A kind of preparation technology of plastic bag lined with carton

A preparation process and technology of plastic bags, applied in the field of plastic bags, can solve the problems of difficult plastic molding, low transparency and high production cost, and achieve the effects of reducing labor input, uniform and transparent color, and high quality level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The preparation steps of carton lined plastic bags are as follows:

[0020] 1. Material selection: Low-density high-pressure polyethylene PE-LD film is selected;

[0021] 2. Determine the specification: determine the size of the required film as the standard specification according to the demand;

[0022] 3. Fold in half: fold the standard specification film in half;

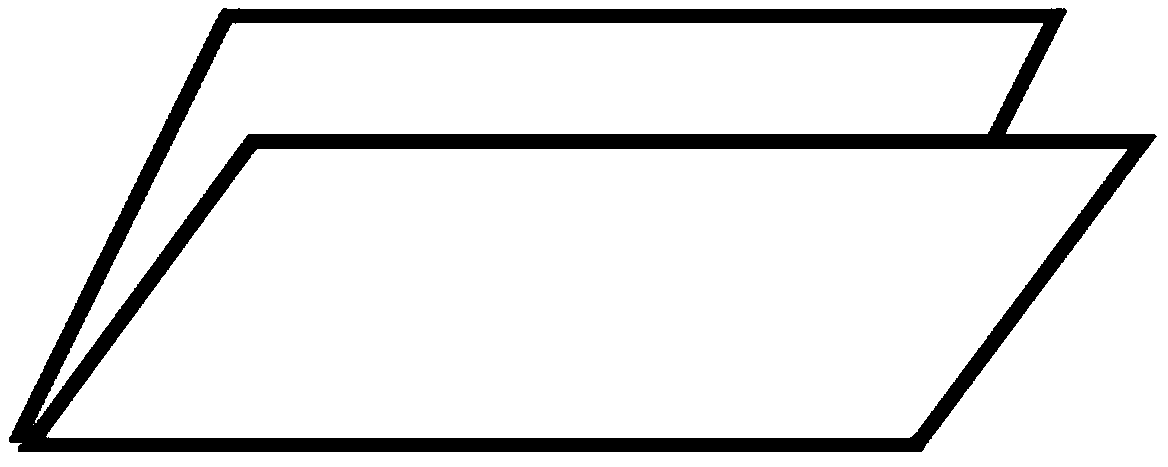

[0023] 4. Cutting: According to the length of half the width of the bottom of the plastic inner bag, cut two squares on the two corners of the side of the crease;

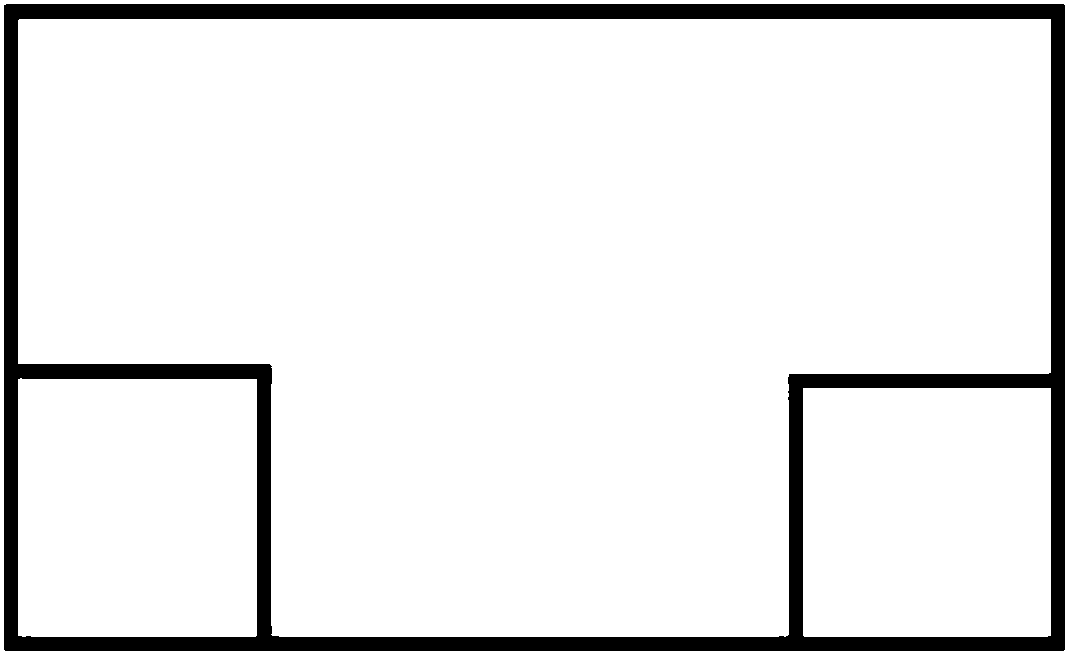

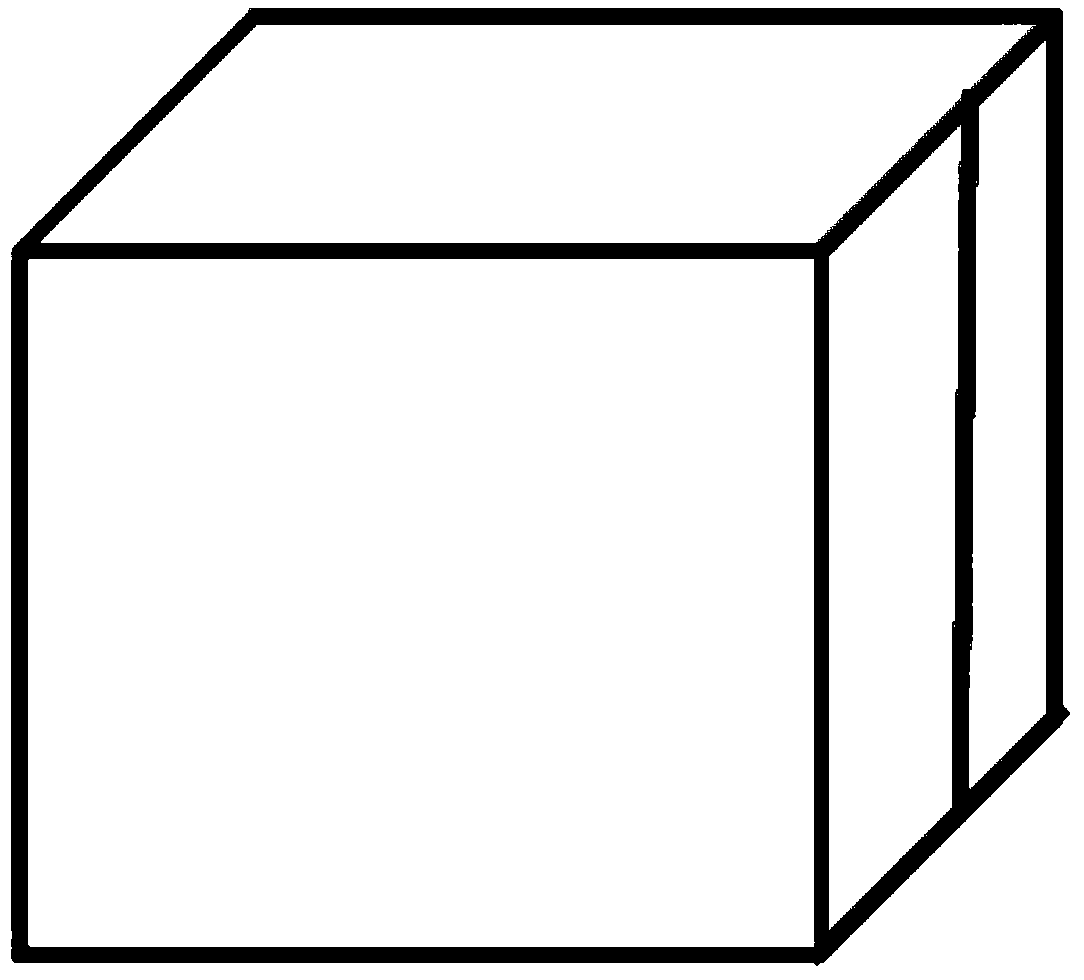

[0024] 5. Modeling: the film after opening and cutting will be erected respectively along the cutting edge, so that it presents a three-dimensional square bag shape;

[0025] 6. Sealing: seal the bottom horizontal and central vertical sides of both sides;

[0026] 7. Perforation: The holes on the long side of the inner bag are distributed in 3 rows and 4 rows, and the holes on the narrow side are distributed in 3 rows and 2 rows; the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com