Tool for carrying large-size rectangular glass

A large-size, rectangular technology, applied in the field of tooling for large-size rectangular glass handling, can solve the problems of large-size rectangular glass being easily broken and low efficiency of tooling disassembly, etc., to achieve the goal of reducing glass movement, uniform force, and fast loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

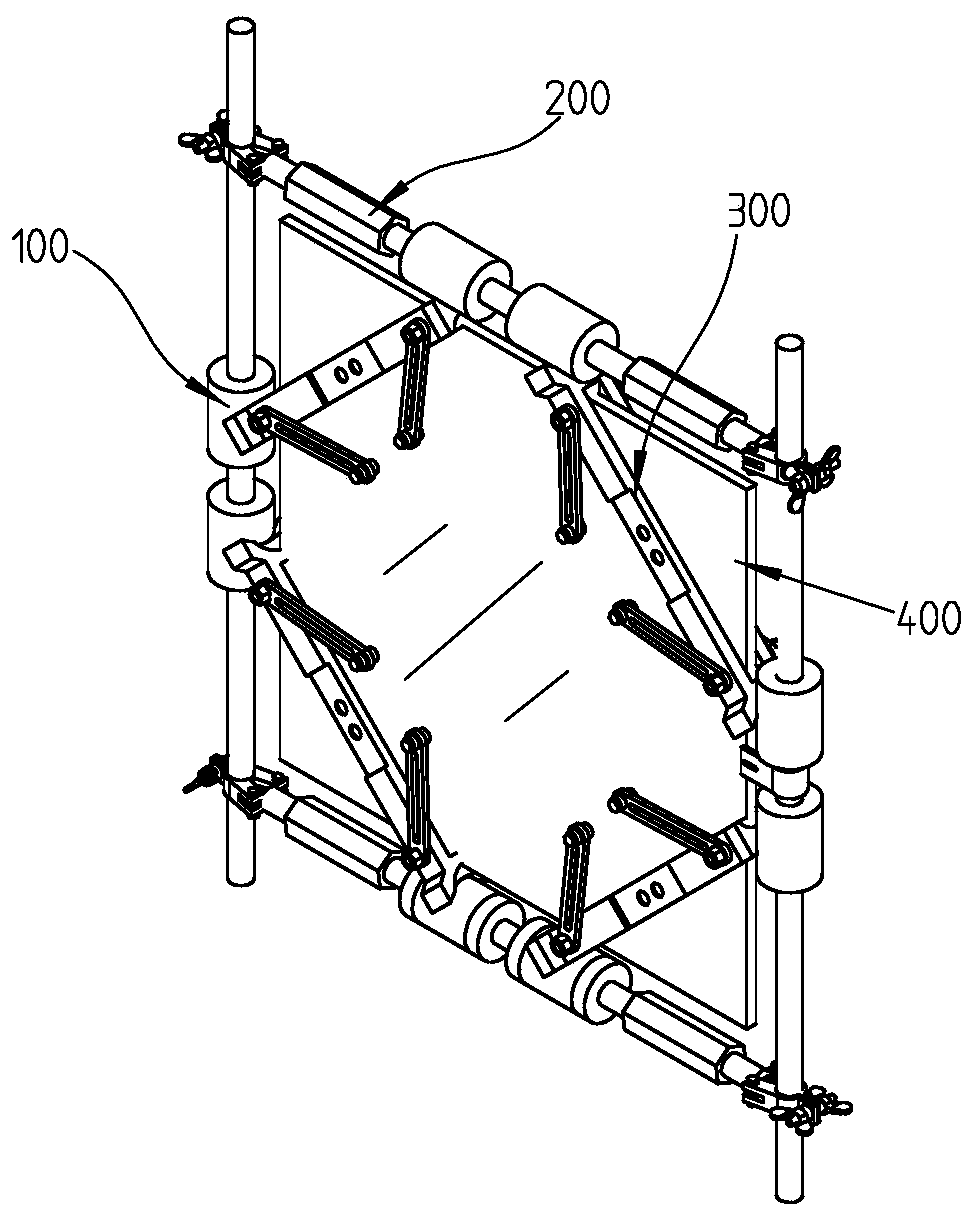

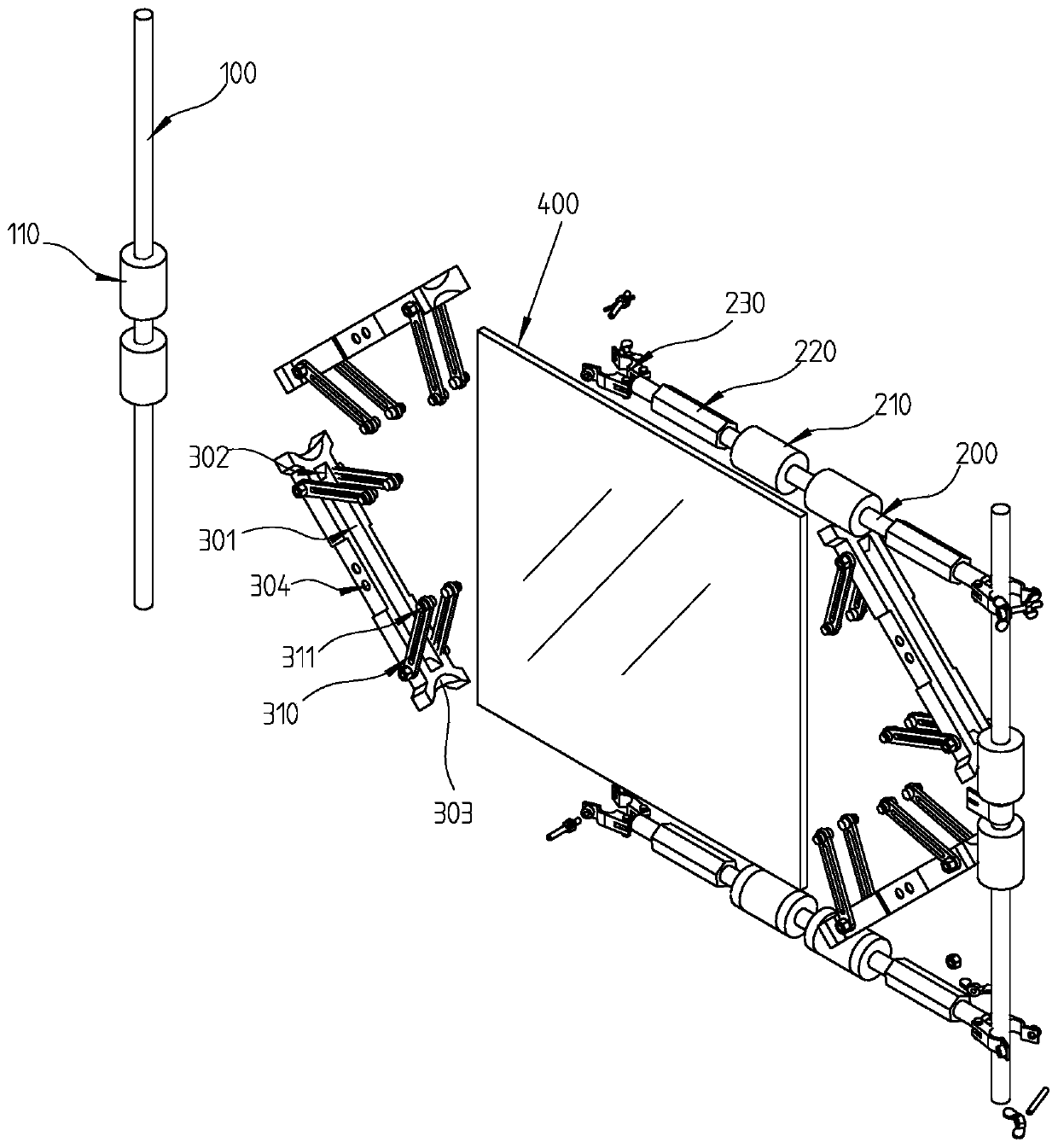

[0023] In a specific embodiment, a tool for handling large-size rectangular glass (such as Figure 1-Figure 2 shown), including corner plates 300 respectively installed at the corners of the rectangular glass, wherein the corner plates 300 are provided with through notches 301 . During installation, the four corner plates 300 are respectively sleeved on the top corners of the rectangular glass through the slots 301. After the sleeves, the top corners of the glass are placed in the slots 301, and the top corners ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap