Battery packaging method and battery

A packaging method and battery technology, applied in the field of device processing, can solve the problems of low bonding strength between polymer and electrode metal, can not better ensure safety, can not guarantee battery safety, etc., to improve applicability and practicability, Effects of increased strength, strength and torsion, and increased air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0034] 本申请实施例所提供的电池的封装方法可以应用于各类电池的封装,比如锂电池、干电池、燃料电池等电池。且本申请实施例中所指的封装是对电池的金属外壳与电极进行封接,封接好的电池才能进行使用。

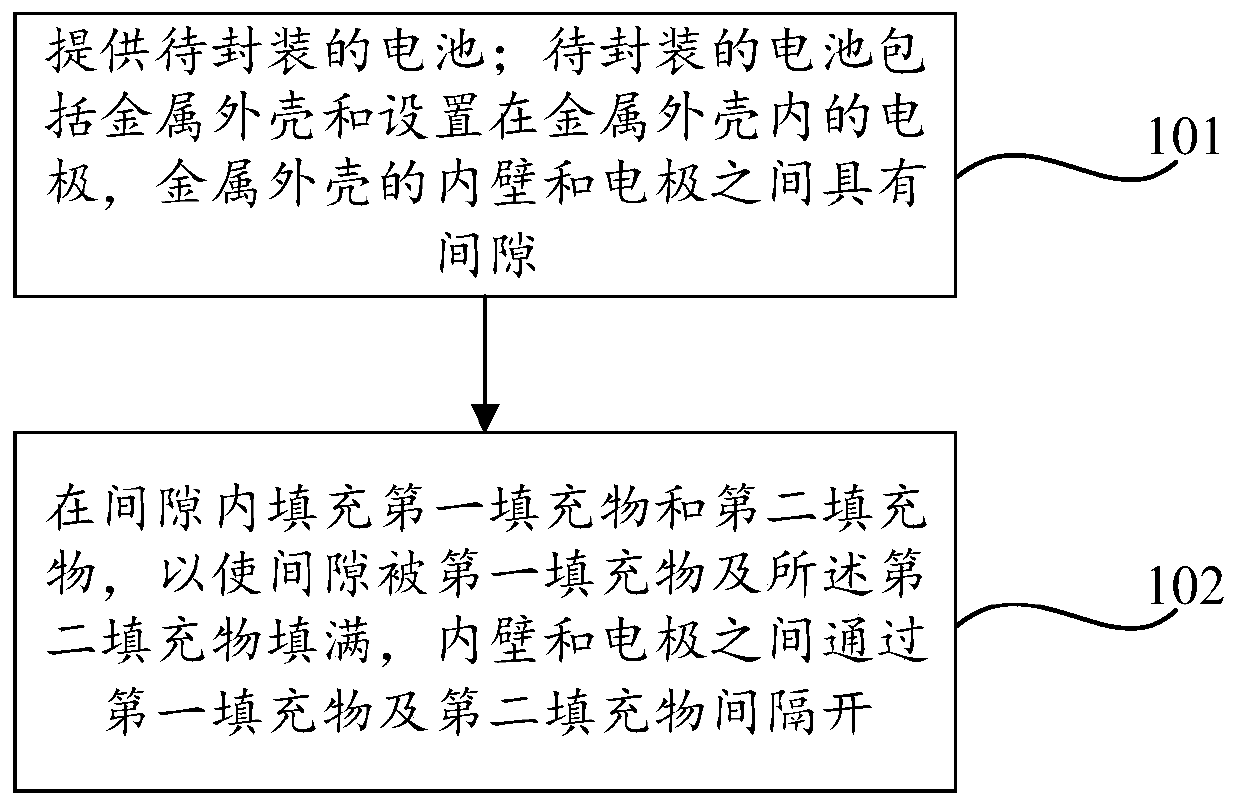

[0035] 接下来请参照 figure 1 ,为本申请实施例提供的电池的封装方法的流程图,该封装方法包括:

[0036] 步骤101:提供待封装的电池;待封装的电池包括金属外壳和设置在金属外壳内的电极,金属外壳的内壁和电极之间具有间隙。

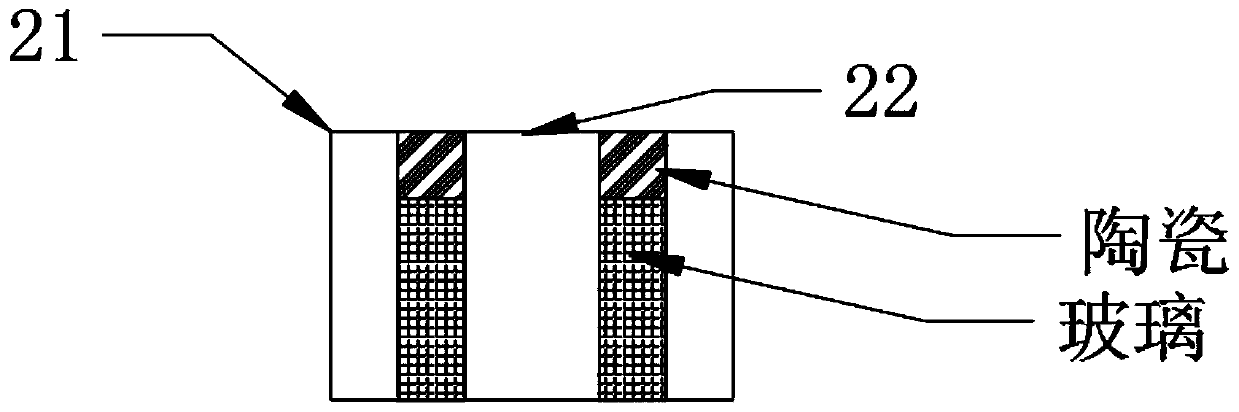

[0037] 步骤102:在间隙内填充第一填充物和第二填充物,以使间隙被第一填充物及所述第二填充物填满,内壁和电极之间通过第一填充物及第二填充物间隔开。其中,第一填充物和第二填充物二者之一为陶瓷,另一者为玻璃。

[0038] 在本申请实施例中,利用玻璃和陶瓷作为填充物来对金属外壳与电极之间的间隙进行填充,与现有技术相比,玻璃和金属的结合能够保证电池的气密性;陶瓷提高扭力和抗冲击强度,还能够保护电池在受到高温时可以充分绝缘。因此,通过该封装方法对电池进行封装能够保证电池在高温情况下的绝缘性,延长电池寿命,保证电池的安全性,并且能够使该电池能够应用于有扭力要求的器件或者设备,提高电池的适用性和实用性。

[0039] 接下来对步骤101和步骤102的详细实施方式进行介绍。

[0040] 在步骤101中,待封装的电池包括金属外壳和设置在金属外壳内的电极,对于电极,通常包括两个电极端子,两个电极端子一般为金属端子。当没有进行封装时,电极与金属外壳的内壁之间具有间隙。

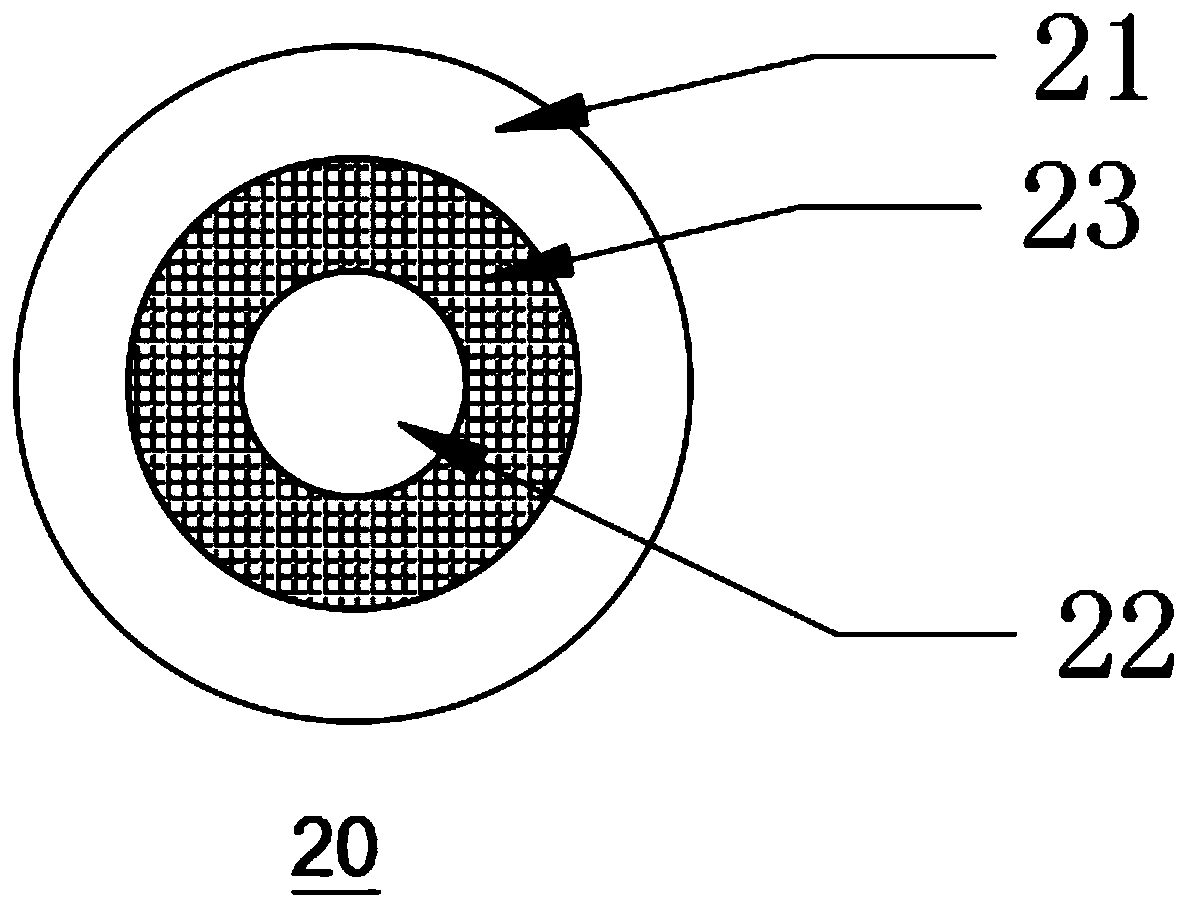

[0041] 对于电极和金属外壳来说,通常为圆柱形,金属外壳可以两端都是开口的,也可以一端开口,一端封闭。当与金属外壳同为圆柱形但底面积比金属外壳小的电极设置在金属外壳内部时,两者之间形成的间隙可以是环形的间隙(即两端都是开口的情况),也可以是U形的间隙(即一端开口,一端封...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com