A kind of superhydrophobic composite coating on titanium surface and preparation method thereof

A composite coating and super-hydrophobic technology, which is applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of polluting environmental technology, limited thickness, easily damaged substrate, etc., and achieve safe and easy operation in the operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

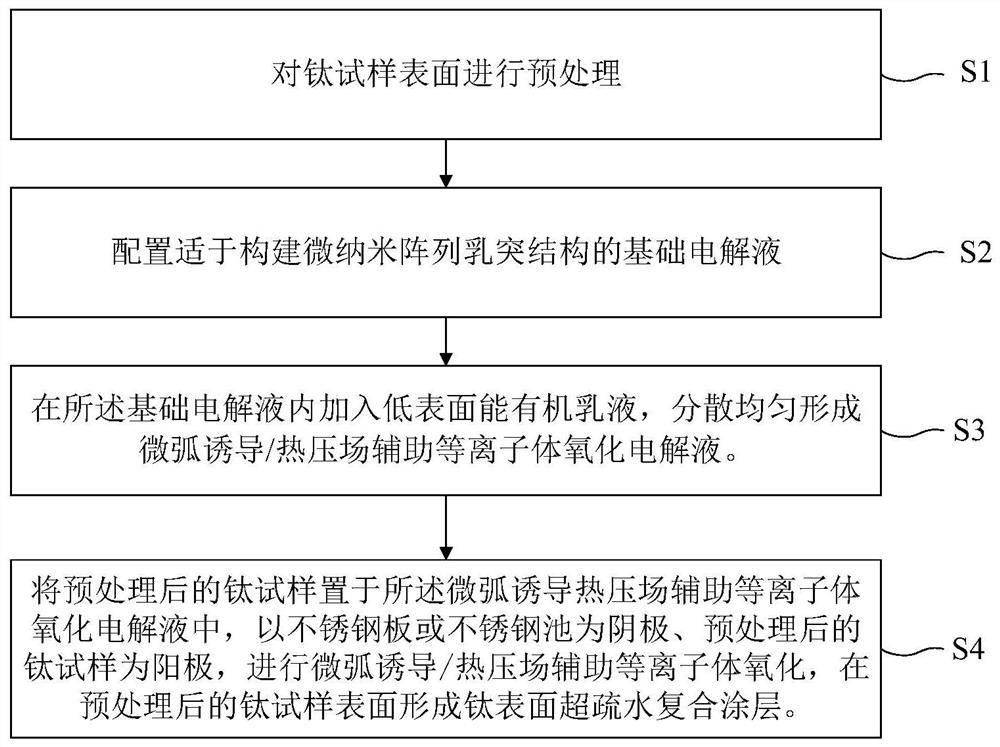

[0036] combine figure 1 Shown, the invention provides a kind of preparation method of titanium surface superhydrophobic composite coating, comprising:

[0037] S1, pretreating the surface of the titanium sample;

[0038] S2, configure the basic electrolyte suitable for constructing the micro-nano array mastoid structure;

[0039] S3. Add a low surface energy organic emulsion into the basic electrolyte, and disperse evenly to form a micro-arc induction / thermal pressure field assisted plasma oxidation electrolyte;

[0040] S4. Place the pretreated titanium sample in the micro-arc induction / thermal pressure field assisted plasma oxidation electrolyte, use the stainless steel plate or stainless steel pool as the cathode, and the pretreated titanium sample as the anode, conduct micro Arc-induced / hot pressure field-assisted plasma oxidation forms a superhydrophobic composite coating on the surface of the pretreated titanium sample.

[0041] Therefore, by optimizing the basic elec...

Embodiment 1

[0070] This embodiment provides a method for preparing a superhydrophobic composite coating on a titanium surface, and the specific steps are as follows:

[0071] 1. Choose TA15 titanium alloy as the substrate, polish the surface with 800#, 1000# and 1500# sandpaper in turn, and then ultrasonically clean it with acetone and deionized water for 20 minutes respectively;

[0072] 2. Mix with sodium silicate hydrate 20g / L, sodium metaphosphate 6g / L, and sodium hydroxide 2g / L, that is, the concentration ratio of sodium silicate, sodium metaphosphate and sodium hydroxide is 10:3:1 , mechanically stirred evenly, the electrolyte system is optimized to prepare the basic electrolyte with micro-nano array papillae structure;

[0073] 3. Add 20% volume fraction of polytetrafluoroethylene (PTFE) emulsion into the uniform basic electrolyte, and disperse it ultrasonically for 40 minutes to prepare a micro-arc induction / thermal pressure field assisted plasma oxidation electrolyte with good un...

Embodiment 2

[0077] The difference between this embodiment and the above-mentioned embodiment 1 is that a method for preparing a superhydrophobic composite coating on a titanium surface is provided, and the specific steps are as follows:

[0078] 1. Choose TA15 titanium alloy as the substrate, polish the surface with 800#, 1000# and 1500# sandpaper in sequence, and then ultrasonically clean it with acetone and deionized water for 30 minutes respectively;

[0079] 2. Mix in the ratio of hydrated sodium silicate 18g / L, sodium metaphosphate 6g / L, and sodium hydroxide 3g / L, that is, the concentration ratio of sodium silicate, sodium metaphosphate and sodium hydroxide is 6:2:1 , mechanically stirred evenly to obtain a basic electrolyte;

[0080] 3. Add 20% volume fraction of polytetrafluoroethylene (PTFE) emulsion into the uniform basic electrolyte, and disperse it ultrasonically for 60 minutes to prepare a micro-arc induction / hot pressure field assisted plasma oxidation electrolyte with good u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com