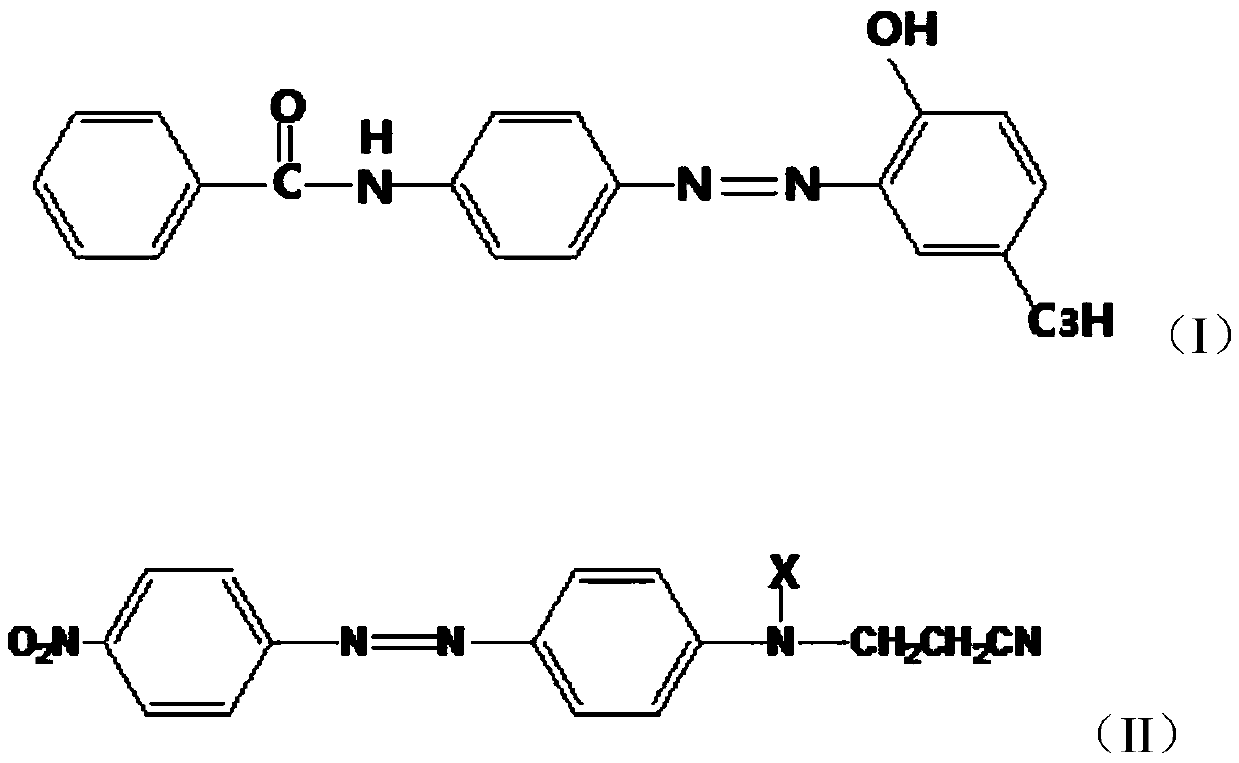

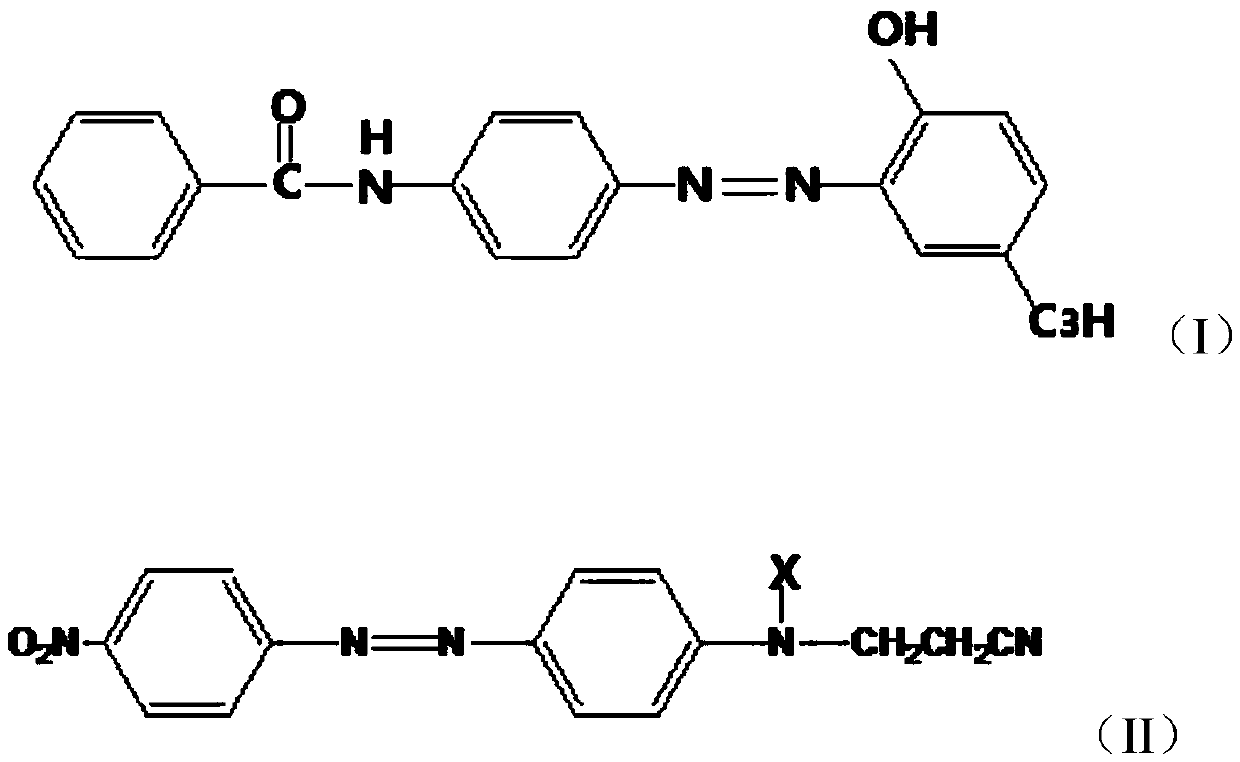

Disperse yellow dye composition and preparation method thereof

A technology of dye composition and dye compound, which is applied in the field of dyes, can solve the problems of poor sublimation fastness, poor compatibility, and yellowing of dyes, and achieve the advantages of sublimation fastness, low price, and wide application range of pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

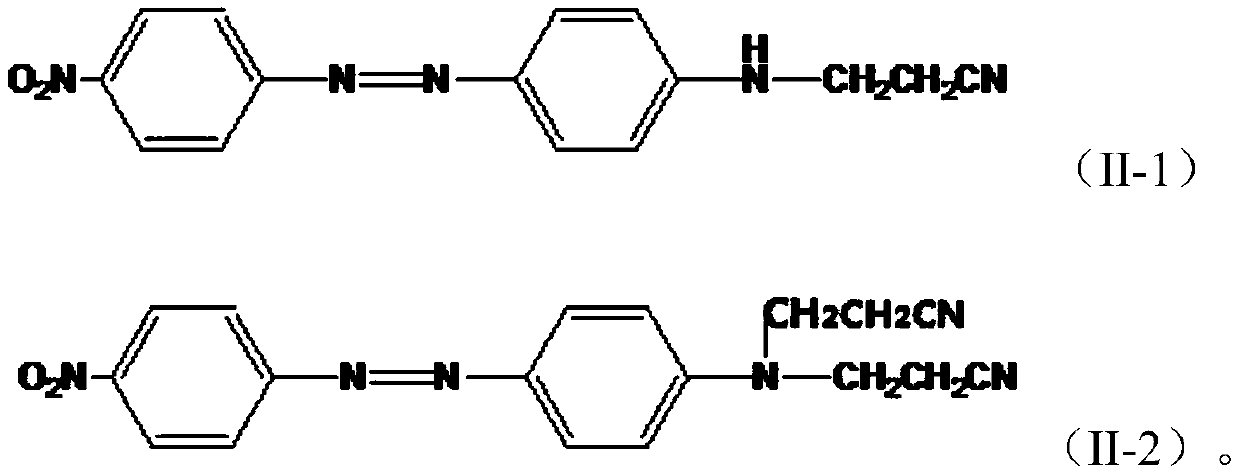

Method used

Image

Examples

Embodiment 1

[0027] After mixing 40 grams of formula (I) compound, 10 grams of formula (II-1) compound, 1 gram of formula (II-2) compound, 53 grams of dispersant MF, and adding 160 grams of water, grind and disperse, spray dry, A finished product is obtained which provides a yellow shade to the fabric.

Embodiment 2

[0029] The disperse dye of embodiment 2-17 is prepared according to the method described in embodiment 1, difference is to adopt the weight ratio of component A, component B in the table below and auxiliary agent, add water and make slurry after blending, control the density of slurry The solid content is preferably 35-45%. Grinding and dispersing, and spray drying to obtain a finished product can provide fabrics with uniform yellow hue and good fastness performance. The auxiliaries in the following table are represented by abbreviations, respectively: dispersant MF is methylnaphthalenesulfonic acid formaldehyde condensate, diffusing agent NNO is naphthalenesulfonic acid formaldehyde condensate, diffusing agent CNF is benzylnaphthalenesulfonic acid formaldehyde condensate, Lignin 85A and 83A are different specifications of sodium lignosulfonate.

[0030] Table 1:

[0031]

[0032] The disperse dyes prepared in the above-mentioned Examples 1 to 17, the disperse dyes in Comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap