters, no precipitation and stratification phenomena, excellent comprehensive performance and a wide market prospect.

Owner:太仓市美航涂料有限公司

Active lactic acid bacteria beverage and manufacture method thereof

The invention belongs to a diary product field and in particular relates to an active lactic acid bacteria drink and a production method thereof. In the active lactic acid bacteria drink of the invention, water is a base material and components with the following quality content are included: 0.5%-2.0% of beneficial bacteria, 0.8%-1.2% of protein, 1%-5% of glucose, 9%-12% of sucrose and 0.4-0.5% of emulsification stabilizer. The active lactic acid bacteria drink of the invention increases quantity of live bacteria of the lactic acid bacteria and the drink contains both animal protein and plant protein. Besides, through filtering and reasonably collocating strain of the lactic acid bacteria, over 0.1 billion live bacteria exist in the products per milliliter so that a large amount of bacteria can live in intestinal tract and reach a large quantity so as to bring the function of regulating flora and improving immunity.

Owner:广州合诚实业有限公司

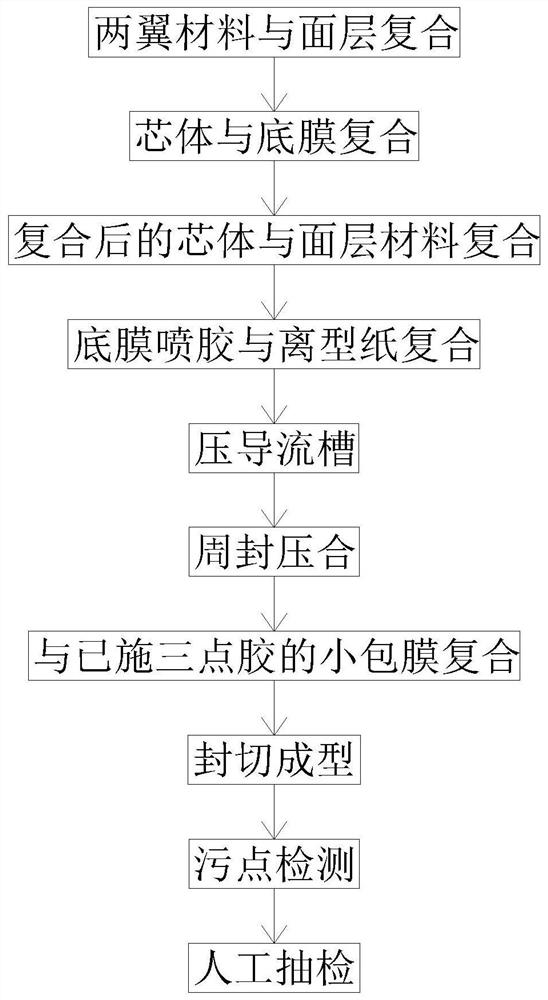

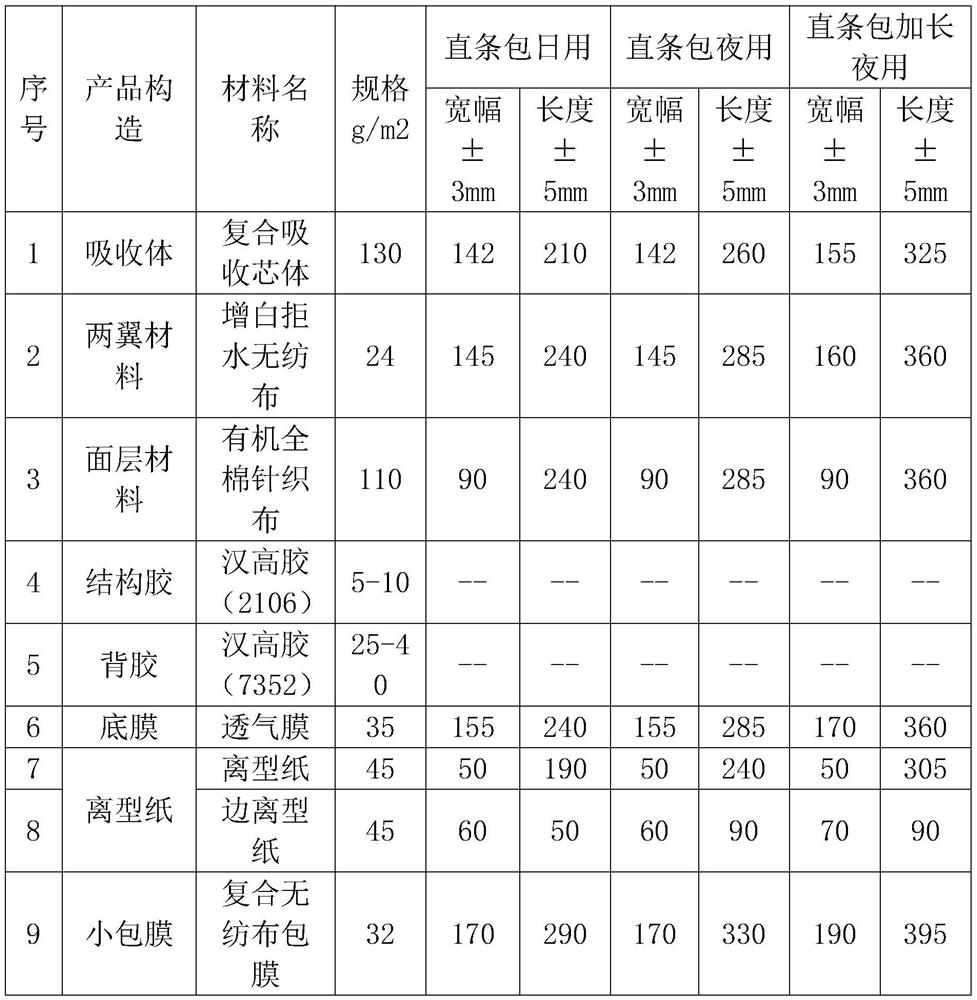

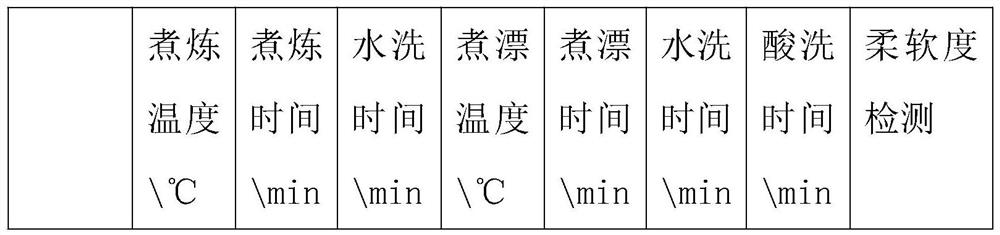

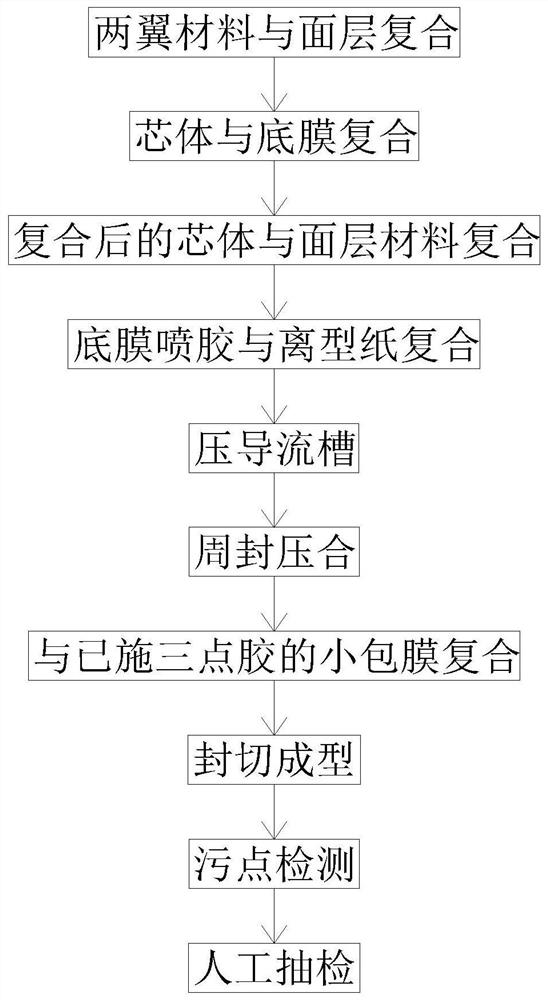

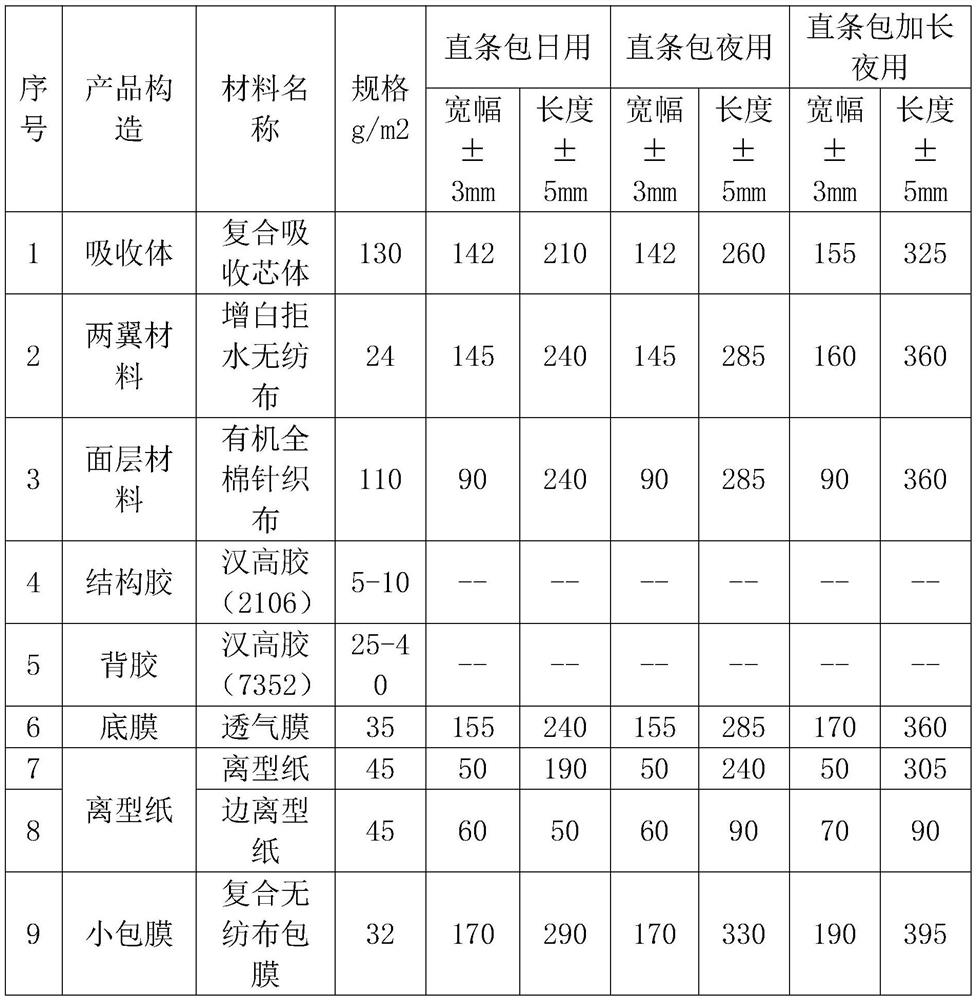

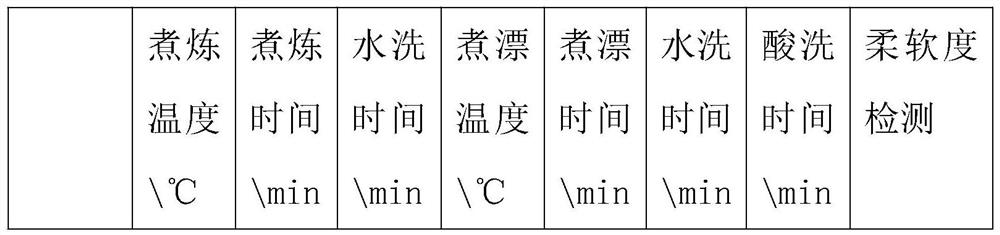

Production method of knitted fabric sanitary towel

ActiveCN111603311AIncrease composite connection strengthIncrease productivitySanitary towelsBaby linensYarnComposite strength

The invention discloses a production method of a knitted fabric sanitary towel, comprising the following specific steps of: compounding two-wing materials and a surface layer: spraying a structural adhesive on the back surfaces of the two-wing materials to be compounded with the surface layer, and feeding into a conveyor belt to wait for compounding with a core body, wherein the surface layer is pure cotton knitted fabric; and compounding the core body and the bottom film: spraying the structural adhesive to the bottom film, and folding the core body for three times. According to the production method of the knitted fabric sanitary towel, the layers are gradually compounded step by step, the composite connection strength of the sanitary towel is improved, the production of the sanitary napkin is layered, the composite strength of the sanitary towel can be improved while the production efficiency is improved. The adopted surface layer is pure cotton knitted fabric woven by 100% pure cotton JC50S all-cotton yarn, the production requirements of the sanitary towel are met through dyeing, finishing and slitting processing, the pure cotton knitted fabric which is sanitary and free of foreign matter, oil contamination and serious bad defects is woven, the use somatosensory feeling of the sanitary towel in direct contact with the skin is improved, a softer surface layer is provided, and the sanitary towel is better used by people.

Owner:北京同仁堂保康科技有限公司

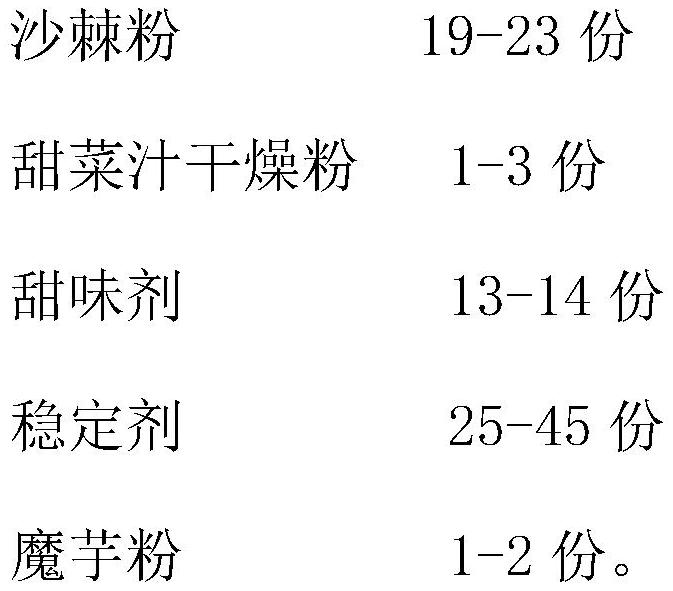

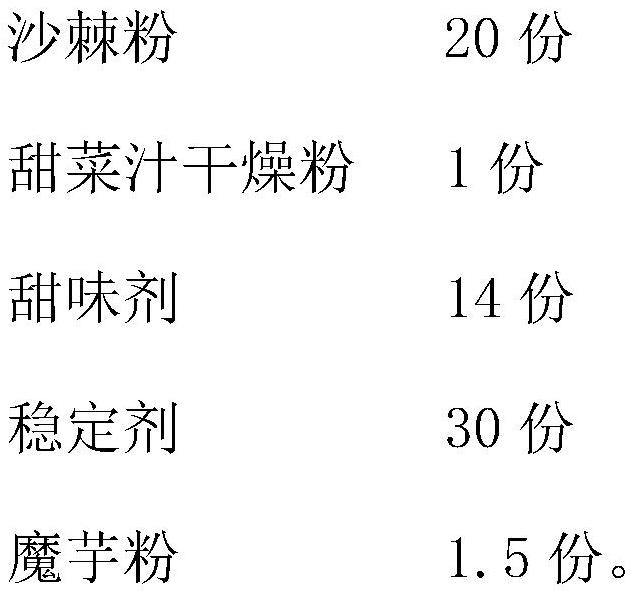

A kind of seabuckthorn solid beverage and its preparation method

ActiveCN109315662BNo foreign matterNo stratificationFood ingredient functionsBiotechnologyBeet juice

Owner:QINGHAI UNIVERSITY

A ground heating heating chip material and its preparation method and application

ActiveCN109706781BHeat faster and more evenlyHigh heat conversion efficiencyNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperGraphene coatingCarbon fibers

The present invention combines the field of floor heating with the wet forming technology of papermaking, and proposes a floor heating heating chip material, which is made by mixing and pulping plant fibers and carbon fibers, dispersing, refining, and then slag removal and screening. Its uniform structure and morphology make the paper surface smooth, wrinkle-free, and foreign matter-free; furthermore, through the application of graphene coating, floor heating is given the characteristics of high heat conversion efficiency, high efficiency and energy saving, faster and more uniform heating.

Owner:建滔(佛冈)绝缘材料有限公司

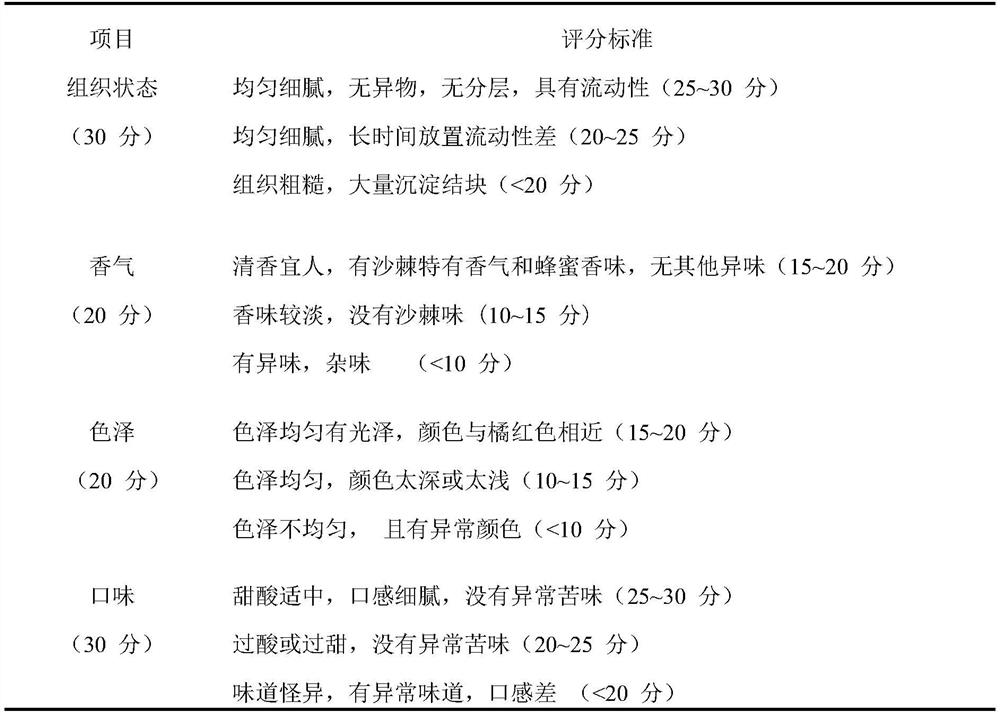

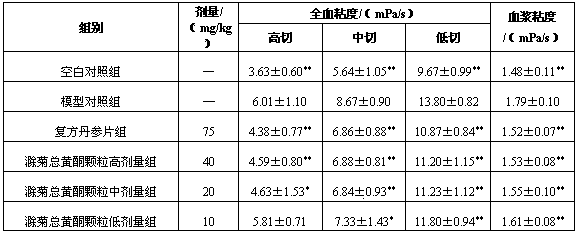

Chuju total flavone granule and its preparation method and application

ActiveCN102973628BNo foreign matterGood molding effectGranular deliveryBlood disorderBiotechnologySucrose

The invention discloses a chrysanthemum total flavone granule, which is made of the following raw materials in the weight ratio: sucrose powder: dextrin: dry extract powder of the total flavonoids of chrysanthemum = 0.5-1.5: 1.5-2.5: 0.5-1.5 . The present invention prepares chrysanthemum total flavonoids into granules. The granules have good formability, properties, particle size, water content, solubility, etc. all meet the requirements, and the quality is controllable and the stability is good. The color changes, the smell is lost, the content of active ingredients decreases, and the color of the item in the soaking process does not turn green. Chuju total flavonoids granules can significantly prolong the coagulation time of rats with cold coagulation and blood stasis syndrome, reduce the length of thrombus in vitro and dry and wet weight, reduce hematocrit, slow down erythrocyte sedimentation rate, and increase serum NO content. The product is easy to drink and carry, easy to store, has no toxic and side effects, and has the characteristics of preventing, treating and improving abnormal blood rheology in rats with blood stasis.

Owner:ANHUI JUTAI CHUJU HERBAGE TECH +1

Preparation type milk-containing beverage with anti-fatigue function, and preparation method thereof

The invention provides preparation type milk-containing beverage with an anti-fatigue function, and a preparation method thereof. The milk-containing beverage comprises the following raw material components in parts by weight: 320 to 400 parts of raw goat milk, 30 to 36 parts of white granulated sugar, 1 to 5 parts of apple juice, 1 to 2 parts of orange juice, 2 to 5 parts of a seaweed extract, 1 to 2 parts of celery juice, 1 to 2 parts of citric acid, 1 to 2 parts of lactic acid, 0.3 part of sodium citrate, 0.08 part of acesulfame potassium, 0.5 part of a stabilizer and 0.3 part of potassium sorbate. The preparation method of the milk-containing beverage comprises the steps of preparing the apple juice, preparing the orange juice, preparing the celery juice, preparing the seaweed extract, weighing the materials, purifying milk, mixing, homogenizing, sterilizing at high temperature and filling. The milk-containing beverage provided by the invention improves the odor of the milk-containing beverage and has higher stability.

Owner:山东坤泰生物科技有限公司

A kind of production method of knitted cloth sanitary napkin

ActiveCN111603311BIncrease composite connection strengthIncrease productivitySanitary towelsBaby linensYarnComposite strength

The invention discloses a production method of a knitted cloth sanitary napkin. The specific steps are as follows: composite the two-wing material with the surface layer: spray structural glue on the back of the two-wing material and composite the surface layer, send it to a conveyor belt and wait for it to be composited with the core body, and the surface layer It is pure cotton knitted fabric; the core body is combined with the bottom film: first spray structural glue on the bottom film, and then fold the core body in three. In the production method of a knitted cloth sanitary napkin according to the present invention, each layer is gradually compounded step by step, which increases the composite connection strength of the sanitary napkin, makes the production of the sanitary napkin have a sense of hierarchy, and can increase production efficiency while increasing production efficiency. The composite strength of large sanitary napkins, the surface layer is pure cotton knitted fabric woven with 100% pure cotton JC50S cotton yarn, and through dyeing, finishing and slitting processing to meet the production needs of sanitary napkins, weaving hygienic, no foreign matter, no oil stains 1. The pure cotton knitted fabric without serious defects improves the feeling of using the sanitary napkin in direct contact with the skin, provides a softer surface layer, and is better for people to use.

Owner:北京同仁堂保康科技有限公司

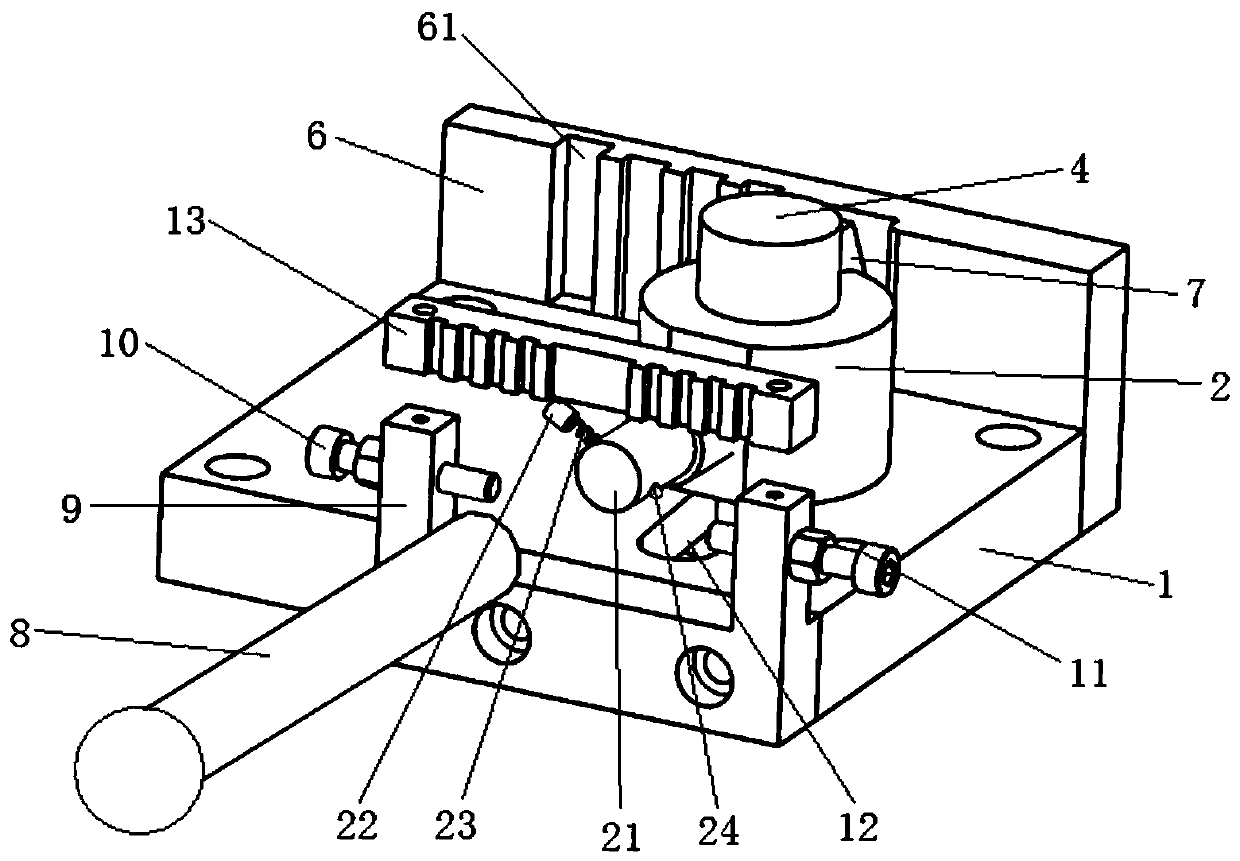

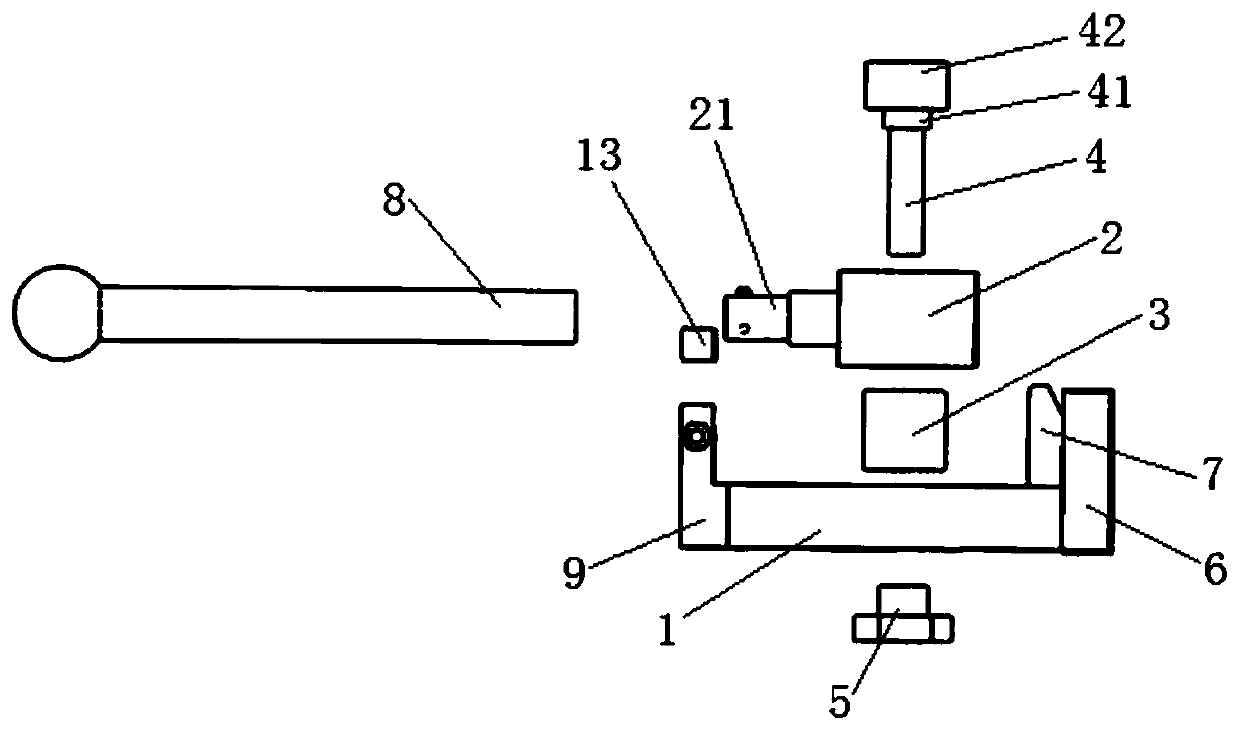

Relay armature deformer

PendingCN111446127AMeet the requirements of armature angle modificationGuaranteed accuracyRelaysControl theoryMechanical engineering

The invention discloses a relay armature deformer. The deformer comprises a base, a rotary deformer, a positioning shaft sleeve, a positioning nail, a guide locking nail, a first limiting plate, a second limiting plate, a rotary rod and an angle limiting frame. The rotary deformer sleeves the positioning shaft sleeve, the base is provided with a sliding notch, and the positioning nail and the guide locking nail extend into the positioning shaft sleeve from an upper portion and a lower portion of the sliding notch to be matched and screwed so that the positioning shaft sleeve is locked on the base. The first limiting plate and the second limiting plate are fixed to one side of the base, a mounting groove is formed between the first limiting plate and the second limiting plate, a heavy vertical piece mounting end of the armature is arranged in the mounting groove, a clamping groove is arranged in the rotary deformer, and a stop piece mounting end of the armature is inserted into the clamping groove. An angle limiting frame is arranged on the other side of the base, a left limiting nail and a right limiting nail are oppositely arranged on the angle limiting frame, a rotating rod is connected with the rotary deformer, and the rotating rod can rotate between the left limiting nail and the right limiting nail to drive the rotary deformer to rotate so as to change an angle between theheavy vertical piece mounting end of the armature and the stop piece mounting end of the armature.

Owner:SHENYANG RAILWAY SIGNAL

A hot blast stove hot blast branch pipe inner lining repair tool and repair method

ActiveCN105369002BNo foreign matterNot affected by low temperatureBlast furnace detailsHeating stovesPatch repairBlowing down

Owner:TIANJIN IRON & STEEL GRP

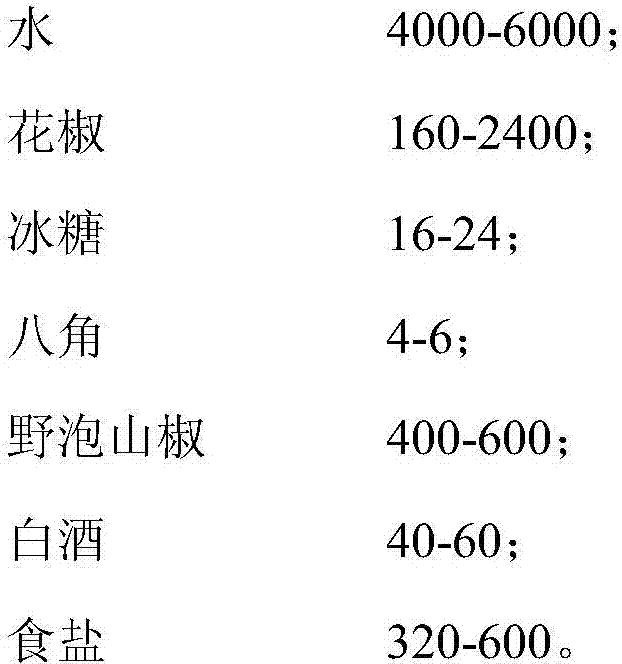

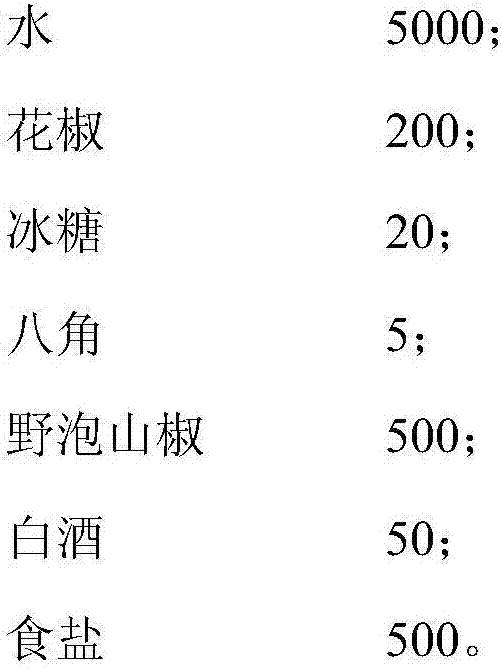

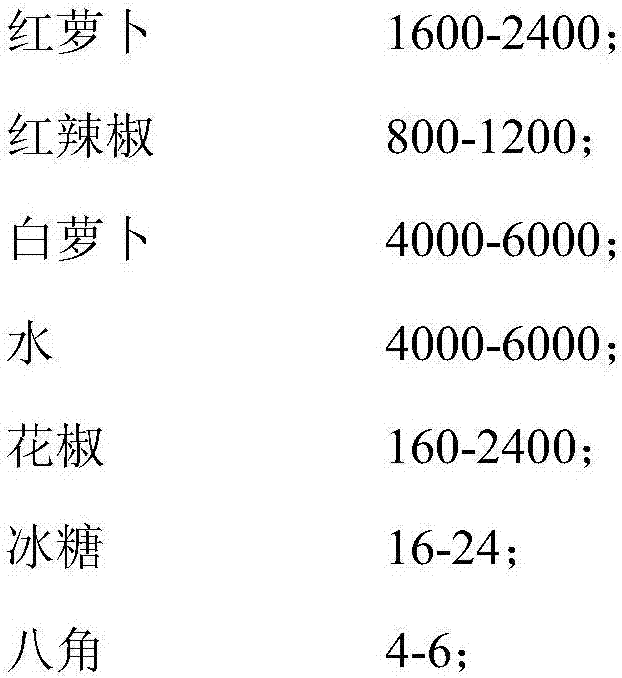

Pickled pepper toadstool

The invention discloses a preparation method for pickled pepper toadstool and relates to the field of food processing. The preparation method comprises the following steps: preparing a soaking solution containing water, pepper, rock candy, anise, wild pickled pepper, white spirit and salt; adding white radish, carrot and red pepper into the soaking solution and performing primary sealing pickling, thereby acquiring a pickled mixture; cleaning the toadstool, airing, putting the aired toadstool into water and boiling, thereby acquiring cooked toadstool; centrifugally treating the cooked toadstool, thereby acquiring the treated toadstool; adding the wild pickled pepper, white vinegar, salt, rock candy and the treated toadstool into the mixture and performing the secondary sealing pickling, thereby acquiring the pickled pepper toadstool. The toadstool treated according to the method disclosed by the invention is characterized in that the nutrition component loss is less, the storage period is long, the toadstool is prevented from going bad, the flavor is excellent, no additive is added, no pesticide residue exists, no exogenous foreign matter exists, the quality is high and the commercial value is high.

Owner:CHONGQING CHUANGSHENG BIOLOGICAL SCI & TECH CO LTD

A kind of polyethylene film with high peeling strength with vmpet non-aluminized surface and preparation method thereof

ActiveCN107903465BGood flexibilityGood adhesionSynthetic resin layered productsPolyesterPolymer science

The invention discloses a polyethylene film with high peeling strength on a non-aluminized surface of VMPET and a preparation method thereof. The polyethylene film comprises the following substances by weight: 5 to 15% of hydrogenated dimer acid / rosin-based polyester polyamide, 2 to 5% of maleic anhydride-grafted polyethylene and 80 to 93% of polyethylene, wherein the hydrogenated dimer acid / rosin-based polyester polyamide is prepared by reacting carboxyl-terminated polyamide with dihydric alcohol; the carboxyl-terminated polyamide is prepared by reacting hydrogenated dimer acid with maleic rosin acid and diamine, a weight ratio of the hydrogenated dimer acid to the maleic rosin acid is 5: 5 to 3: 7, and a ratio of the sum of the mole numbers of carboxyl groups in the hydrogenated dimer acid and the maleic rosin acid to the mole number of amino groups in the diamine is 1: 0.6-0.8; and a ratio of the mole number of hydroxyl groups in the dihydric alcohol to the mole number of carboxyl groups in the carboxyl-terminated polyamide is greater than or equal to 1.8: 1. The prepared polyethylene film in the invention has the advantages of smooth surface, uniform color and no foreign matters, and high peeling strength on the non-aluminized surface of a VMPET film.

Owner:FOSHAN SOUTHERN PACKAGING

A kind of preparation technology of plastic bag lined with carton

InactiveCN106313628BReduce investmentEasy to produceBag making operationsPaper-makingForeign matterQuality level

The invention discloses a carton lining plastic bag preparation technology which comprises the following steps: a low-density high-pressure polyethylene film is selected, the size of the film is determined as demanded, the film is folio, two squares are cut off at two angles on one side of the line made by folding according to the length of one half of the bottom width of a plastic inner bag, the cut-off film is opened and is erected along the cut-off lines to form a three-dimensional square bag shape, the horizontal sides and central vertical sides at the bottoms of two side faces are sealed, and eyelet work is carried out on long sides and narrow sides of the inner bag as demanded. According to the invention, the sealing sides of the carton lining plastic bag are decreased to four sides, so that the production processes are reduced, the raw material is saved, investment in labor force and the production cost are reduced, and the production efficiency is improved; and in addition, the product is uniform and transparent in color and luster, is free from extraneous odor and foreign matter, and is higher in quality level.

Owner:昆明新鑫润丰塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com