Repair tooling of hot-blast branch pipe lining of hot-blast furnace and repair method thereof

A technology of hot blast branch pipes and hot blast stoves, which is applied in the field of hot blast stove repairs in actual production. It can solve the problems of heavy tonnage of hot blast valves, difficulty in dismantling, installing and hoisting of valves, and complex surrounding environment, so as to reduce difficulty, improve operating efficiency, and ensure safety. sex assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

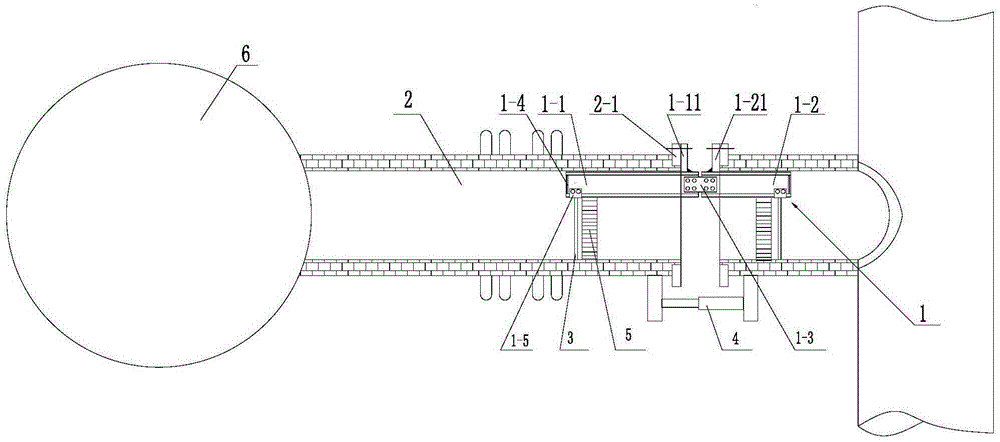

[0026] see figure 1 , a tool for repairing the inner lining of the hot blast branch pipe of the hot blast stove, comprising a support track beam 1, the support track beam adopts a split composite structure, including a left support track beam 1-1 and a right support track beam 1-2, the left support track beam 1-1 and the right support track beam 1-2 are connected to form an integral support track beam 1 through a detachable connecting plate 1-3, and limit blocks 1-4 are provided at both ends of the support track beam for the purpose of placing Break away from the supporting track beam during driving; the connecting ends of the left supporting track beam 1-1 and the right supporting track beam 1-2 are respectively provided with hoisting plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com