Production method of knitted fabric sanitary towel

A production method and technology for knitted fabrics, applied in the field of invention, can solve the problems of insufficient composite strength, pure cotton, and no maintenance effect on women's private parts, and achieve the effects of increasing the composite connection strength and improving the feeling of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

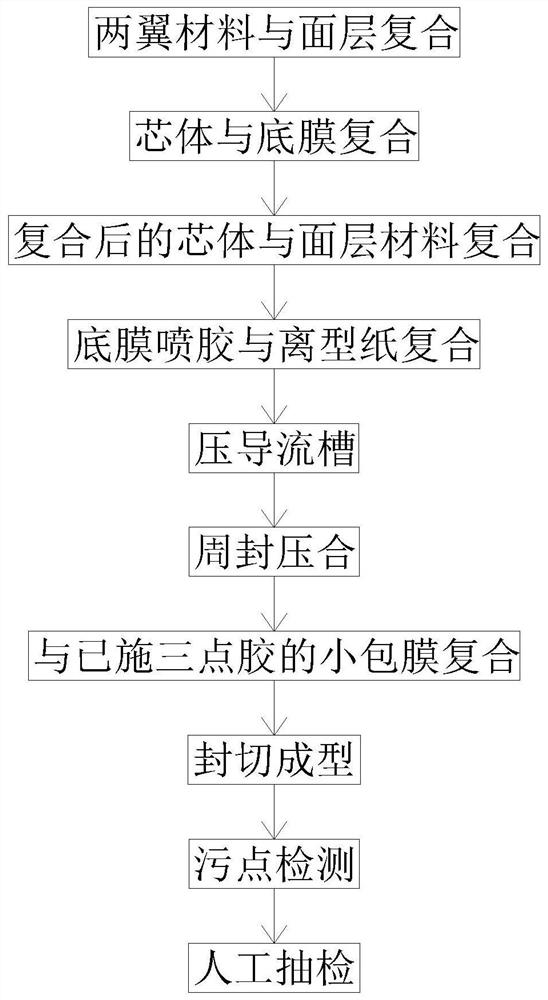

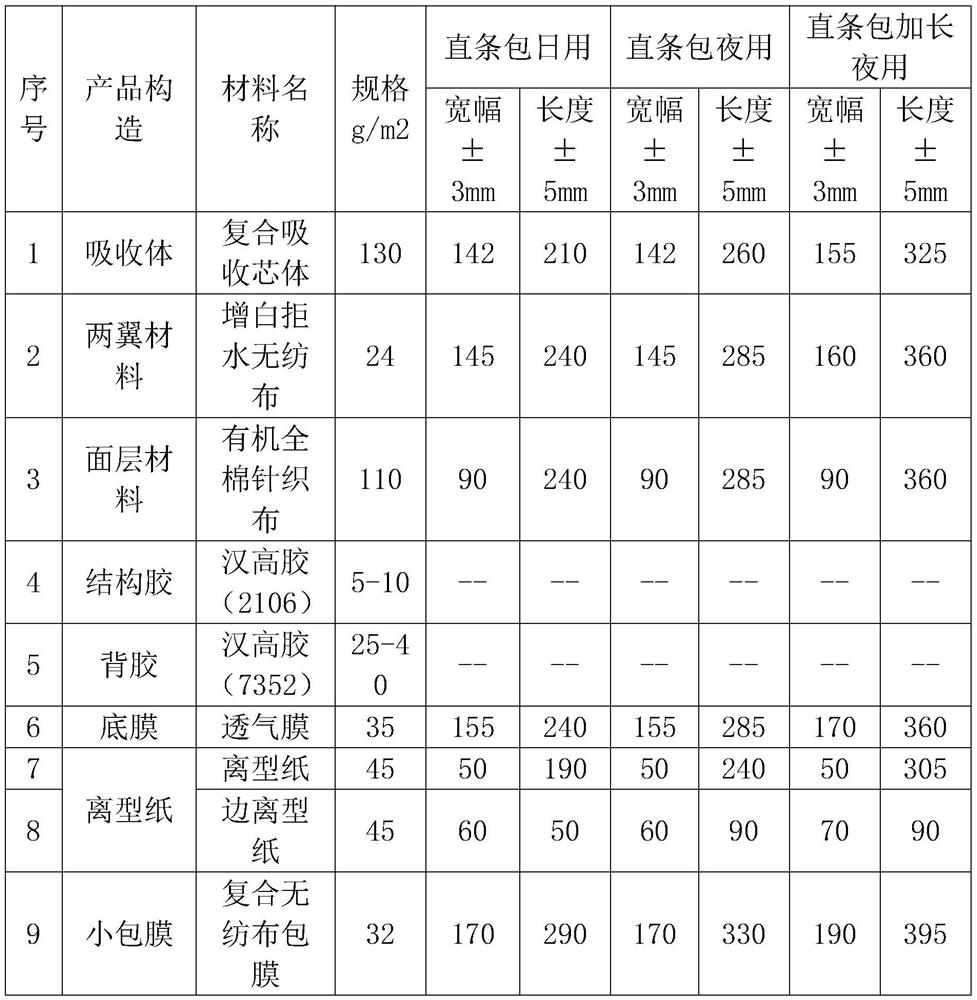

[0042] A kind of production method of knitted cloth sanitary napkin, concrete steps are as follows:

[0043] (1) Composite of the two-wing material and the surface layer: spray structural glue on the back of the two-wing material and compound the surface layer, send it to the conveyor belt and wait for it to be compounded with the core body, and the surface layer is pure cotton knitted fabric;

[0044] (2) Composite core and bottom film: first spray structural glue on the bottom film, then fold the core in three, and compound the core with the bottom film that has been sprayed with structural glue through the conveyor belt. The core is absorbent paper. The bottom film is the perforated film;

[0045] (3) Composite core body and surface layer material: send the core body compounded with the base film in step (2) to the next glue spray gun to spray structural glue by the conveyor belt, and process it with step (1) The surface material is compounded, and the structural glue spra...

Embodiment 2

[0054] A kind of production method of knitted cloth sanitary napkin, concrete steps are as follows:

[0055] (1) Composite of the two-wing material and the surface layer: spray structural glue on the back of the two-wing material and compound the surface layer, send it to the conveyor belt and wait for it to be compounded with the core body, and the surface layer is pure cotton knitted fabric;

[0056] (2) Composite core and bottom film: first spray structural glue on the bottom film, then fold the core in three, and compound the core with the bottom film that has been sprayed with structural glue through the conveyor belt. The core is absorbent paper. The bottom film is the perforated film;

[0057] (3) Composite core body and surface layer material: send the core body compounded with the base film in step (2) to the next glue spray gun to spray structural glue by the conveyor belt, and process it with step (1) The surface layer materials are compounded, and the structural g...

Embodiment 3

[0066] A kind of production method of knitted cloth sanitary napkin, concrete steps are as follows:

[0067] (1) Composite of the two-wing material and the surface layer: spray structural glue on the back of the two-wing material and compound the surface layer, send it to the conveyor belt and wait for it to be compounded with the core body, and the surface layer is pure cotton knitted fabric;

[0068] (2) Composite core and bottom film: first spray structural glue on the bottom film, then fold the core in three, and compound the core with the bottom film that has been sprayed with structural glue through the conveyor belt. The core is absorbent paper. The bottom film is the perforated film;

[0069] (3) Composite core body and surface layer material: send the core body compounded with the base film in step (2) to the next glue spray gun to spray structural glue by the conveyor belt, and process it with step (1) The surface layer materials are compounded, and the structural g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com