A kind of biodegradable environmental protection lubricating oil

A technology of biodegradation and lubricating oil, applied in the field of lubricating oil, can solve the problems of poor oxidation stability of vegetable oil, poor low temperature performance and small application field, and achieve the effects of good biodegradability, good low temperature performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

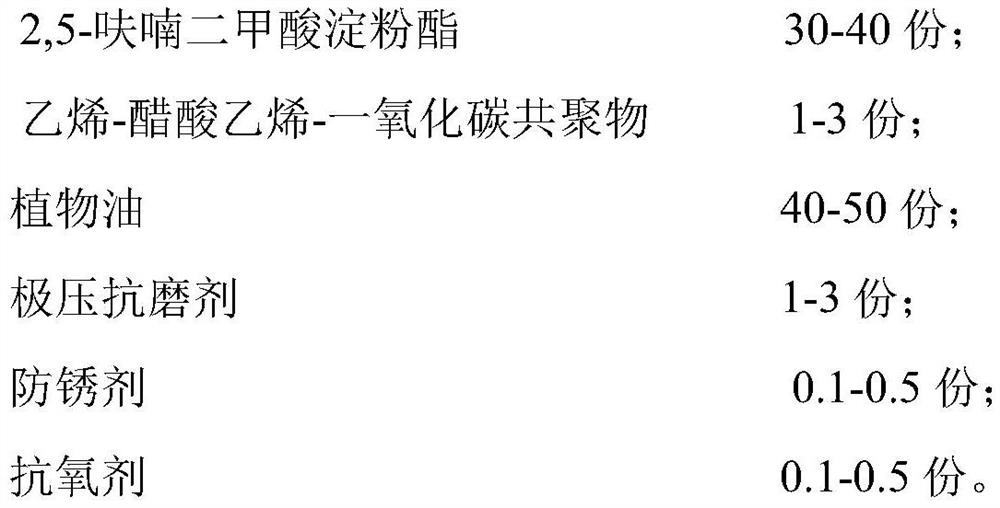

[0025] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0026]

[0027] Wherein, the preparation method of the 2,5-furandicarboxylic acid starch ester comprises the following steps: dissolving 20 g of 2,5-furandicarboxylic acid in 180 g of tetrahydrofuran, and then adding 10 g of starch, 30 g of carbodiimide, 4-diimide Methylaminopyridine 15g, stirred in an ice-water bath for 2 hours, then refluxed and stirred at 40°C for 18 hours, then filtered, diluted with tetrahydrofuran, washed 3 times with water, washed 4 times with saturated saline, absorbed by anhydrous magnesium sulfate, filtered , and then remove the solvent by rotary evaporation at 50°C;

Embodiment 2

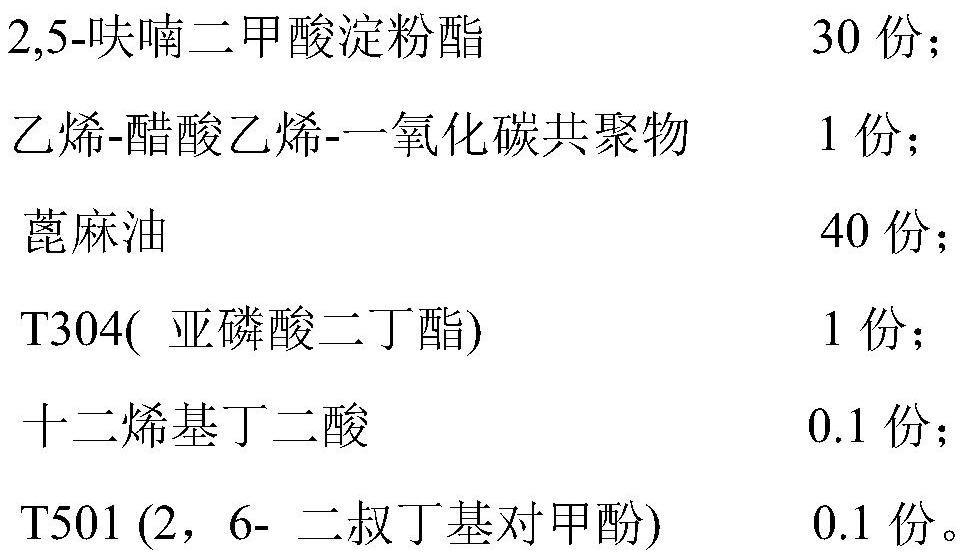

[0029] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0030]

[0031] Wherein, the preparation method of the 2,5-furandicarboxylic acid starch ester comprises the following steps: dissolving 20 g of 2,5-furandicarboxylic acid in 200 g of tetrahydrofuran, and then adding 11 g of starch, 30 g of carbodiimide, 4-diimide Methylaminopyridine 20g, stirred in an ice-water bath for 2.3 hours, then refluxed and stirred at 43°C for 20 hours, then filtered, diluted with dichloromethane, washed 4 times with water, washed 5 times with saturated saline, and absorbed by anhydrous magnesium sulfate , filtered, and then rotary evaporated at 53 ° C to remove the solvent;

Embodiment 3

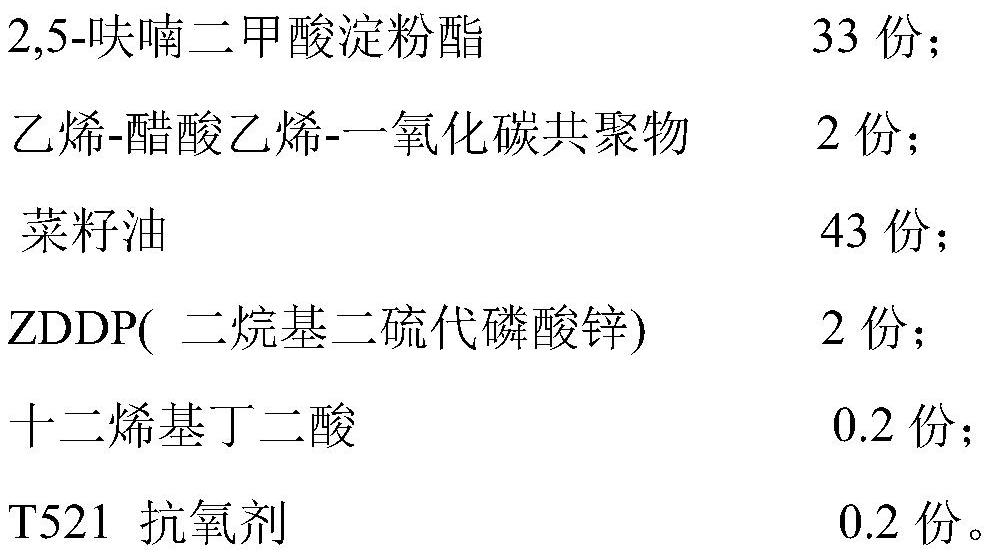

[0033] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0034]

[0035] Wherein, the preparation method of starch 2,5-furandicarboxylate comprises the following steps: dissolving 20 g of 2,5-furandicarboxylic acid in 220 g of tetrahydrofuran, and then adding 12 g of starch, 36 g of carbodiimide, 4-diimide Methylaminopyridine 22g, stirred in an ice-water bath for 2.5 hours, then refluxed and stirred at 45°C for 22 hours, then filtered, diluted with ethyl acetate, washed 5 times with water, washed 6 times with saturated saline, and absorbed by anhydrous magnesium sulfate , filtered, and then rotary evaporated at 56 ° C to remove the solvent;

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com