Arrangement method of linear adjustment and vibration reduction structure for cable rail high overhead rail structure

A technology of vibration-reducing structure and layout method, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of aggravating upper stability and structural torsional vibration, and achieve the effects of reducing lateral torsional vibration, improving stability, and improving driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

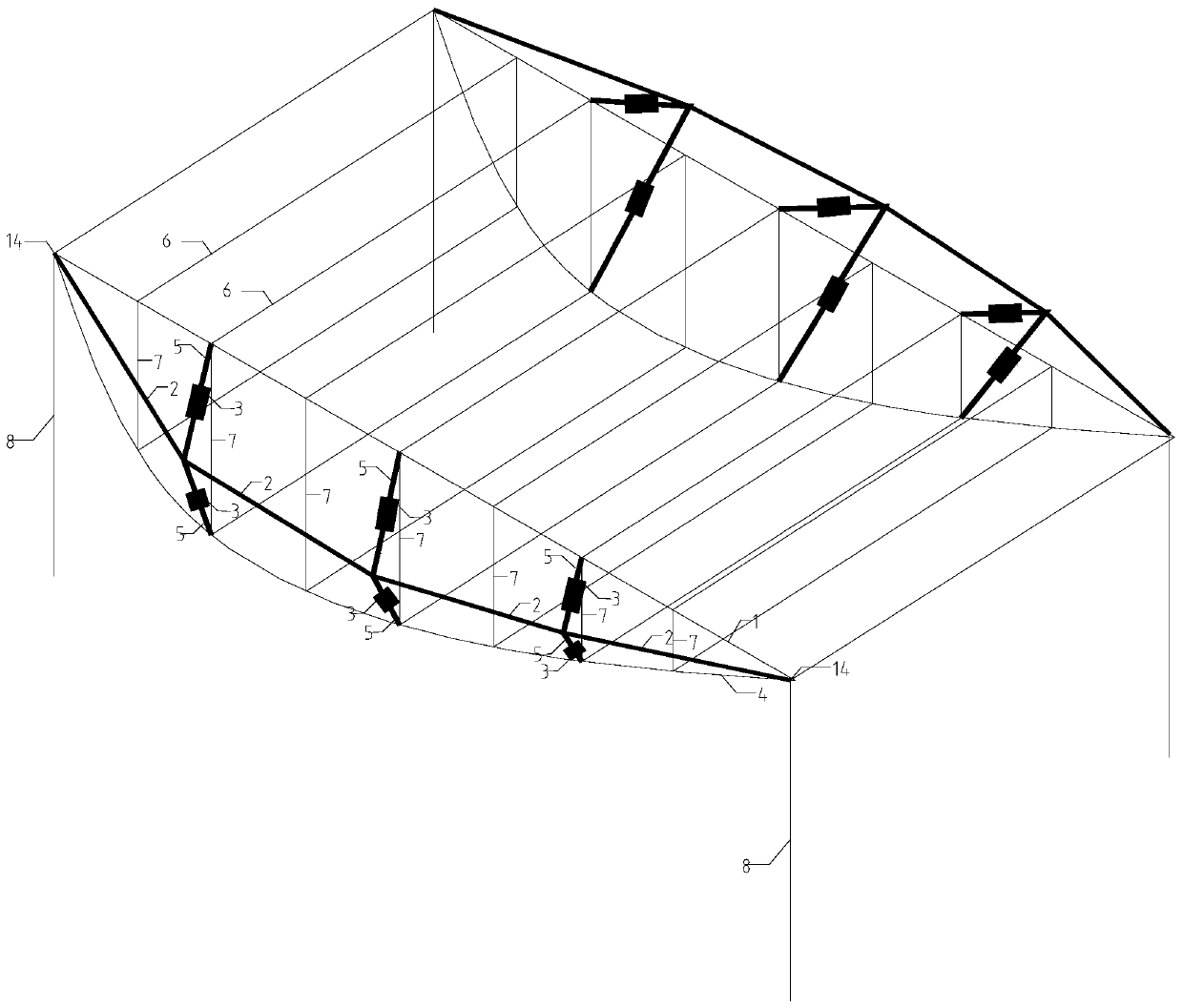

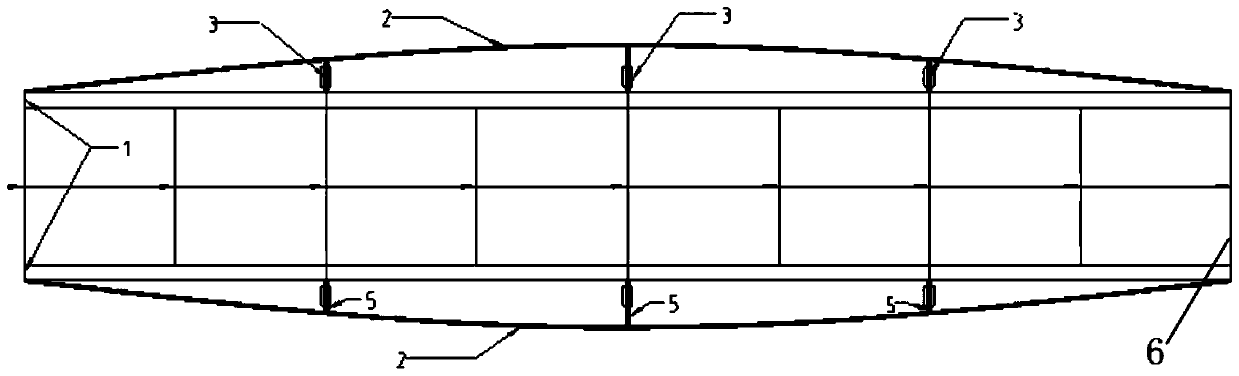

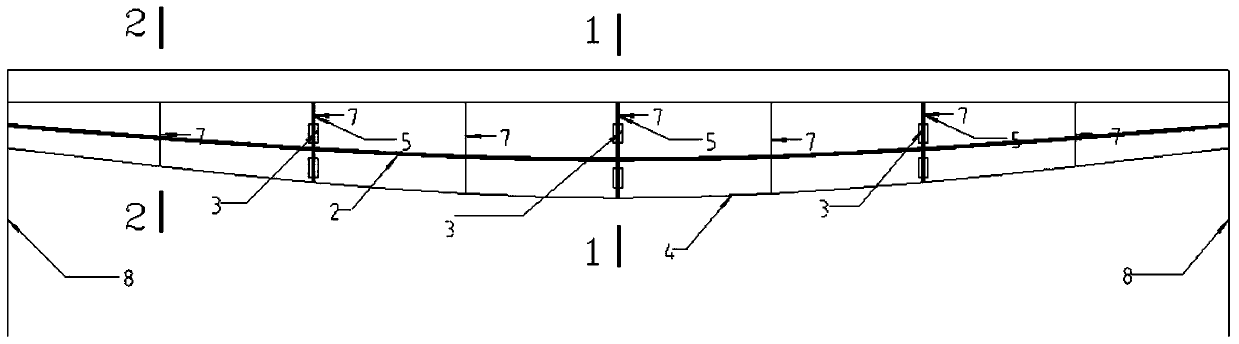

[0030] like Figure 1-5 Shown in , 8: a kind of arrangement method that is used for the linear adjustment of cable rail elevated aerial rail structure and damping structure, existing empty rail structure comprises two parallel tracks 1 and the main cable that is respectively positioned at the bottom of track 1 4. The two parallel rails 1 are connected by transverse connecting rods 6, the rails 1 and the main cables 4 below them are connected by vertical struts 7, and supporting piers 8 are provided around the bottom of the empty rail structure; It is characterized in that it comprises the following steps:

[0031] Step 1: Install the tie rod cable 2;

[0032] In view of the deflection caused by the asymmetry of the main cable 4 force on both sides of the existing empty track structure, a bundle of tie rod cables 2 is installed on both sides of the empty track structure, and the tie rod cables 2 are respectively located on the structural plane of the track 1 and the main cable...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap