Normal-pressure filling equipment used for uniform medicine filling

A filling equipment and uniform technology, which is applied in the field of normal pressure filling machines, can solve problems such as machine damage, poor fluidity, and unsmooth discharge, and achieve the effect of preventing deliquescence and odor, and avoiding moisture and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

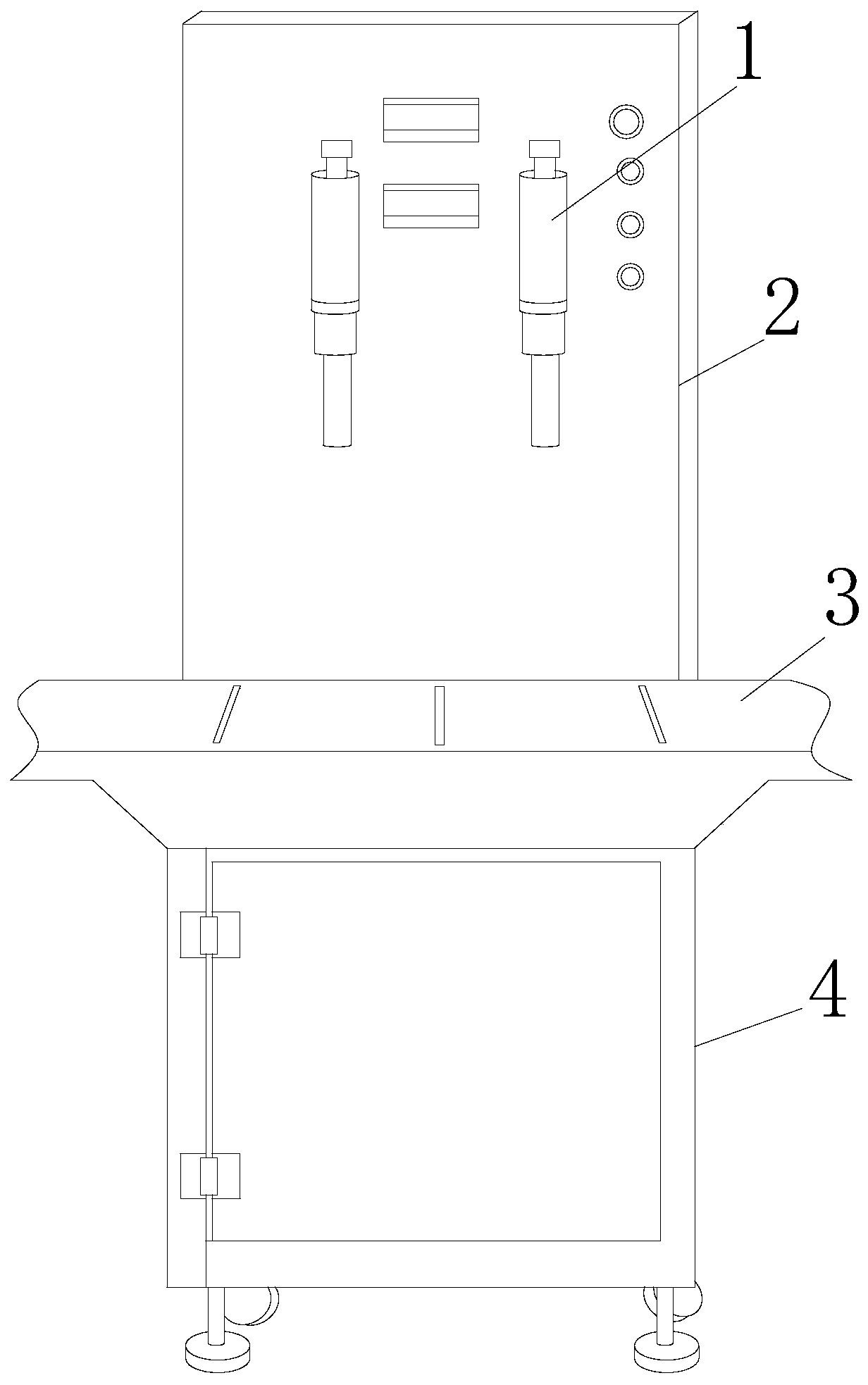

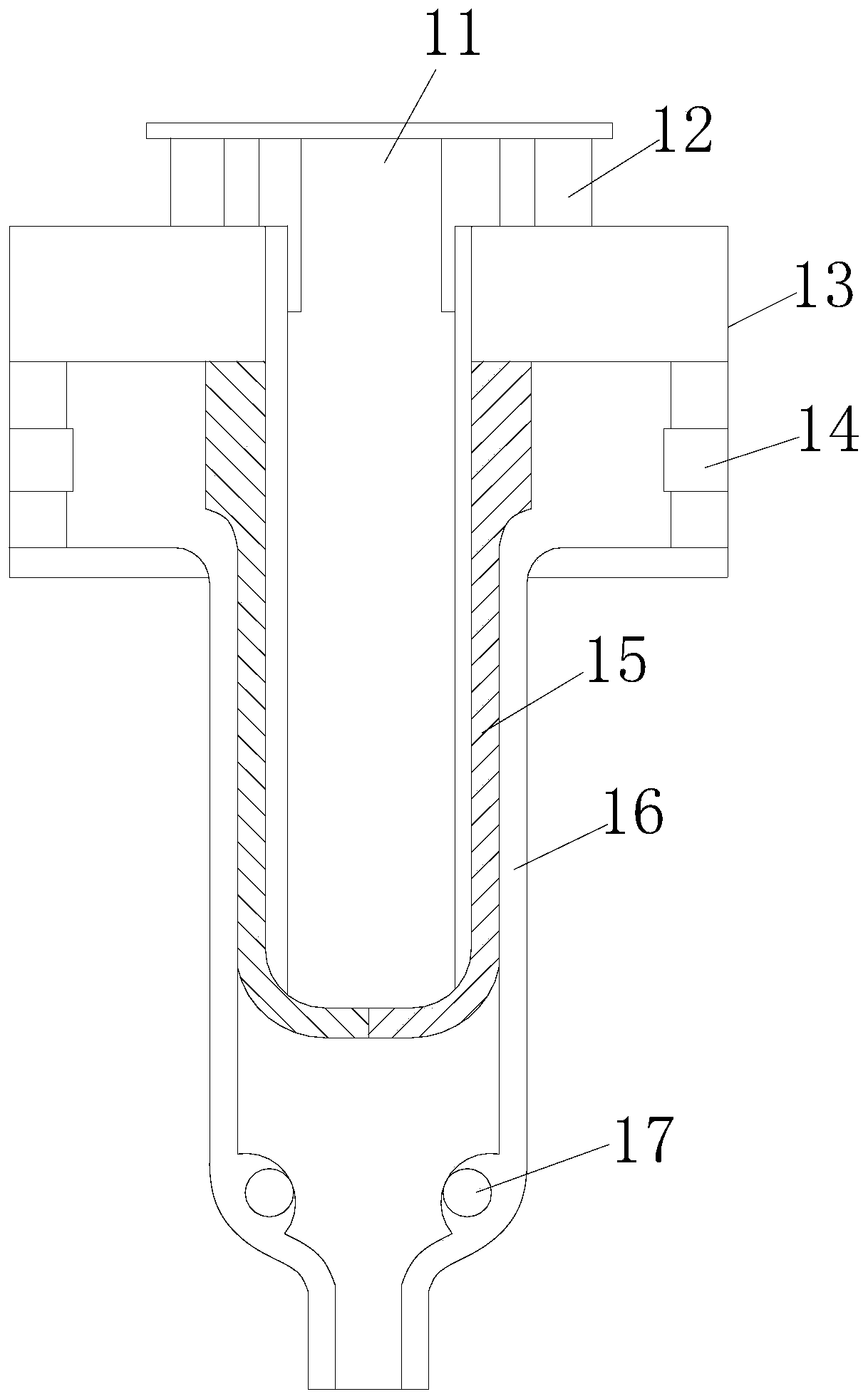

[0029] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of normal-pressure filling equipment for uniform filling of medicines, and its structure includes a liquid outlet pipe 1, a liquid outlet box 2, a conveying platform 3, and a chassis 4, and the conveying platform is installed on the chassis 4 3. The conveying table 3 is matched with the liquid outlet pipe 1, the liquid outlet pipe 1 is arranged on the liquid outlet box 2, the liquid outlet box 2 is controlled by the chassis 4, and the liquid outlet pipe 1 is composed of a die 11. Pressing table 12, tube shell 13, pressure pump 14, sealing guide 15, conduit 16, pressure chamber 17, the top of the tube core 11 is fixed with a pressing table 12, and the pressing table 12 is connected with the tube shell The inside of 13 is connected by upper and lower fit. The inside of the tube shell 13 is provided with a pressure pump 14 and a sealing guide 15. The pressure outlet of the pressure pump 14 communica...

Embodiment 2

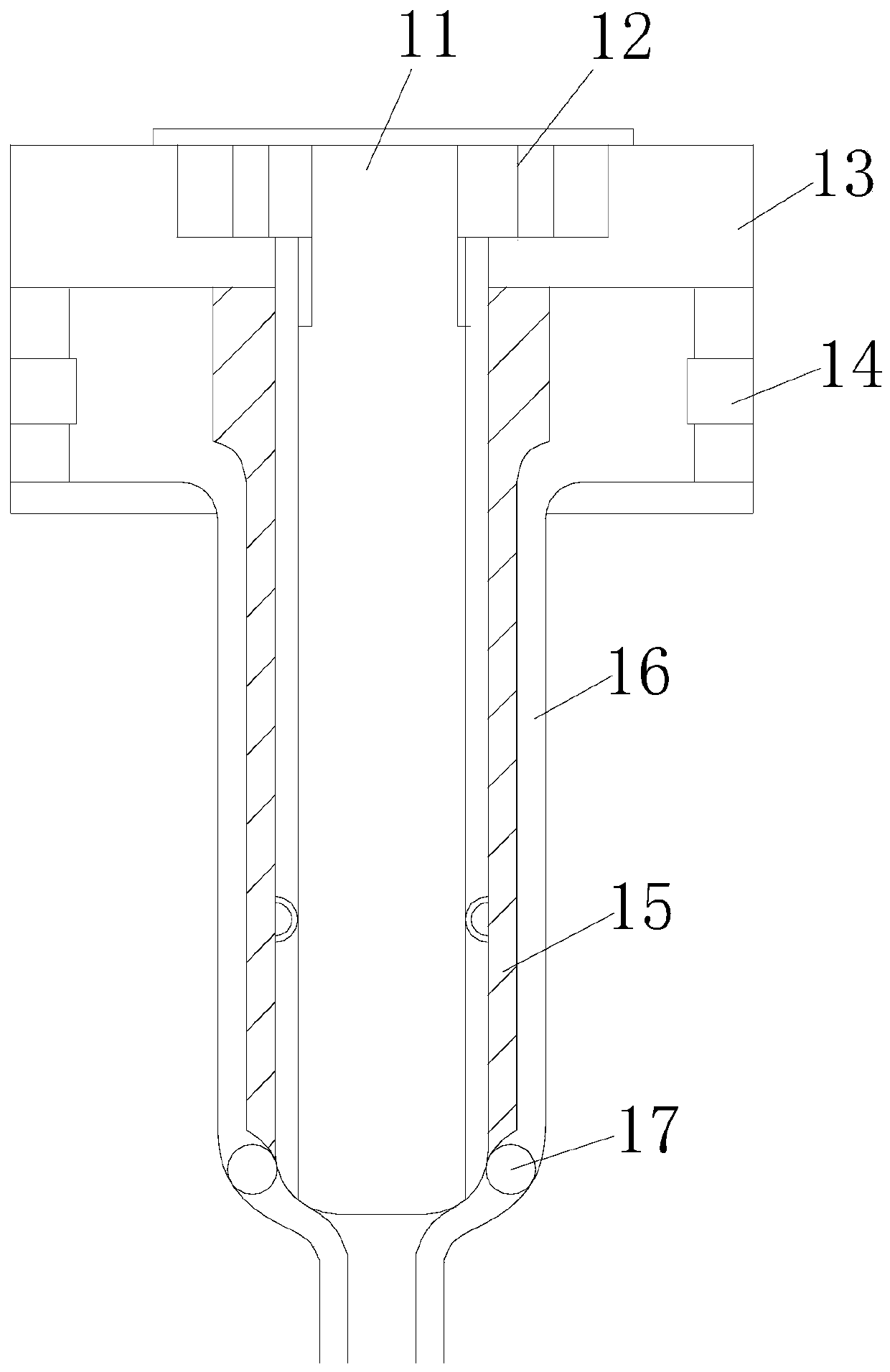

[0031] Such as Figure 4-Figure 6 As shown, on the basis of Embodiment 1, the raised platform 152 includes an inlet 52a, a gasket 52b, a nozzle sleeve 52c, a hollow tube 52d, and a channel 52e, and the inlet 52a is set toward the side of the runner 153, The inlet 52a communicates with the channel 52e, the nozzle cover 52c is fixed on the gasket 52b, and wrapped on the outer surface of the hollow tube 52d, the bottom of the hollow tube 52d is arranged in the channel 52e, and the tube The muzzle 52c includes a compression spring 2c1, a corrugated sheet 2c2, a sealing plate 2c3, and a connecting groove 2c4. The compression spring 2c1 and the connecting groove 2c4 are arranged in parallel, and the connecting groove 2c4 is hingedly connected with a sealing plate 2c3. The sealing plate One end of the 2c3 contacting and sealing is a circular structure, and the outer side of the upper end of the sealing plate 2c3 is provided with a corrugated sheet 2c2, and the top end of the hollow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com