Paper surface gypsum fireproof color steel plate and its preparation process

A paper-faced gypsum board and paper-faced gypsum technology, applied in the field of fireproof steel plates, can solve problems such as bursting, unsatisfactory fire resistance of steel plates, and weak fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

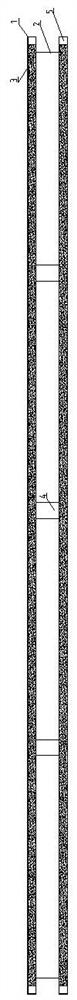

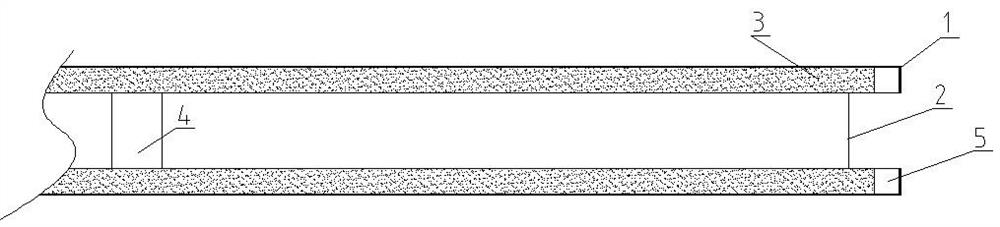

[0029] Such as figure 1 and figure 2 As shown, the paper-faced gypsum fireproof color steel plate and its preparation process, through its structural design, material selection and improvement of preparation process, can improve the fire prevention effect and heat bearing capacity.

[0030] Paper-faced gypsum fireproof color steel plate, said color steel plate includes desulfurization paper-faced gypsum board 3, galvanized steel plate 2, and two parallel color-coated steel plates 1; wherein the inner surfaces of the two parallel color-coated steel plates 1 are provided with desulfurization paper Gypsum boards 3, two desulfurized paper-faced gypsum boards 3 are arranged at intervals and supported by galvanized steel pipes 4, and galvanized steel sheets 2 are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com