How to make led display module

A technology of LED display screen and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., which can solve the problems of poor uniformity of ink color of laminated film layer, etc., and achieve the effect of high ink color consistency and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

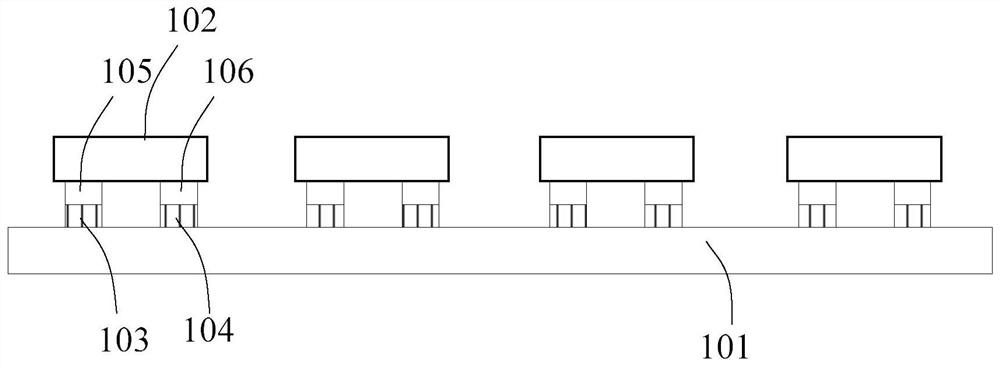

[0042] Such as Figure 1 ~ Figure 3 and Figure 8 ~ Figure 10 As shown, the present embodiment provides a method for manufacturing an LED display module, and the method includes:

[0043] Such as figure 1 As shown, step 1) is first performed, providing a PCB substrate or glass substrate 101 , and flip-chiping the Mini LED chip 102 on the PCB substrate or glass substrate 101 .

[0044]The PCB substrate or glass substrate 101 includes a first surface and a second surface, the first surface is formed with electrodes for connecting with the Mini LED chip 102, and the second surface has a connecting portion for connecting with the driver chip . The PCB substrate or glass substrate 101 can be a single-layer or multilayer board, and there are interconnection lines inside the PCB substrate or glass substrate 101, and the electrodes include a first electrode 103 and a second electrode 104, and the first electrode 103 can be Positive or negative, the second electrode 104 can be nega...

Embodiment 2

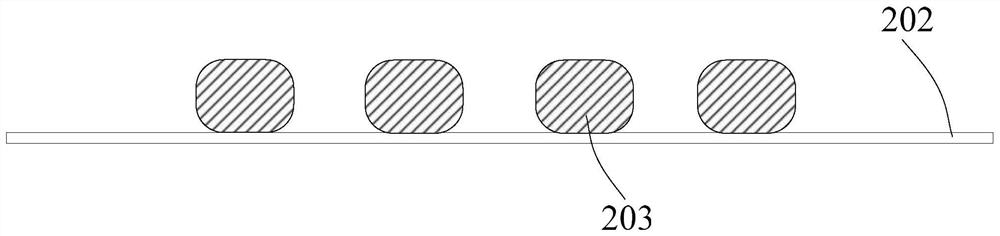

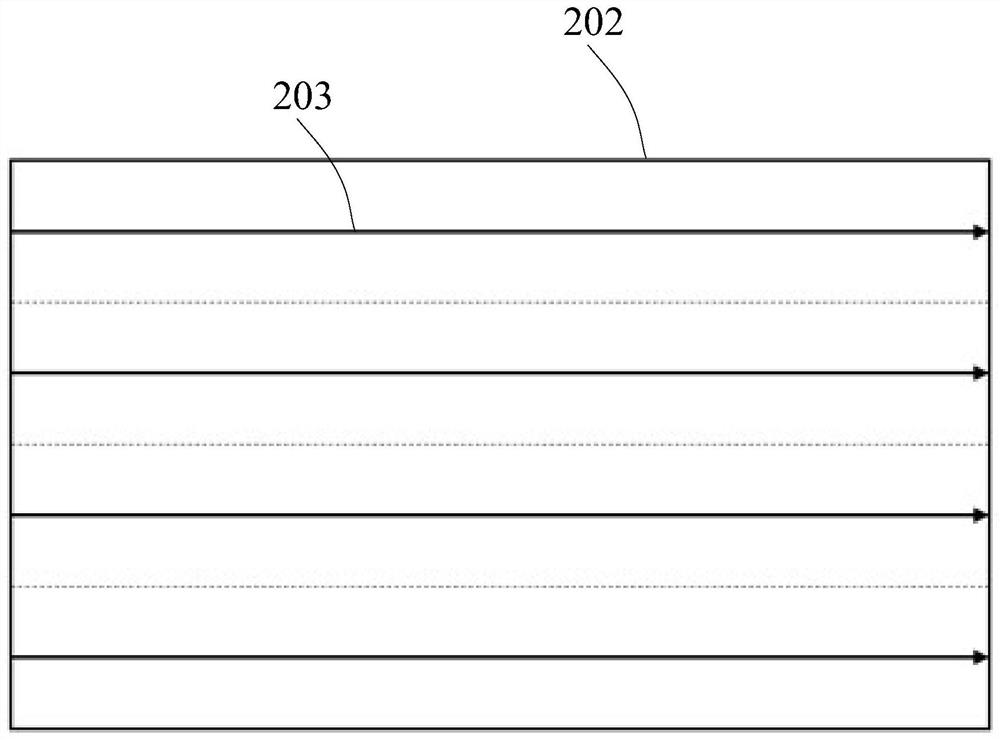

[0056] Such as Figure 1~2 , Figure 4 and Figure 8 ~ Figure 10 As shown, this embodiment provides a method for manufacturing an LED display module, the basic steps of which are as in Embodiment 1, where the difference from Embodiment 1 lies in:

[0057] The shape of the dispersed-coated laminated film material 203 is a line segment array pattern, and the line segment array pattern is a plurality of interlaced line segments in a net shape.

[0058] In a specific implementation process, the line segment array pattern is a plurality of line segments interlaced in a rectangular network, such as Figure 4 As shown, the coating area is divided into several equal sub-regions in the horizontal and vertical directions, such as m parts in the horizontal direction, m≥1, n parts in the vertical direction, n≥1, m and n may or may not be equal. A glue applicator is used to coat the lamination material 203 in the transverse direction, and the coating path is a straight line connecting t...

Embodiment 3

[0060] Such as Figure 1~2 , Figure 5 and Figure 8 ~ Figure 10 As shown, this embodiment provides a method for manufacturing an LED display module, the basic steps of which are as in Embodiment 1, where the difference from Embodiment 1 lies in:

[0061] The shape of the dispersed-coated lamination material 203 is a line segment array pattern, and the line segment array pattern is a spirally bent line segment.

[0062] In a specific implementation process, such as Figure 5 As shown, starting from the center of the coating area, the lamination material 203 is coated spirally to the periphery. The pressure film material 203 can also be coated in a spiral shape from the periphery to the center point of the coating area. In the process of coating the pressing film material 203, the glue amount of the pressing film material 203 can be adjusted according to the position of the spiral part, for example, the amount of the pressing film material 203 located in the central area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com