A reflective thermal insulation coating

A technology of reflective thermal insulation coating and silicophosphoric acid, which is used in reflective/signal coatings, anti-corrosion coatings, antifouling/underwater coatings, etc., can solve the problems of insufficient comprehensive performance of coatings, poor storage stability, and single film-forming substances. To achieve the effect of being conducive to heat insulation, fast curing speed, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

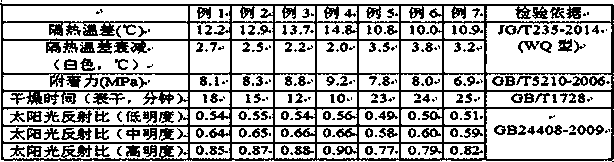

Examples

Embodiment 1

[0028] A reflective heat-insulating coating, comprising the following components in parts by mass: 50 parts of organosilicon phosphate film-forming ionic polymers, 7 parts of mesoporous silica, 7 parts of alumina nanotubes, 10 parts of water, wetting 1 part of dispersant polyacrylate, 1 part of defoamer polysiloxane, 1 part of glycerin.

[0029] The preparation method of described organosilicon phosphate ester film-forming ionic polymer, comprises the steps:

[0030] 1) Preparation of vinylimidazole salt: Dissolve 10g of vinylimidazole and 15g of 2-methoxyethoxymethyl chloride in 100g of ether, stir and react at room temperature for 4 hours, wash the product with ether for 4 times, and in The solvent was removed by rotary evaporation at room temperature;

[0031] 2) Preparation of film-forming polymer: 10 g of vinyl imidazolium salt, 10 g of bistrimethylsilylated vinyl phosphate, 10 g of vinyl ferrocene, 2,2,2-tris Dissolve 30g of fluoroethyl methacrylate and 0.3g of azobisi...

Embodiment 2

[0034] A reflective heat-insulating coating, comprising the following components in parts by mass: 53 parts of organosilicon phosphate film-forming ionic polymers, 9 parts of mesoporous silica, 9 parts of alumina nanotubes, 12 parts of ethanol, Wet dispersant sodium polyacrylate 1 part, defoamer polysiloxane 1 part, fluorine-modified acrylic leveling agent 1.5 parts, anti-ultraviolet additive UV-360 0.5 parts.

[0035] The preparation method of described organosilicon phosphate ester film-forming ionic polymer, comprises the steps:

[0036] 1) Preparation of vinylimidazole salt: Dissolve 10g of vinylimidazole and 17g of 2-methoxyethoxymethyl chloride in ether 130, stir and react at room temperature for 5 hours, wash the product 5 times with ether, And the solvent was removed by rotary evaporation at room temperature;

[0037] 2) Preparation of film-forming polymer: 13g of vinyl imidazolium salt, 10g of bistrimethylsilylated vinyl phosphate, 10g of vinyl ferrocene, 2,2,2-tris ...

Embodiment 3

[0040] A reflective heat-insulating coating, comprising the following components in parts by mass: 56 parts of organosilicon phosphate film-forming ionomers, 10 parts of mesoporous silica, 10 parts of alumina nanotubes, 13 parts of isopropanol, 2 parts of anti-settling agent polyethylene wax, 1 part of anti-ultraviolet additive, 1 part of defoamer Deqian 3100, 1 part of antifreeze agent sodium nitrite.

[0041] The preparation method of described organosilicon phosphate ester film-forming ionic polymer, comprises the steps:

[0042] 1) Preparation of vinylimidazole salt: Dissolve 10g of vinylimidazole and 18g of 2-methoxyethoxymethyl chloride in 140g of ether, stir and react at room temperature for 5.5 hours, wash the product with ether for 6 times, and in The solvent was removed by rotary evaporation at room temperature;

[0043] 2) Preparation of film-forming polymer: 17g of vinylimidazolium salt, 10g of bistrimethylsilylated vinyl phosphate, 10g of vinyl ferrocene, 2,2,2-tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com