A ground heating heating chip material and its preparation method and application

A heating chip and floor heating technology, which is applied in the field of floor heating heating materials, can solve the problems of residential temperature and human discomfort, and achieve more uniform heating, faster heating, and higher heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A floor heating heating chip material, the fiber raw material composition of the floor heating heating chip material is: commercial wood pulp 92%, carbon fiber 8%; the quantitative value of the material is 28 g / m²; thickness: 55 μm; the material is mainly used for floor heating The heating chip material has the characteristics of high heat conversion efficiency, high efficiency and energy saving, and faster and more uniform heating; the appearance of the material shows the advantages of uniform fiber structure, smooth paper surface, no wrinkles, and no foreign matter.

[0024] The commercial wood pulp consists of 50% bleached coniferous wood pulp and 42% bleached eucalyptus wood pulp.

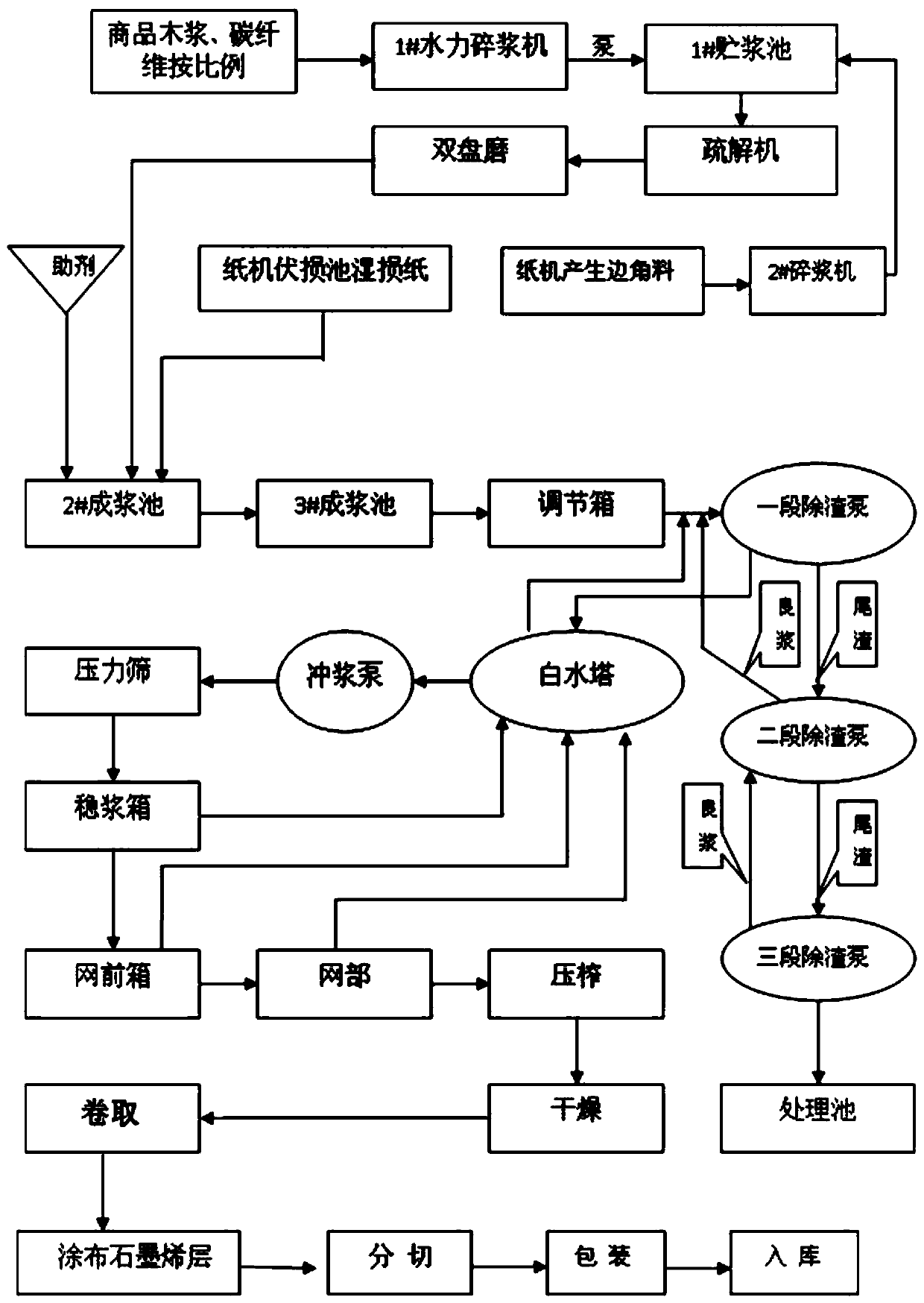

[0025] Such as figure 1 As shown, the preparation method of the floor heating heating chip material includes the following preparation steps:

[0026] (1) Weigh the commercial wood pulp and carbon fiber according to the ratio and mix them into the 1# hydraulic pulper for pulping, and th...

Embodiment 2

[0037] A floor heating heating chip material, the fiber raw material composition of the floor heating heating chip material is: 95% commercial wood pulp, 5% carbon fiber; the basis weight of the material is 25 g / m²; thickness: 58 μm; the material is mainly used for floor heating The heating chip material has the characteristics of high heat conversion efficiency, high efficiency and energy saving, and faster and more uniform heating; the appearance of the material shows the advantages of uniform fiber structure, smooth paper surface, no wrinkles, and no foreign matter.

[0038] The commercial wood pulp is composed of 50% bleached coniferous wood pulp and 45% bleached eucalyptus wood pulp.

[0039] Such as figure 1 As shown, the preparation method of the floor heating heating chip material comprises the following preparation steps:

[0040] (1) Weigh the commercial wood pulp and carbon fiber according to the ratio and mix them into the 1# hydraulic pulper for pulping, and then...

Embodiment 3

[0051]A floor heating heating chip material, the fiber raw material composition of the floor heating heating chip material is: 94% commercial wood pulp, 6% carbon fiber; the quantitative value of the material is 31 g / m²; the thickness: 52 μm; the material is mainly used for floor heating The heating chip material has the characteristics of high heat conversion efficiency, high efficiency and energy saving, and faster and more uniform heating; the appearance of the material shows the advantages of uniform fiber structure, smooth paper surface, no wrinkles, and no foreign matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com