LED chip, display screen module and display screen

A LED chip and display technology, applied in optics, instruments, electrical components, etc., can solve the problems of low brightness ink color consistency, long calibration time, and heavy sorting workload on the display screen, achieve good ink color consistency, reduce Brightness, the effect of reducing light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

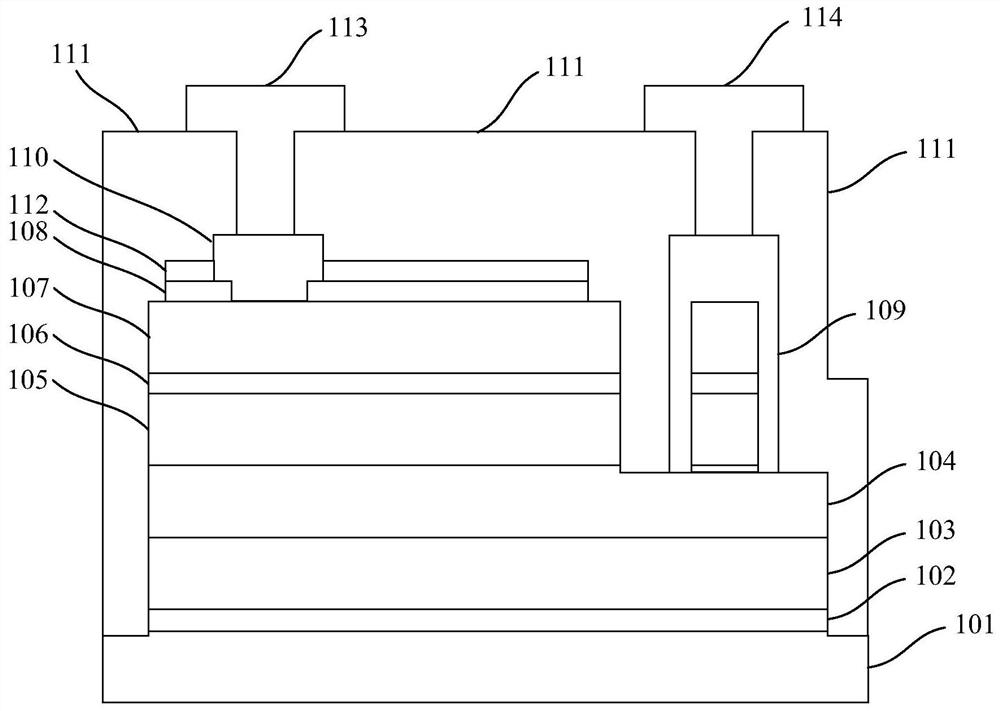

[0051] Such as figure 1 As shown, this embodiment provides an LED chip, the LED chip is used in an LED display module, and the LED chip includes a substrate 101, a buffer layer 102, an intrinsic semiconductor layer 103, an N-type semiconductor layer 104, and a light emitting layer. 105. Electron blocking layer 106, P-type semiconductor layer 107, ITO transparent conductive layer 108, anti-reflection layer 112, steps, first electrode, second electrode and passivation layer 111, wherein the light emitting layer 105 is located on the N above the P-type semiconductor layer 104, the P-type semiconductor layer 107 is located above the light-emitting layer 105, the step runs through the P-type semiconductor layer 107 and the light-emitting layer 105, and exposes the N-type semiconductor layer 104 part surface.

[0052]For example, the substrate 101 can be a sapphire substrate, the N-type semiconductor can be an N-type gallium nitride layer, the light-emitting layer 105 can be a mult...

Embodiment 2

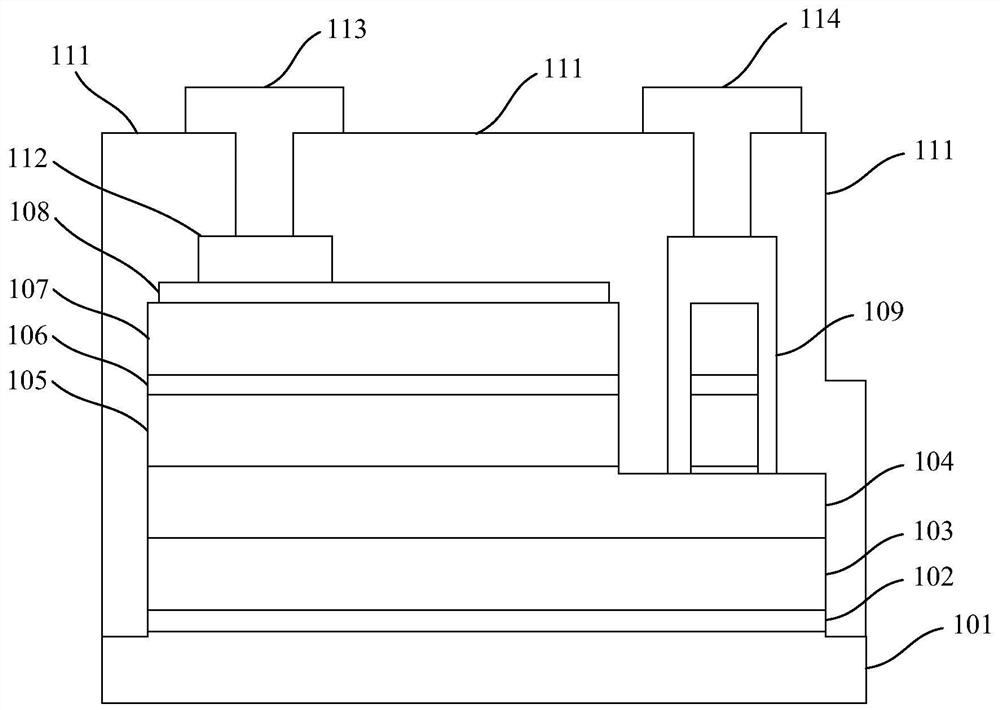

[0061] Such as figure 2 As shown, this embodiment provides an LED chip, and the LED chip is used in an LED display module. The basic structure of the LED chip is as in Embodiment 1, wherein the difference from Embodiment 1 is that the first electrode Including a first bottom electrode 110 and a first outer electrode 113, the second electrode includes a second bottom electrode 109 and a second outer electrode 114, and the anti-reflection layer 112 is used as the first bottom electrode 110 to connect the The ITO transparent conductive layer 108 and the first outer electrode 113 . In this embodiment, the anti-reflection layer 112 is used as the first bottom electrode 110, which can effectively save process steps and reduce process costs.

Embodiment 3

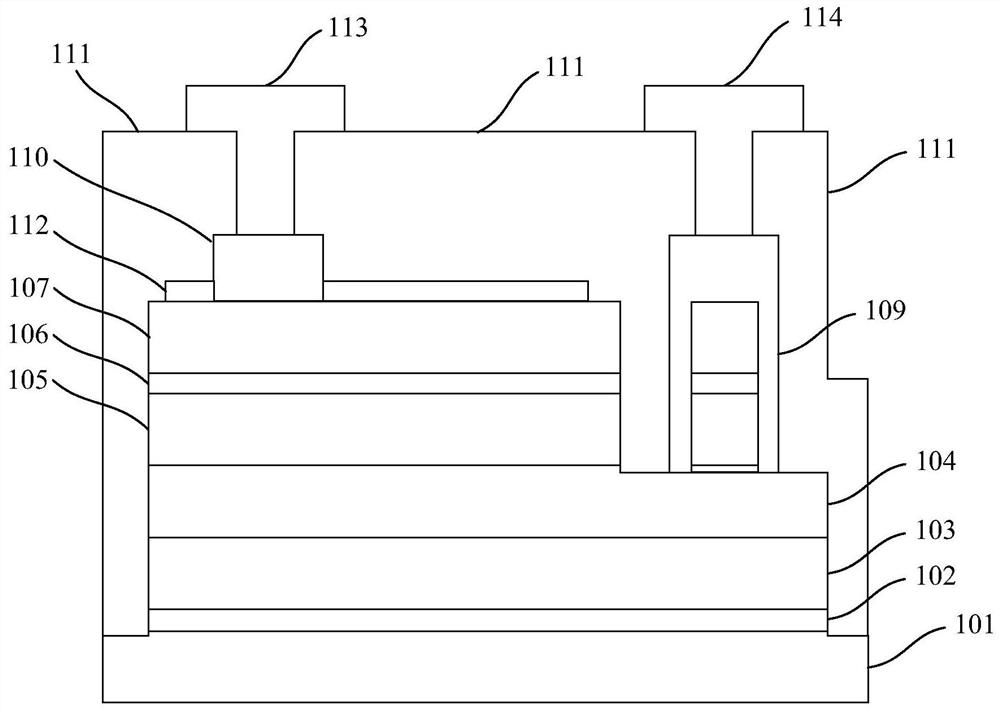

[0063] Such as image 3 As shown, this embodiment provides an LED chip, and the LED chip is used in an LED display module. The basic structure of the LED chip is as in Embodiment 1, wherein the difference from Embodiment 1 is that the anti-reflection layer 112 includes a low-reflectivity conductive material, and the anti-reflection layer 112 forms an ohmic contact with the P-type semiconductor layer 107 to simultaneously serve as a current spreading layer, and the first electrode communicates with the P-type semiconductor layer 107 through the anti-reflection layer 112 The semiconductor layer 107 is electrically connected. The LED chip of this embodiment does not need to make an additional ITO transparent conductive layer 108, and the anti-reflection layer 112 directly forms an ohmic contact with the P-type semiconductor layer 107, which not only plays the role of current diffusion, but also plays the role of reducing light reflection, which can effectively simplify the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com