Steel thin belt casting blank deviation preventing device

A thin steel strip and anti-deviation technology, which is applied in the direction of thin material handling, transportation and packaging, and coiling strips, can solve the problems of poor flexibility, troublesome installation, and poor anti-deviation effect, so as to improve flexibility, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

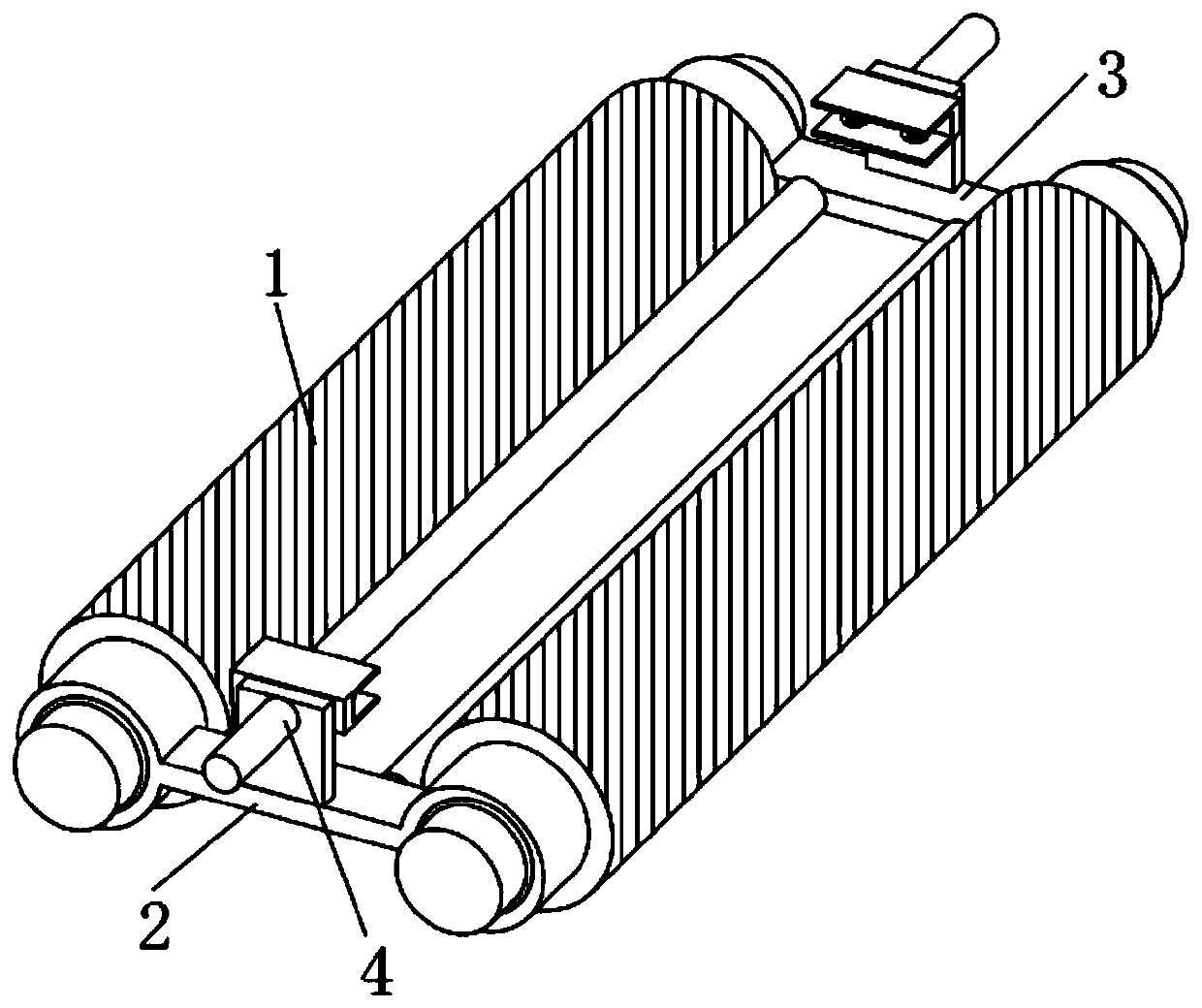

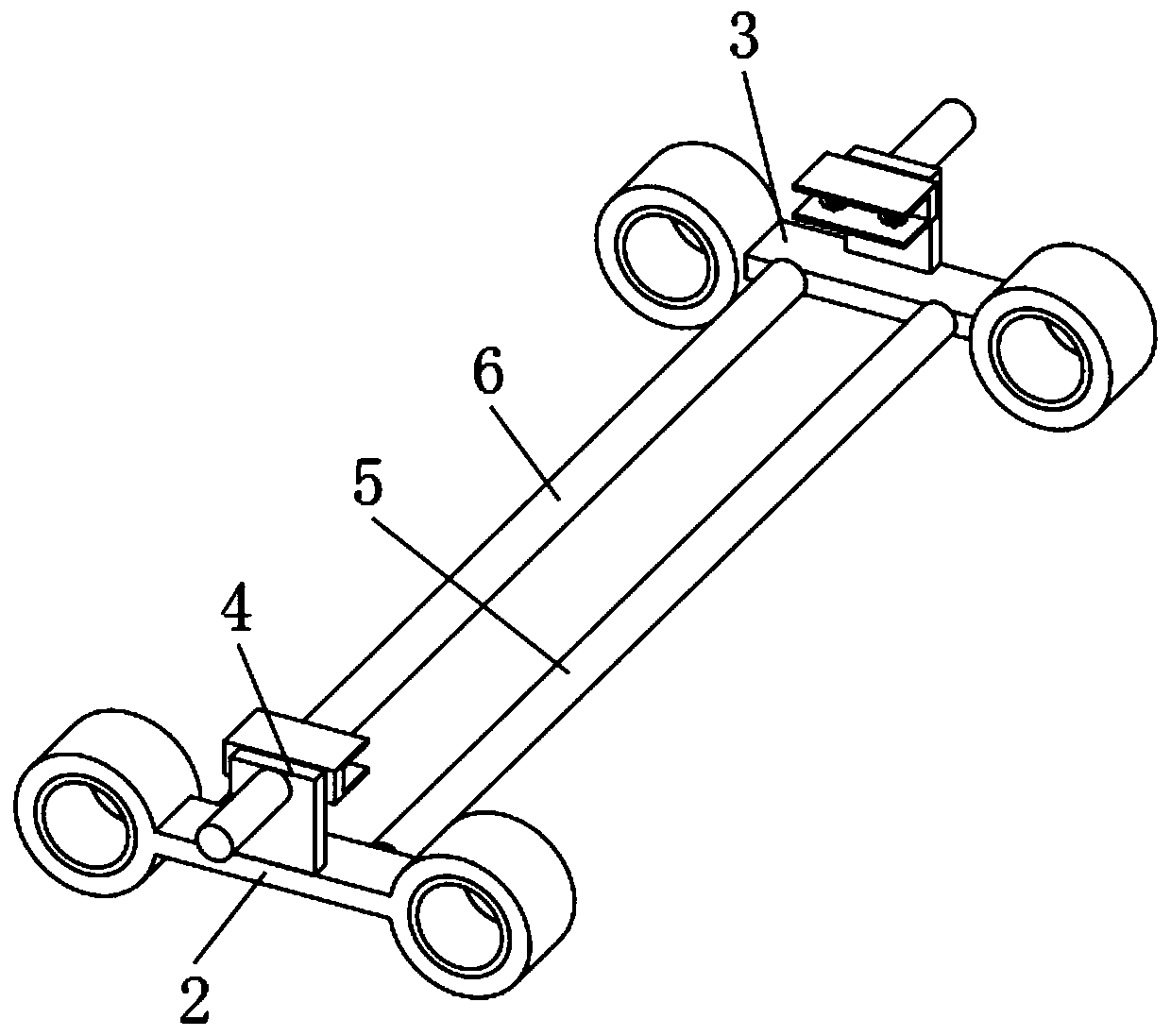

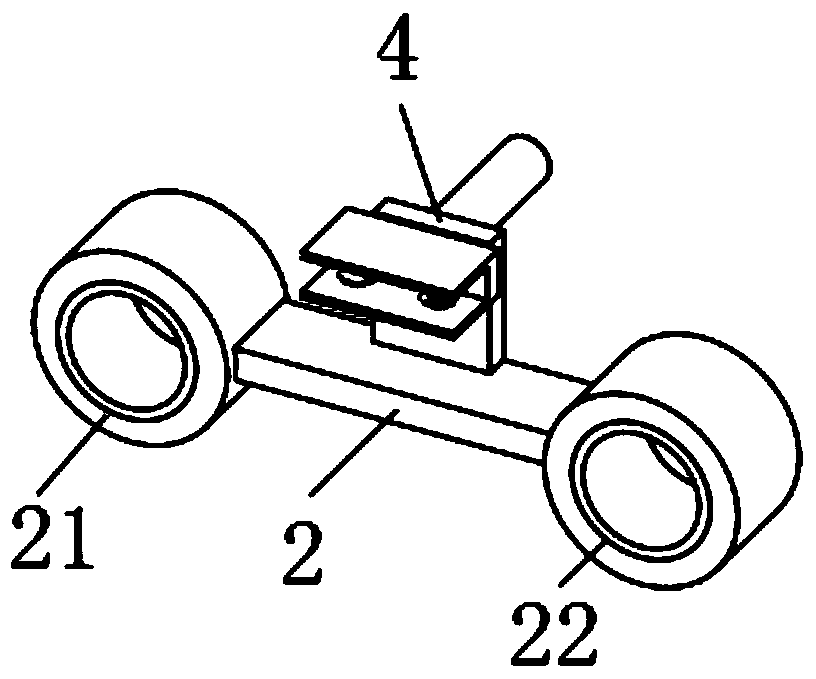

[0031] refer to Figure 1-4 , a thin steel strip casting slab anti-deviation device, comprising: two steel thin strip slab conveying rollers 1 arranged parallel to each other, and also includes a first connecting end frame 2, a second connecting end frame 3 and a limit mechanism 4 ;

[0032] The first connecting end frame 2 and the second connecting end frame 3 are respectively connected to the two ends of two steel thin strip conveying roller shafts 1 arranged parallel to each other;

[0033] The limit mechanism 4 is used to limit the delivery of the steel thin strip, and there are two limit mechanisms 4, and the two limit mechanisms 4 are respectively arranged on ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap